Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PPD113B01-10-150000 3BHE023784R1023 |

| Manufacturer | ABB |

| Product category | Process control module |

| Operating voltage | 24V DC (18-30V DC) |

| Power consumption | Typical: 12W, Maximum: 18W |

| Communication protocols | PROFINET, Modbus TCP/IP |

| I/O interfaces | 8 digital inputs, 4 digital outputs, 2 analog inputs (4-20mA) |

| Operating temperature | -10°C to 60°C |

| Storage temperature | -40°C to 85°C |

| Dimensions (W×H×D) | 120mm×80mm×150mm |

| Weight | Approximately 450g |

| Protection rating | IP20 (module), IP65 (front panel when installed) |

| Certifications | CE, UL 508, IEC 61131-2 |

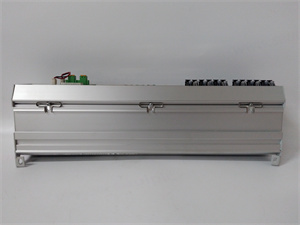

ABB PPD113B01-10-150000 3BHE023784R1023

Product introduction

PPD113B01-10-150000 3BHE023784R1023 is a compact yet powerful process control module from ABB, designed to bridge the gap between field devices and larger automation systems in industrial environments. As part of ABB’s PPD series, which is renowned for reliability in process industries, this module serves as a critical interface for monitoring and controlling discrete and analog processes.

The core function of PPD113B01-10-150000 3BHE023784R1023 lies in its ability to collect real-time data from sensors and actuators, process it locally, and communicate with higher-level systems such as PLCs or DCS. Its balanced combination of digital and analog I/Os makes it versatile for applications ranging from simple machine control to complex process monitoring. In automation systems, PPD113B01-10-150000 3BHE023784R1023 acts as a distributed intelligence node, reducing data traffic to central controllers while enabling faster response to local events.

Core advantages and technical highlights

Dual-protocol flexibility:

PPD113B01-10-150000 3BHE023784R1023 supports both PROFINET and Modbus TCP/IP, eliminating the need for protocol converters in mixed-network environments. This feature simplifies integration into existing systems, whether upgrading from legacy Modbus setups or implementing modern PROFINET architectures, saving up to 30% in integration time compared to single-protocol modules.

Compact design with robust performance:

Despite its small footprint (120mm×80mm×150mm), PPD113B01-10-150000 3BHE023784R1023 delivers reliable operation in harsh industrial conditions, including temperatures up to 60°C. This makes it ideal for installation in tight spaces such as control cabinets in chemical plants or food processing lines, where space is often limited but performance cannot be compromised.

Local processing capabilities:

Unlike basic I/O modules, PPD113B01-10-150000 3BHE023784R1023 features onboard processing that enables simple logic execution at the edge. This allows for local decision-making, such as triggering alarms or activating valves without waiting for commands from a central controller, reducing response times from milliseconds to microseconds in critical applications.

ABB PPD113B01-10-150000 3BHE023784R1023

Typical application scenarios

In chemical processing plants, PPD113B01-10-150000 3BHE023784R1023 is commonly deployed to monitor and control batch mixing processes. Its analog inputs connect to pressure and temperature sensors in reaction vessels, while digital outputs control solenoid valves for chemical dosing. The module’s local processing capability ensures that if temperature exceeds safe limits, it can immediately shut down feed valves—even if communication with the central DCS is temporarily lost—preventing potential safety hazards.

Within water treatment facilities, PPD113B01-10-150000 3BHE023784R1023 integrates with filtration systems, using its digital inputs to track filter status and analog inputs to monitor flow rates. Through PROFINET, it communicates real-time data to the main SCADA system, while its Modbus interface connects to legacy pressure gauges, creating a seamless bridge between new and old equipment. This versatility makes it a cost-effective solution for facilities undergoing gradual modernization.

In food and beverage production lines, PPD113B01-10-150000 3BHE023784R1023 controls filling machines by monitoring bottle presence (digital inputs) and regulating fill levels (analog outputs). Its ability to operate in temperature-fluctuating environments (-10°C to 60°C) ensures reliable performance in both cold storage areas and near steam-based cleaning systems, maintaining production continuity in hygiene-critical operations.

Related model recommendations

- PPD112B01-10-150000 3BHE023783R1022: A lower I/O variant with 6 digital inputs and 2 analog inputs, suitable for smaller-scale applications where full capabilities of PPD113B01-10-150000 3BHE023784R1023are unnecessary.

- PPD114B01-10-150000 3BHE023785R1024: Higher-end model with 16 digital I/Os and 4 analog inputs, serving as an upgrade path from PPD113B01-10-150000 3BHE023784R1023in expanding systems.

- AC500 PLC: ABB’s programmable logic controller that integrates seamlessly with PPD113B01-10-150000 3BHE023784R1023for centralized control in larger automation setups.

- PP865 3BSE042236R1: ABB’s 15-inch HMI panel that pairs with PPD113B01-10-150000 3BHE023784R1023to provide operators with visual monitoring of process data.

- CI854A 3BSE013232R1: ABB’s Profibus-DP communication module that can be used alongside PPD113B01-10-150000 3BHE023784R1023in systems requiring Profibus connectivity.

- PPD113B01-20-150000 3BHE023784R1024: Variant of PPD113B01-10-150000 3BHE023784R1023with enhanced surge protection, ideal for industrial environments with unstable power supplies.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing PPD113B01-10-150000 3BHE023784R1023, ensure the mounting rail is securely fastened to a stable surface capable of supporting the module’s weight. Use a torque wrench set to 0.5-0.8 Nm to attach the module to the DIN rail. Verify that the power supply is within the 18-30V DC range and that all wiring complies with local electrical codes. Prepare wire strippers (for 0.5-1.5mm² wires) and a multimeter for testing connections. Avoid installing PPD113B01-10-150000 3BHE023784R1023 near high-voltage equipment or sources of strong electromagnetic interference, such as motor starters, to prevent signal disruption.

Maintenance suggestions: Inspect PPD113B01-10-150000 3BHE023784R1023 quarterly for loose connections or dust accumulation—use compressed air (max 50 psi) to clean vents if necessary. Check digital and analog input/output signals annually using a signal generator to ensure accuracy within specified ranges. If communication issues arise, verify network settings and test with a known-good cable before replacing the module. For spare parts, use only ABB-approved components, such as the terminal block cover (part number 3BHE023784R0001), to maintain protection ratings and performance. Store replacement units in anti-static packaging in a dry environment (-40°C to 85°C) to preserve functionality.

Service and guarantee commitment

ABB stands behind PPD113B01-10-150000 3BHE023784R1023 with a 3-year warranty covering defects in materials and workmanship under normal operating conditions. Our global technical support team provides assistance 24/7, with response times within 8 hours for troubleshooting inquiries related to installation, configuration, or operation of PPD113B01-10-150000 3BHE023784R1023.

Factory-certified repair services ensure that any faulty units are restored to original specifications using genuine ABB components. For critical applications, we offer expedited replacement services with guaranteed delivery within 48 hours to minimize downtime. ABB also provides comprehensive training programs on PPD113B01-10-150000 3BHE023784R1023, helping customers maximize the module’s capabilities and ensure long-term reliability in their automation systems.