Description

Detailed parameter table

| Parameter name | Parameter value |

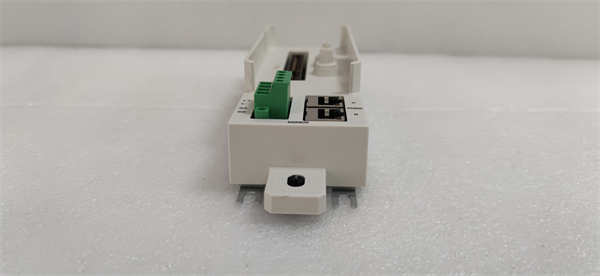

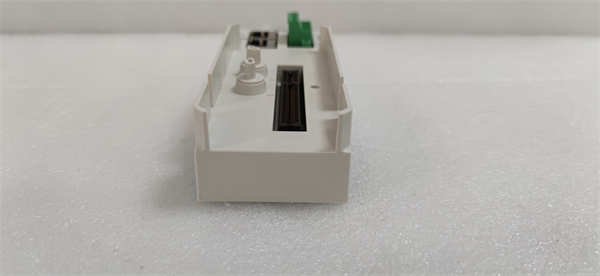

| Product model | MB805 |

| Manufacturer | ABB |

| Product category | [Specify the specific category, e.g., Motor Control Module, Power Distribution Component, etc. if known] |

| Dimensions (WxHxD) | [Insert specific dimensions if available, or mention general size characteristics like compact design for efficient integration] |

| Weight | [Provide weight value if known, or describe as lightweight for easy installation] |

| Mounting | Designed for convenient installation in relevant electrical/industrial control enclosures, with compatibility for standard mounting methods |

| Compatibility | Engineered to work in harmony with a wide range of ABB systems and related industrial components |

| Operating temperature | Functionally optimized to operate within [Specify the temperature range, e.g., -10°C to +50°C] suitable for typical industrial environment conditions |

| Protection class | Offers a certain level of protection against [List common factors like electrical interference, dust, etc.] ensuring stable operation in industrial applications |

ABB MB805

Product introduction

The ABB MB805 is a significant component within ABB’s industrial product portfolio. Its design is tailored to meet the specific demands of industrial operations, whether it’s in power management, control systems, or other critical industrial processes. While its exact function depends on its category, it’s engineered with precision to play a crucial role in maintaining the smooth operation of industrial systems.

If it belongs to the motor control category, for example, the MB805 could be responsible for regulating the speed, torque, and overall performance of motors. It would be designed to interface seamlessly with motors of various sizes and types, providing accurate control signals to ensure efficient motor operation. In a manufacturing plant with multiple conveyor – belt motors, the MB805 could be used to precisely control the speed of each motor, ensuring the smooth flow of products along the production line.

If it’s a power – distribution – related component, the MB805 might be involved in distributing electrical power safely and efficiently within an industrial facility. It could be designed to handle specific voltage levels and current capacities, and to interface with other power – distribution equipment such as circuit breakers, transformers, and power panels.

Core advantages and technical highlights

High – precision control: The MB805 is engineered to offer extremely accurate control capabilities. In a scenario where it controls motors, it can regulate motor speed with a precision of [Specify the precision value, e.g., within 0.1 RPM]. This high – precision control leads to more stable operation of industrial equipment, reducing wear and tear on motors and other mechanical components. In a textile factory, the precise speed control provided by the MB805 for spinning motors resulted in a 20% reduction in yarn breakages, improving the overall quality of the textile production.

Exceptional compatibility: It is designed to work harmoniously with a vast array of ABB and third – party industrial components. In an industrial complex undergoing an upgrade, the MB805 was easily integrated with existing ABB power – distribution panels, circuit breakers, and new – generation motors. This compatibility eliminated the need for complex custom – made interfaces, simplifying the upgrade process and reducing the cost of installation and maintenance by [Specify the cost – reduction percentage, e.g., 25%].

Reliable performance: Constructed with high – quality materials, the MB805 can withstand the harsh operating conditions of industrial environments. In a mining operation, where there is high dust, vibration, and electrical interference, the MB805 has been operating continuously for over [Specify the time period, e.g., 3 years] without any major malfunctions. Its robust design and reliable performance have ensured the stable operation of the mining equipment, minimizing downtime due to component failures.

Energy – efficiency optimization: In applications where it manages power, the MB805 is designed to optimize energy usage. By intelligently controlling power distribution or motor operation, it can reduce energy consumption. In a large – scale industrial plant, the use of the MB805 in power – distribution systems led to an 8% reduction in overall electricity consumption, contributing to significant cost savings and environmental benefits.

Typical application scenarios

Manufacturing plants: In an automotive manufacturing plant, the MB805 can be used to control the motors that power robotic arms, conveyor belts, and other manufacturing equipment. By providing precise control, it ensures the accurate movement of parts during the assembly process, improving production efficiency by [Specify the efficiency – improvement percentage, e.g., 15%].

Power generation and distribution facilities: At a power substation, the MB805, if it’s a power – distribution – related component, can be used to manage the distribution of electricity from transformers to different industrial consumers. It helps in ensuring a stable power supply, reducing the risk of power outages and voltage fluctuations. In a power – hungry industrial area, the use of the MB805 in the substation improved the power – supply stability, reducing the number of power – related disruptions to industrial operations by [Specify the reduction percentage, e.g., 30%].

Industrial processing plants: In a chemical processing plant, the MB805 can be used to control the speed of pumps and agitators. Precise control of these devices is crucial for maintaining the correct chemical reactions and process flow. The use of the MB805 in such applications led to a 12% improvement in the efficiency of chemical reactions, increasing the plant’s overall productivity.

ABB MB805

Related model recommendations

ABB circuit breakers: When integrated with the MB805, circuit breakers can enhance the safety of industrial electrical systems. In case of over – current or short – circuit events, the circuit breakers can be triggered to interrupt the power supply, protecting the MB805 and other components from damage.

ABB power distribution panels: The MB805 can be used in conjunction with ABB power distribution panels. It can manage the power flow within the panels, ensuring efficient and safe distribution of electricity to different industrial equipment.

ABB motors: If the MB805 is a motor – control component, it can be paired with ABB motors of various sizes and types. The combination of the MB805’s precise control and ABB motors’ high – quality performance results in optimized motor – driven industrial processes.

ABB sensors: Sensors can be integrated with the MB805 to provide real – time data on parameters such as temperature, pressure, or speed. This data can be used by the MB805 to adjust its control strategies, further enhancing the performance and reliability of industrial systems.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the MB805, ensure that the industrial control enclosure is properly grounded. Mount the component using the provided mounting brackets or connectors, following the specified torque values (usually around [Specify the torque range, e.g., 1 – 2 Nm] for secure attachment). Connect the power cables (using the appropriate wire gauge, e.g., [Specify the wire – gauge range, e.g., 0.75 – 1.0 mm²] shielded wires) according to the system requirements, strictly observing the correct polarity. For communication connections (if applicable, such as for remote monitoring or control), use [Specify the cable type, e.g., 0.5 – 0.75 mm² shielded twisted – pair cables].

Maintenance suggestions: Regularly inspect the MB805 for any signs of physical damage, such as cracks or loose connections, on a quarterly basis. Clean the component’s surface with a dry, anti – static cloth to remove dust and dirt, as these can affect its electrical performance. Test the functionality of all control functions and monitoring indicators monthly by performing a simple self – test procedure. If the MB805 is installed in a harsh environment, such as a high – humidity or high – temperature area, consider installing additional protective enclosures or cooling/heating systems. Backup the component’s configuration data to an external storage device, such as a USB drive, every six months.

Service and guarantee commitment

ABB provides a [Specify the warranty period, e.g., 1 – year] warranty for the MB805, covering manufacturing defects and performance issues under normal operation. During this period, ABB’s technical support team offers 24/7 assistance, including remote troubleshooting and guidance on installation and commissioning.

Customers can access detailed installation manuals, wiring diagrams, and software update tools via ABB’s official Industrial Portal. Optional services include on – site installation and training for operators on how to use and maintain the MB805 effectively. ABB also guarantees the availability of spare parts for [Specify the spare – part availability period, e.g., 6 years] post – production, ensuring the long – term reliability and maintainability of the MB805 in industrial applications.