Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

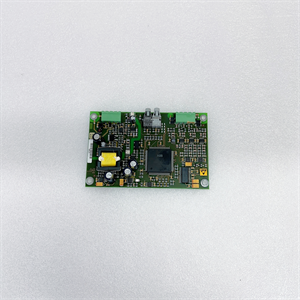

| Product model | ABB LDSYN-101 3BHE005555R0101 |

| Manufacturer | ABB |

| Product category | Data Synchronization Module |

| Operating Voltage | 220V AC |

| Frequency Range | 50/60 Hz |

| Communication Interface | Ethernet, PROFIBUS DP, Modbus TCP |

| Operating Temperature Range | -20°C to +70°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity | 5% to 95% (non-condensing) |

| Dimensions | 150 mm x 100 mm x 50 mm |

| Weight | 1.2 kg |

| Certifications | CE, RoHS |

| Supported Protocols | Ethernet/IP, Profinet, Modbus RTU, OPC UA |

LDSYN-101 3BHE005555R0101

Product Introduction

The ABB LDSYN-101 3BHE005555R0101 is a high-performance data synchronization module designed for industrial automation systems. It serves as a central hub for synchronizing data between multiple control platforms, including ABB’s own distributed control systems (DCS) and programmable logic controllers (PLCs), as well as third-party devices that support common industrial communication protocols. This module is equipped with a high-speed processing unit capable of handling large amounts of data traffic with extremely low latency, ensuring real-time data synchronization and precise control.

Core Advantages and Technical Highlights

High-Speed Data Synchronization: The ABB LDSYN-101 3BHE005555R0101 processes data with minimal latency, enabling real-time decision-making and precise control in industrial processes.

Redundant Communication Paths: The module supports redundant communication paths to enhance system reliability. In the event of a main link failure, backup paths automatically activate to maintain data synchronization.

Wide Protocol Compatibility: Supporting multiple industrial protocols such as Ethernet/IP, Profinet, Modbus RTU, and OPC UA, the ABB LDSYN-101 3BHE005555R0101 simplifies integration with various devices and systems.

Robust Industrial Design: With an operating temperature range of -20°C to +70°C and a storage temperature range of -40°C to +85°C, the module is designed to withstand harsh industrial environments.

Advanced Diagnostics: Built-in diagnostic functions continuously monitor synchronization status, providing immediate alerts for any discrepancies or issues, which facilitates rapid troubleshooting and resolution.

LDSYN-101 3BHE005555R0101

Typical Application Scenarios

The ABB LDSYN-101 3BHE005555R0101 is widely used across various industries:

-

Food and Beverage: Ensures synchronized operation of production equipment, optimizing production speed and maintaining product consistency.

-

Chemical Processing: Enables real-time monitoring and control of multiple chemical reactions and processes, preventing potential safety hazards.

-

Smart Grid: Synchronizes data from numerous sensors, meters, and control devices in the electrical network, improving grid stability and reliability.

-

Logistics and Warehousing: Coordinates the operation of automated guided vehicles (AGVs), conveyor systems, and inventory management systems for seamless material handling.

Related Model Recommendations

-

ABB LDSYN-201 3BHE005556R0101: Offers enhanced processing power and higher data throughput, suitable for data-intensive applications.

-

ABB LDSYN-102 3BHE005557R0101: Provides additional communication interfaces for greater network integration flexibility.

-

ABB LDSYN-301 3BHE005558R0101: Designed for ultra-high-speed data synchronization in advanced manufacturing environments.

-

ABB LDSYN-103 3BHE005559R0101: An affordable alternative with basic data synchronization capabilities, suitable for small projects.

-

ABB LDSYN-202 3BHE005560R0101: Includes advanced diagnostic capabilities for deeper system monitoring and predictive maintenance.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation:

-

Ensure the control system and existing equipment are compatible with the module’s communication protocols.

-

Verify that the network infrastructure can support the module’s data traffic requirements.

-

Follow recommended guidelines for proper ventilation and accessibility during installation.

Maintenance Suggestions:

-

Regularly monitor the module’s diagnostic indicator lights to detect any signs of abnormal operation or synchronization issues.

-

Clean the communication interfaces periodically to prevent dust and debris from affecting signal quality.

-

Update the module’s firmware to the latest version provided by ABB for performance improvements and security patches.

-

Perform routine system checks to verify the integrity of redundant communication paths and conduct comprehensive testing annually.

Service and Guarantee Commitment

ABB provides comprehensive support for the ABB LDSYN-101 3BHE005555R0101, including a robust warranty that ensures product quality and reliability. The company offers extensive after-sales services such as technical support, repair services, and spare part supply. ABB’s global network of service centers ensures prompt assistance and expert guidance, demonstrating the company’s commitment to customer satisfaction and product excellence.