Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

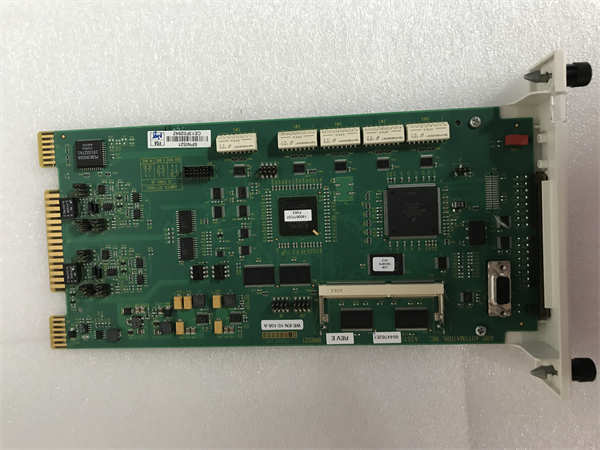

| Product Model | ABB SPNPM22 |

| Manufacturer | ABB |

| Product Category | Network Interface Module |

| Series | S800 I/O System |

| Interface Type | PROFINET IO |

| Data Transfer Rate | 100 Mbps |

| Number of Ports | 2 (RJ45) |

| Power Supply | 24V DC (±10%) |

| Operating Temperature | 0°C to +60°C |

| Protection Rating | IP20 |

| Dimensions (W×H×D) | 45×100×115 mm |

| Protocol Support | PROFINET IO Class A |

| Certifications | CE, UL, IEC 61131-2 |

ABB SPNPM22

Product Introduction

The ABB SPNPM22 is a high-performance PROFINET IO interface module designed for ABB’s S800 I/O system. This advanced communication module enables seamless integration of field devices into industrial Ethernet networks, providing reliable data exchange between controllers and distributed I/O. The SPNPM22 is particularly valuable in automation systems requiring real-time communication and high-speed data transfer.

As part of ABB’s comprehensive industrial automation portfolio, the SPNPM22 module offers robust connectivity solutions for demanding industrial environments. Its compact design and efficient performance make it suitable for various applications in process automation, manufacturing, and energy management systems.

Core Advantages and Technical Highlights

Reliable network connectivity: The ABB SPNPM22 features dual RJ45 ports with auto-crossover functionality, enabling flexible network topologies. The PROFINET IO Class A support ensures deterministic communication for time-critical applications.

Easy integration: With its plug-and-play design, the module simplifies system configuration and reduces commissioning time. The module automatically detects and configures connected devices, streamlining the installation process.

Robust industrial design: Built for harsh environments, the SPNPM22 operates reliably in industrial temperature ranges and features electrical isolation for noise immunity. The compact form factor saves valuable control cabinet space.

Advanced diagnostics: Comprehensive status indicators and built-in diagnostic functions provide real-time monitoring of network health and module performance, enabling proactive maintenance.

Typical Application Scenarios

The ABB SPNPM22 is widely used in:

Automotive manufacturing: Connecting robotic cells and production line equipment to central control systems

Food and beverage processing: Integrating hygienic sensors and actuators into networked automation systems

Pharmaceutical production: Enabling GMP-compliant data collection and process monitoring

Water treatment plants: Facilitating remote monitoring of distributed pumping stations

Power generation facilities: Supporting real-time data acquisition in turbine control systems

ABB SPNPM22

Related Model Recommendations

ABB SPNPM21: Previous generation PROFINET interface module

ABB SPNPB22: PROFIBUS DP interface module for S800 I/O

ABB S800 I/O modules: Various analog and digital I/O modules

ABB AC500 PLC: Compatible programmable controller

ABB CP600 HMI: Operator interface for system monitoring

ABB COM600: Communication gateway for network integration

Installation, Commissioning and Maintenance Instructions

Installation preparation: Ensure proper grounding and adequate clearance for heat dissipation. Verify network infrastructure meets PROFINET requirements before installation.

Commissioning steps: Mount the module on the S800 baseplate and connect network cables. Configure the module using engineering tools like ABB’s Automation Builder. Verify communication with all connected devices.

Maintenance suggestions: Regularly check network connections and status indicators. Monitor communication performance statistics for early detection of potential issues. Keep firmware updated to the latest version for optimal performance and security.

Service and Guarantee Commitment

ABB provides a standard 3-year warranty for the ABB SPNPM22, covering manufacturing defects and component failures. Extended warranty options are available for critical applications. ABB’s global technical support network offers comprehensive assistance, including firmware updates and troubleshooting guidance. Training services are available to help customers maximize the value of their automation investment.