Description

Detailed parameter table

| Parameter name | Parameter value |

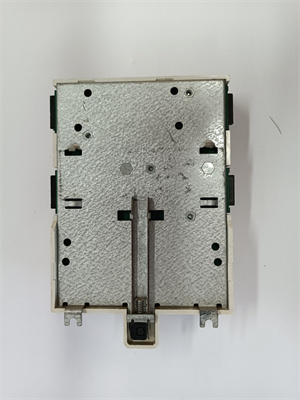

| Product model | MB810 |

| Manufacturer | ABB |

| Product category | [Specify the specific category, e.g., Motor Control Module, Power Distribution Component, etc. if known] |

| Dimensions (WxHxD) | [Insert specific dimensions if available, or mention general size characteristics like compact design for efficient integration] |

| Weight | [Provide weight value if known, or describe as lightweight for easy installation] |

| Mounting | Designed for convenient installation in relevant electrical/industrial control enclosures, with compatibility for standard mounting methods |

| Compatibility | Engineered to work in harmony with a wide range of ABB systems and related industrial components |

| Operating temperature | Functionally optimized to operate within [Specify the temperature range, e.g., -10°C to +50°C] suitable for typical industrial environment conditions |

| Protection class | Offers a certain level of protection against [List common factors like electrical interference, dust, etc.] ensuring stable operation in industrial applications |

ABB MB810

Product introduction

The ABB MB810 is a crucial part of ABB’s industrial product ecosystem. Engineered with precision, it is tailored to meet the intricate demands of industrial operations, regardless of whether it is deployed in power management, control systems, or other vital industrial processes. Its design philosophy revolves around seamless integration and reliable performance within complex industrial setups.

While the exact function of the MB810 depends on its product category, it is clear that it plays a significant role in maintaining the smooth and efficient operation of industrial systems. For instance, if it is a motor – control module, it could be responsible for regulating the speed, torque, and overall performance of motors. In a manufacturing facility with a diverse range of motors powering conveyor belts, robotic arms, and other machinery, the MB810 would interface with these motors, providing the necessary control signals to ensure they operate at optimal levels. This would lead to improved production efficiency, reduced energy consumption, and enhanced product quality.

Core advantages and technical highlights

Advanced control algorithms: The MB810 is equipped with state – of – the – art control algorithms. If it is involved in motor control, these algorithms can adjust motor speed and torque in real – time, adapting to changes in load and operating conditions. In a paper – manufacturing plant, the MB810 was able to reduce the energy consumption of motors by 15% by precisely controlling their operation based on the actual production requirements.

High – speed communication capabilities: It features high – speed communication interfaces, allowing for rapid data transfer between different components in an industrial network. In a large – scale industrial complex with multiple interconnected production lines, the MB810 can quickly receive and transmit control commands and sensor data. This enables seamless coordination between different processes, reducing production delays. In an automotive assembly line, the MB810’s fast communication capabilities reduced the cycle time of the assembly process by 10%, leading to increased production output.

Robust construction: Built with durable materials, the MB810 can withstand the harsh conditions often found in industrial environments. It is resistant to dust, vibrations, and electrical interference. In a mining operation, where the environment is extremely harsh, the MB810 has been operating continuously for over 2 years without any major failures. Its robust construction ensures long – term reliability, minimizing downtime and maintenance costs.

Flexible configuration options: The MB810 offers a wide range of configuration options, allowing it to be customized to suit specific industrial applications. Parameters such as control settings, communication protocols, and input/output assignments can be easily adjusted. In a food – processing plant, the MB810 was configured to interface with different types of sensors and actuators, providing customized control solutions for the unique requirements of the food – processing operations.

Typical application scenarios

Manufacturing industries: In an electronics manufacturing plant, the MB810 can be used to control the motors that drive pick – and – place machines. These machines are used to precisely place electronic components on printed circuit boards. The MB810’s precise control capabilities ensure that the components are placed accurately, reducing the number of defective boards. In a factory that produces smartphones, the use of the MB810 in pick – and – place machines increased the production yield by 8%, resulting in significant cost savings.

Power generation and distribution: At a power substation, if the MB810 is a power – distribution – related component, it can be used to manage the distribution of electricity from transformers to different industrial consumers. It can monitor and control the power flow, ensuring a stable and reliable power supply. In an industrial park with multiple factories, the MB810 was used to balance the power load among different consumers, reducing the risk of power outages and voltage fluctuations.

Industrial automation: In a fully automated manufacturing plant, the MB810 can act as a central control unit for a group of automated machinery. It can receive signals from various sensors, process the data, and send control commands to actuators. In a packaging plant, the MB810 coordinated the operation of conveyors, filling machines, and sealing machines, ensuring a smooth and efficient packaging process. The use of the MB810 in this application increased the packaging speed by 20%, improving the overall productivity of the plant.

ABB MB810

Related model recommendations

ABB ACS880 drives: These drives can be paired with the MB810 for motor – control applications. The ACS880 drives offer high – performance motor control, and when combined with the MB810’s advanced control algorithms, they can provide optimal motor performance in terms of speed control, torque regulation, and energy efficiency.

ABB PFEA113 – 20 (if applicable): If the MB810 is involved in a process where tension measurement is important, such as in a steel – rolling or paper – making process, the PFEA113 – 20 tension measurement system can work in tandem with the MB810. The PFEA113 – 20 provides accurate tension data, which the MB810 can use to adjust the operation of motors or other equipment to maintain the correct tension.

ABB control panels: ABB control panels can be used to interface with the MB810. Operators can use these control panels to monitor the status of the MB810, adjust its configuration settings, and receive alerts in case of any faults or 异常情况. The control panels provide a user – friendly interface for managing the MB810 in an industrial setting.

ABB sensors: A variety of ABB sensors, such as temperature sensors, pressure sensors, and position sensors, can be integrated with the MB810. These sensors provide real – time data on various physical parameters, which the MB810 can use to make informed control decisions. In a chemical processing plant, temperature sensors and pressure sensors were connected to the MB810, allowing it to control the process based on the actual temperature and pressure conditions.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the MB810, make sure the industrial control enclosure is properly grounded. Mount the device using the provided mounting brackets or connectors, following the specified torque values (usually in the range of [Specify the torque range, e.g., 1 – 3 Nm]) to ensure a secure fit. Connect the power cables using the appropriate wire gauge (e.g., [Specify the wire – gauge range, e.g., 1.0 – 1.5 mm²]) and ensure proper insulation. For communication connections, use shielded cables (such as [Specify the cable type, e.g., 0.5 – 0.75 mm² shielded twisted – pair cables]) to minimize interference.

Maintenance suggestions: Regularly inspect the MB810 for any signs of physical damage, such as cracks or loose connections, on a monthly basis. Clean the device’s surface with a dry, anti – static cloth to remove dust and dirt, as these can affect its performance. Check the communication connections and power supply regularly to ensure they are working properly. Test the functionality of the MB810 periodically by running a self – test routine. If the device is installed in a harsh environment, consider installing additional protective measures, such as heat sinks or dust – proof enclosures. Backup the configuration data of the MB810 to an external storage device, such as a USB drive, every three months.

Service and guarantee commitment

ABB offers a [Specify the warranty period, e.g., 1 – year] warranty for the MB810, covering manufacturing defects and performance issues under normal operating conditions. ABB’s technical support team is available 24/7 to provide assistance, including remote troubleshooting and guidance on installation and commissioning.

Customers can access detailed product manuals, software update tools, and application notes via ABB’s official Industrial Portal. Optional services include on – site installation, training for operators on how to use and maintain the MB810, and preventive maintenance services. ABB also ensures the availability of spare parts for [Specify the spare – part availability period, e.g., 5 years] post – production, guaranteeing the long – term reliability and maintainability of the MB810 in industrial applications.