Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB HC800 |

| Manufacturer | ABB |

| Product category | High-Performance Control Processor Module |

| Input voltage range | 24V DC ±10% |

| Output voltage | 3.3V |

| Operating temperature | -40°C to +85°C |

| Storage temperature | -40°C to +85°C |

| Humidity | 5% to 95% non-condensing |

| Protection class | IP20 |

| Dimensions | 78.74 mm (D) x 243.84 mm (H) x 210.82 mm (W) |

| Weight | 0.88 kg |

| Processor | 1 GHz dual-core processor |

| Memory | 1 GB DDR3 RAM, 4 GB eMMC flash memory |

| Communication protocols | Modbus TCP/IP, Profibus, Ethernet (10/100/1000 Mbps) |

| Certifications | CE, UL, IEC 61000-4 series |

| Function blocks supported | Up to 30,000 function blocks |

| Power consumption | 10 W typical |

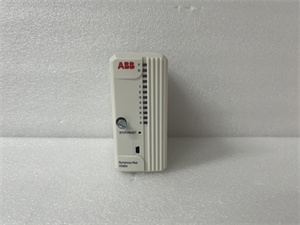

ABB HC800

Product Introduction

The ABB HC800 is a high-performance control processor module designed for industrial automation and control systems. It is part of ABB’s HPC800 series and is engineered to meet the demands of complex industrial environments. The HC800 offers advanced control capabilities, supporting up to 30,000 function blocks and multiple communication protocols, making it highly scalable and adaptable to evolving needs.

Core Advantages and Technical Highlights

High Performance: The HC800 is equipped with a 1 GHz dual-core processor and 1 GB DDR3 RAM, ensuring fast and efficient data processing for real-time operations.

Reliability: The module features a mean time between failures (MTBF) exceeding 100,000 hours, ensuring long-term stable operation in harsh industrial conditions.

Modular Design: The HC800 supports a modular architecture, allowing for flexible configuration and expansion to meet specific application requirements.

Communication Capabilities: The module supports multiple communication protocols, including Modbus TCP/IP, Profibus, and Ethernet, facilitating seamless integration with existing industrial networks.

Scalability: The HC800 can handle over 5,000 I/O points in closed-loop operations in less than 250 milliseconds and supports scaling up to 2,048 I/O points.

Advanced Diagnostics: The module includes advanced diagnostic features for monitoring system health and detecting potential faults, helping to reduce downtime and improve system reliability.

ABB HC800

Typical Application Scenarios

The ABB HC800 is widely used in various industrial sectors, including:

-

Manufacturing: Controlling production lines and robotic systems.

-

Power Generation: Managing turbines, generators, and boilers in power plants.

-

Oil & Gas: Controlling pipeline monitoring and refinery operations.

-

Water Treatment: Regulating water flow and treatment processes.

-

Process Control: In industries such as chemical, pharmaceutical, and petrochemical, for real-time monitoring and control of process parameters.

Related Model Recommendations

-

ABB AC800M: A modular PLC system that the HC800 is compatible with for enhanced control solutions.

-

ABB Symphony Plus: A comprehensive DCS system that the HC800 integrates with for advanced control applications.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the ABB HC800, ensure that the environment meets the specified requirements, including an operating temperature range of -40°C to +85°C. The installation location should be free from excessive dust, moisture, and corrosive gases to ensure long-term reliability. Use a standard DIN rail for secure installation.

Maintenance Suggestions

To maintain the ABB HC800, perform regular inspections of the module and its connections to ensure they are secure and free from corrosion. Clean the unit regularly with a soft, dry cloth to remove dust and debris. If any issues arise, refer to the troubleshooting guide in the user manual for common solutions. Replace any worn or damaged parts promptly to ensure continued performance.