Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

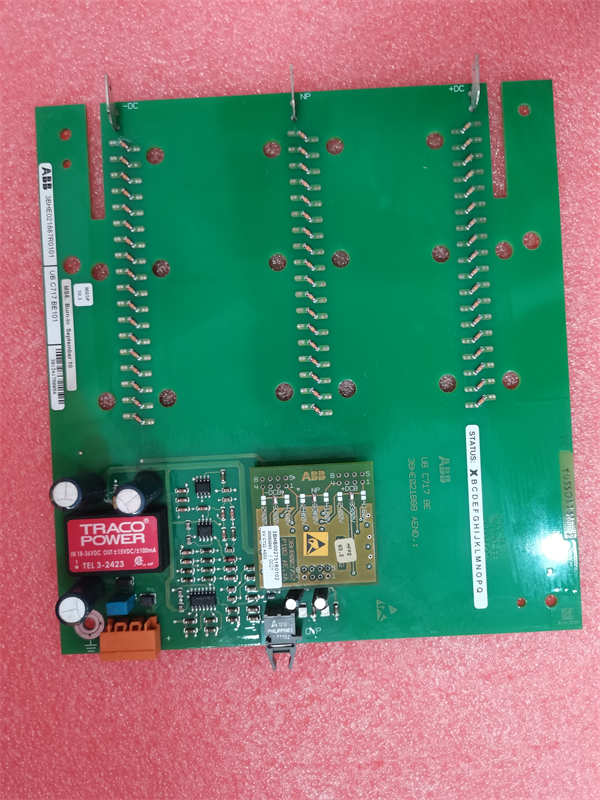

| Product Model | UBC717BE101 / 3BHE021887R0101 |

| Manufacturer | ABB |

| Product Category | PROFIBUS DP Master Interface Module |

| Compatible Controller | AC 800M (PM865, PM866, PM891) |

| PROFIBUS Standard | EN 50170 DP-V0/V1, IEC 61158 |

| Data Transfer Rate | 9.6 kbps – 12 Mbps (auto-negotiating) |

| Number of Ports | 2 independent PROFIBUS channels |

| Max Devices per Channel | 124 slaves |

| I/O Data Capacity | 244 bytes input + 244 bytes output per slave |

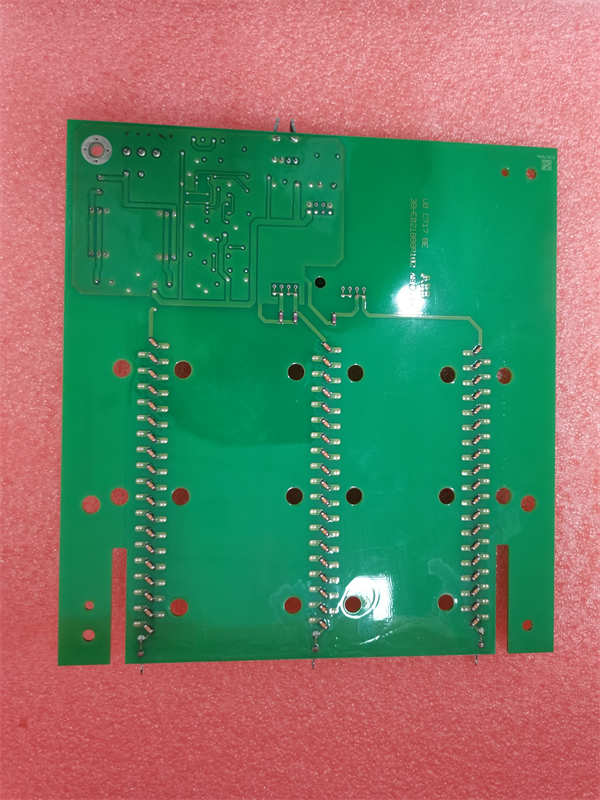

| Interface Type | 9-pin D-sub (Channel A/B) |

| Isolation | 500V AC (fieldbus to controller) |

| Power Consumption | 1.8W @ 5V DC (backplane) |

| Operating Temperature | -25°C to +70°C |

| Certifications | UL 508, CE, IEC 61800-3, RoHS 2 |

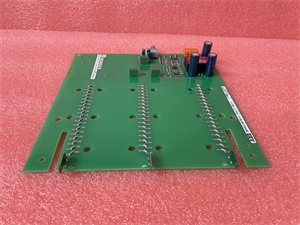

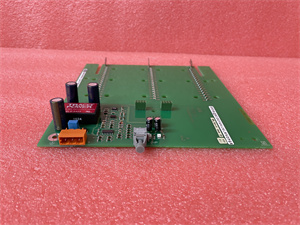

ABB UBC717BE101 3BHE021887R0101

Product Introduction

The ABB UBC717BE101 3BHE021887R0101 is a high-performance PROFIBUS DP Master communication module designed for ABB’s AC 800M programmable automation controllers. As a critical component of the 800xA and Symphony Plus control systems, this module enables deterministic real-time communication between AC 800M processors and distributed field devices (sensors, drives, I/O stations) across industrial networks. Its primary function is to manage PROFIBUS DP-V0/V1 networks, handling cyclic data exchange, diagnostics, and slave parameterization while ensuring precise synchronization for motion control and process applications.

Technically positioned as a dual-channel network interface, the UBC717BE101 operates at the controller level, directly interfacing with AC 800M’s PCI bus. Unlike basic communication cards, it supports advanced PROFIBUS features like DPV1 non-cyclic services, SYNC/FREEZE commands, and redundant media configurations. Within ABB’s architecture, this module transforms the AC 800M into a powerful DP master capable of managing complex automation topologies – from discrete manufacturing lines to continuous process plants – while providing millisecond-level determinism essential for safety-critical operations.

Core Advantages and Technical Highlights

Dual-Channel Redundancy & High Availability:

The UBC717BE101 features two fully independent PROFIBUS channels, enabling redundant network topologies for mission-critical applications. If one channel fails, the other maintains communication, significantly reducing single points of failure. This is essential for safety systems (SIL 2) and high-availability processes like power generation or pharmaceutical manufacturing.

Deterministic Performance:

Engineered for real-time control, the module achieves ≤1 ms cycle times for 32 devices with 244 bytes of I/O. Hardware-based processing eliminates CPU load fluctuations, ensuring consistent jitter below 50 μs – critical for synchronized drive systems and high-speed packaging lines.

Advanced Diagnostics & Auto-Configuration:

Integrated diagnostic LEDs per channel (RUN/BUSF/DP-ACT) provide instant fault localization. The module automatically detects baud rates (9.6kbps–12Mbps) and performs topological scans using ABB’s Control Builder. Detailed network diagnostics (slave status, telegram errors, signal quality) are accessible via engineering tools.

Seamless Integration with ABB Ecosystem:

Direct PCI bus connection to AC 800M controllers (PM865/PM891) eliminates protocol conversion delays. Native support in Control Builder M allows drag-and-drop configuration of PROFIBUS slaves. Compatible with ABB’s S800 I/O via KVC758A slave interfaces.

Robust Industrial Design:

With 500V isolation, extended temperature range (-25°C to +70°C), and conformal-coated PCB, the UBC717BE101 withstands harsh environments like steel mills or offshore platforms. Auto-termination detection simplifies cabling.

Typical Application Scenarios

Automotive Production Lines: Controls robotic cells and transfer systems using PROFIBUS drives. Dual-channel redundancy of the UBC717BE101 prevents line stoppages during communication faults.

Cement Plant Kiln Control: Manages weigh feeders, hydraulic units, and temperature sensors across 500m+ distances. The module’s 12Mbps speed ensures real-time control of pyroprocessing.

Offshore Compression Platforms: Interfaces with SIL 2-certified emergency shutdown valves via redundant PROFIBUS PA segments using link couplers.

Paper Machine Drives: Synchronizes >50 sectional drives via PROFIBUS-DP with SYNC commands. Jitter <50μs prevents web tearing at 2,000 m/min speeds.

Pharmaceutical Batch Reactors: Integrates HART multiplexers and flow meters. DPV1 services enable non-cyclic parameter updates during recipe changes.

Water Pumping Stations: Controls remote RTUs and VSDs across flood-prone areas. The module’s corrosion resistance ensures reliability in high-humidity environments.

ABB UBC717BE101 3BHE021887R0101

Related Model Recommendations

PM865K01: High-performance AC 800M CPU – Primary host for the UBC717BE101 module.

KVC758A: PROFIBUS Slave Interface for S800 I/O – Connects ABB’s distributed I/O to UBC717BE101-managed networks.

CI854A: PROFIBUS DP Master (Alternative) – CompactCOMM module for smaller configurations.

SD822: S800 Carrier Power Supply – Powers I/O stations managed by UBC717BE101.

TA527: PROFIBUS Terminator – Required for end-of-line termination in UBC717BE101 networks.

PP825: Redundant Power Supply – Ensures uninterrupted operation for critical controllers using UBC717BE101.

3BSE050091R65: PROFIBUS PA Link Coupler – Extends UBC717BE101 networks to intrinsic safety zones.

CM5720: Communication Module Tester – Validates UBC717BE101 network integrity during commissioning.

AO810: Analog Output Module – Typical slave device controlled via UBC717BE101.

SAI543: IEC 61850 Gateway – For hybrid networks where UBC717BE101 integrates legacy PROFIBUS assets.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Power down the AC 800M controller before installation. Handle the UBC717BE101 using ESD wrist straps. Insert firmly into a compatible PCI slot (verify controller compatibility). Secure with mounting screws. Connect PROFIBUS cables to Channel A/B ports, ensuring shield grounding at one end only. Set slave addresses before power-up.

Maintenance Suggestions: Monitor “BUSF” LED for persistent faults indicating wiring issues. Use Control Builder’s diagnostic viewer to check slave health status quarterly. Clean air vents on controller racks annually to prevent overheating. Backup configuration before firmware updates. For network expansion, verify total cable length <100m per segment at 12Mbps. Replace only with genuine ABB UBC717BE101 modules to ensure compatibility.

Service and Guarantee Commitment

ABB provides a 24-month global warranty for the UBC717BE101 3BHE021887R0101, covering material and workmanship defects. Comprehensive support includes:

24/7 technical assistance via ABB’s Automation Support Hub

Firmware updates for cybersecurity and feature enhancements

On-site commissioning services by certified engineers

Repair/exchange programs with 5-day turnaround

Lifetime product support (minimum 10 years after discontinuation)

Extended warranty options (up to 5 years) include priority replacement and firmware management. Documentation access through ABB’s MyControlSystem portal includes:

Hardware manuals (3BSE050360-600)

Configuration guides

FATS/SATS validation protocols

All repairs use OEM components and comply with IEC 62443 security standards.