Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

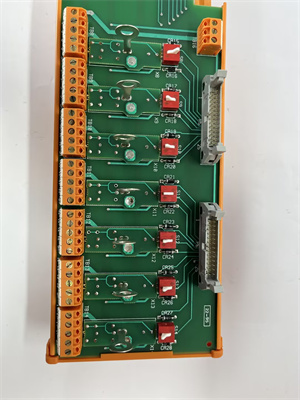

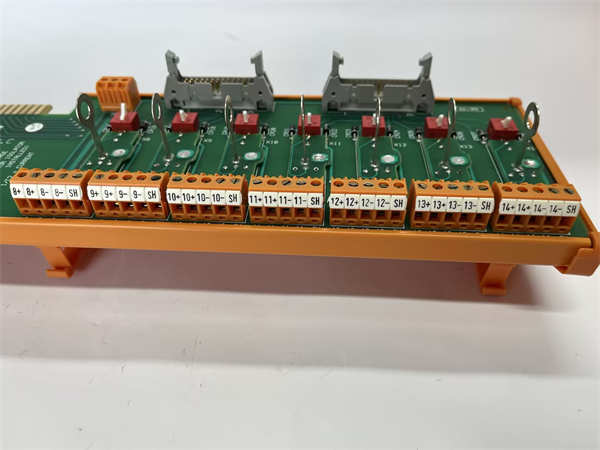

| Product model | ABB NRAO01 |

| Manufacturer | ABB |

| Product category | Remote Digital I/O Module |

| Operating Voltage | 24V DC ±10% |

| Operating Temperature Range | -20°C to +60°C |

| Dimensions (W x H x D) | 100 mm × 125 mm × 50 mm |

| Weight | 0.3 kg |

| Communication Interface | Profibus DP V1 (9.6 kbps–12 Mbps) |

| Certifications | CE, UL, IEC 61131-2 (safety), IEC 61000-6-2 (EMC) |

| Supported Protocols | Profibus DP, Ethernet/IP |

| Typical Power Consumption | 2W |

| Compatibility | ABB AC500, AC800M, and third-party PLCs |

ABB NRAO01

Product Introduction

The ABB NRAO01 is a compact and powerful remote I/O module designed for distributed control and monitoring in industrial automation systems. It serves as a vital link between field devices (sensors, actuators) and control systems, supporting real-time data exchange in harsh environments. The NRAO01 is optimized for remote monitoring and control in distributed systems, such as those found in manufacturing lines, energy plants, or water treatment facilities.

Core Advantages and Technical Highlights

High Reliability and Redundancy:

-

The ABB NRAO01 features dual-port Profibus connectivity for redundant communication, critical in high-availability systems. ABB’s remote I/O modules typically achieve MTBF > 150,000 hours, reducing unplanned downtime.

EMI Resistance:

-

Shielded housing and galvanic isolation protect against electromagnetic interference, a common issue in factory floors with heavy machinery.

Cost-Effective Expansion:

-

Aggregates 16 I/O points in a single module, cutting hardware costs by 20% compared to discrete wiring solutions.

User-Friendly Configuration:

-

Configurable via ABB’s Control Builder M software, with pre-defined templates for quick commissioning.

Rugged Design:

-

Built to withstand vibrations, EMI, and temperature ranges from -20°C to +60°C, ensuring operation in industrial settings.

Hot-Swap Capability:

-

Enables module replacement without system shutdown, reducing downtime by up to 40%.

ABB NRAO01

Typical Application Scenarios

The ABB NRAO01 is widely used across various industrial sectors:

-

Manufacturing: Controls conveyor belts, robotic arms, and safety interlocks in automotive or food processing plants.

-

Energy: Monitors pump status and valve positions in wastewater treatment or renewable energy installations.

-

Infrastructure: Manages access controls and lighting in smart buildings or transportation hubs.

Related Model Recommendations

-

ABB AIA810: For analog signal handling, consider this module for applications requiring analog inputs.

-

ABB CI858K01: For Ethernet communication, explore this module if your system requires Ethernet/IP.

-

ABB UDC810: For large-scale distributed setups, pair with this power supply module.

Installation, Commissioning, and Maintenance Instructions

Installation:

-

Power down the bus before connecting/disconnecting the NRAO01 to avoid ESD damage.

-

Use shielded Profibus cables and ground them properly to minimize EMI.

Configuration:

-

Assign unique addresses via the module’s DIP switches or software to prevent address conflicts.

-

Test signal logic (e.g., NO/NC for inputs) during commissioning.

Maintenance:

-

Inspect DIN rail mounts annually for looseness; tighten if necessary.

-

Replace modules every 7–10 years to maintain warranty compliance.

Service and Guarantee Commitment

ABB provides comprehensive support for the ABB NRAO01, including a robust warranty that ensures product quality and reliability. The company offers extensive after-sales services such as technical support, repair services, and spare part supply. ABB’s global network of service centers ensures prompt assistance and expert guidance, demonstrating the company’s commitment to customer satisfaction and product excellence.