Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

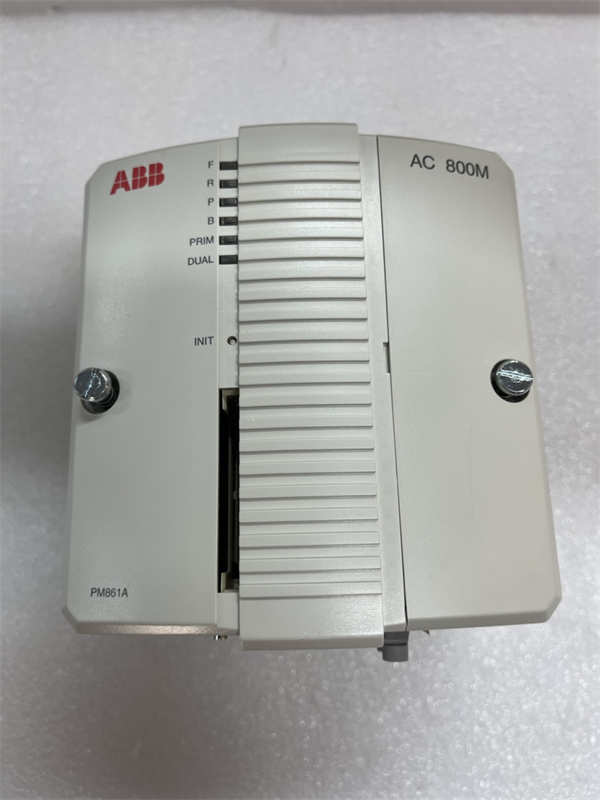

| Product Model | ABB PM861AK01 3BSE018157R1 |

| Manufacturer | ABB |

| Product Category | Process Automation Controller |

| Processor | Dual-core 1.2 GHz PowerPC |

| Memory | 1GB DDR3 RAM, 512MB Flash |

| Control Capacity | Up to 2000 I/O points |

| Communication Ports | 2x 10/100/1000 Ethernet, 1x RS-232/485 |

| Redundancy Support | Yes (with PM862) |

| Operating Temperature | 0°C to +60°C |

| Power Supply | 24V DC (±20%) |

| Power Consumption | 15W typical |

| Dimensions (W×H×D) | 45×130×115 mm |

| Certifications | CE, UL, IEC 61508 SIL2 |

ABB PM861AK01 3BSE018157R1

Product Introduction

The ABB PM861AK01 3BSE018157R1 represents the pinnacle of process automation control within ABB’s AC 800M controller family. This high-performance controller delivers real-time deterministic control for mission-critical industrial applications across power generation, oil & gas, and chemical processing industries. As part of ABB’s 800xA distributed control system, the PM861AK01 provides the processing power and reliability needed for complex automation tasks.

Engineered for 24/7 operation, the ABB PM861AK01 3BSE018157R1 combines a dual-core 1.2 GHz processor with 1GB RAM to execute advanced control algorithms while maintaining precise timing. Its modular design supports hot-swappable redundancy when paired with a PM862 controller, ensuring uninterrupted operation during maintenance or failures. The controller’s industrial-grade construction and wide operating temperature range make it suitable for installation in challenging plant environments.

Core Advantages and Technical Highlights

Processing power and performance:

The ABB PM861AK01 3BSE018157R1 delivers exceptional computing performance through its dual-core PowerPC architecture, capable of executing complex PID loops, sequence controls, and safety functions simultaneously. With 1GB DDR3 RAM, it handles large control strategies without performance degradation, while 512MB Flash memory ensures reliable program storage.

Reliable communication architecture:

Featuring dual Gigabit Ethernet ports, the controller provides redundant communication paths for critical networks. The integrated RS-232/485 serial port supports legacy device integration, while optional communication modules enable PROFIBUS DP/PA, Modbus TCP, and OPC UA connectivity. The deterministic execution engine guarantees precise timing for time-sensitive control applications.

Industrial durability:

Designed for harsh environments, the PM861AK01 operates reliably in 0°C to +60°C temperatures and withstands 2g vibration (10-150Hz). Its compact form factor (45×130×115 mm) saves panel space while maintaining excellent heat dissipation. The 24V DC power input with ±20% tolerance ensures stable operation during voltage fluctuations.

Advanced functionality:

The controller supports online modifications for uninterrupted process operation during programming changes. Its SIL2-certified architecture meets stringent safety requirements, while the hot-swappable design enables maintenance without system shutdown in redundant configurations. The embedded web server provides convenient access to diagnostic information and performance metrics.

Typical Application Scenarios

Power generation systems:

In combined-cycle power plants, the ABB PM861AK01 3BSE018157R1 controls turbine sequencing, manages fuel-air ratios, and monitors safety systems. Its deterministic performance ensures precise synchronization during generator startups, while redundant configuration guarantees continuous operation during maintenance periods.

Oil and gas processing:

The controller excels in offshore platform applications where it manages separator controls, compressor anti-surge systems, and safety shutdown functions. The PM861AK01‘s robust design withstands harsh marine environments while maintaining precise control of critical processes.

Chemical manufacturing:

For batch processes requiring exact timing and recipe management, the ABB PM861AK01 3BSE018157R1 provides the necessary computing power and reliability. Its ability to execute complex control strategies ensures consistent product quality while meeting stringent safety standards.

Water treatment facilities:

The controller manages distributed pumping stations, chemical dosing systems, and filtration processes across large treatment plants. Its communication capabilities enable seamless integration with SCADA systems while local processing reduces network latency.

ABB PM861AK01 3BSE018157R1

Related Model Recommendations

ABB PM862AK01: Enhanced version with additional communication options

ABB CI867: PROFINET communication interface module

ABB S800 I/O: High-density remote I/O system

ABB COM600: Protocol converter for network integration

ABB AC 800M: Base controller unit

ABB TP830: Operator panel for local control

ABB SAFE 800M: Safety controller for SIL3 applications

Installation and Commissioning

Installation preparation:

Before installing the ABB PM861AK01 3BSE018157R1, ensure the control cabinet meets environmental specifications with adequate ventilation and proper grounding. Verify the 24V DC power supply has sufficient capacity and protection. Prepare necessary tools including a T20 Torx driver for module mounting and a network cable tester.

Commissioning steps:

Mount the controller securely in the AC 800M rack

Connect power and verify LED status indicators

Configure network parameters using Control Builder

Load application software and verify functionality

Test redundancy failover (if applicable)

Document all configuration settings

Maintenance suggestions:

Regularly inspect the PM861AK01 for dust accumulation and clean ventilation openings annually. Monitor operating temperature through diagnostic tools and verify firmware is current during planned outages. Maintain backup copies of application programs and configuration files. In redundant systems, test failover functionality quarterly.

Service and Guarantee Commitment

ABB stands behind the PM861AK01 3BSE018157R1 with a comprehensive 3-year warranty covering manufacturing defects. Our global support network provides 24/7 technical assistance through ABB’s experienced automation specialists. Customers receive lifetime product support, including access to firmware updates and security patches throughout the product’s operational life.

The controller’s long-term availability guarantee (minimum 10 years) protects your investment, while ABB’s on-site service options ensure rapid resolution of critical issues. Comprehensive documentation including installation guides, application manuals, and certification files accompanies each unit, supported by ABB’s world-class training programs for engineers and technicians.