Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

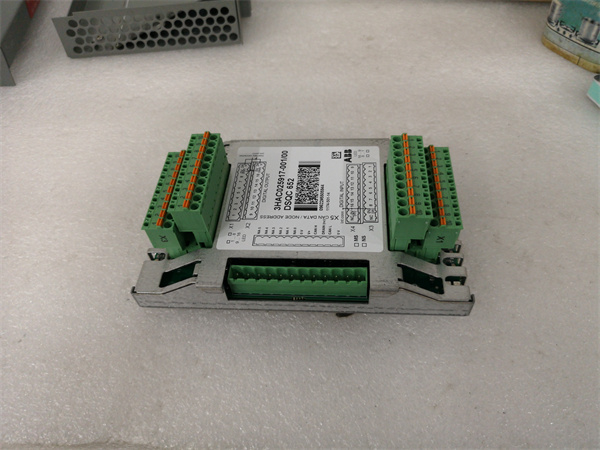

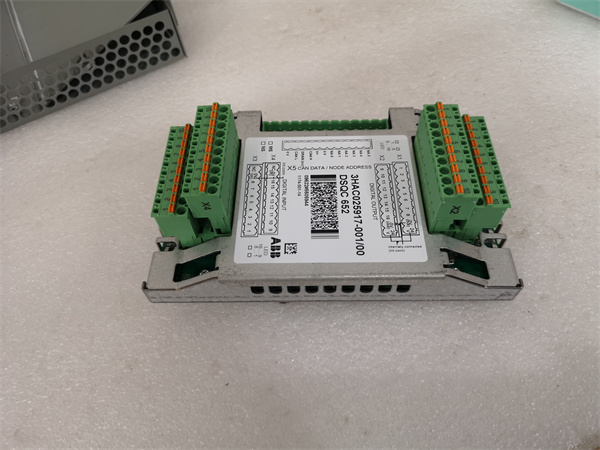

| Product Model | DSQC652 |

| Manufacturer | ABB |

| Product Category | Digital I/O Module |

| Input Channels | 16 digital inputs |

| Output Channels | 16 digital outputs |

| Communication Protocol | DeviceNet |

| Operating Voltage | 24V DC |

| Operating Temperature Range | -25°C to +55°C |

| Dimensions (L x W x H) | 120 mm x 85 mm x 40 mm |

| Weight | 0.5 kg |

| Protection Rating | IP20 |

| Certifications | CE, UL |

ABB DSQC652

Product Introduction

The ABB DSQC652 is a high-performance digital I/O module designed for use with ABB robots and industrial automation systems. It provides 16 digital input and 16 digital output channels, making it ideal for controlling and monitoring various robotic and automation applications. The module supports DeviceNet communication protocol, ensuring seamless integration with ABB’s robot controllers and other industrial devices.

Core Advantages and Technical Highlights

Robust Communication: The DSQC652 supports DeviceNet protocol, enabling reliable and efficient communication with ABB robot controllers and other industrial devices. This protocol ensures fast and accurate data transfer, crucial for real-time control and monitoring.

High-Density I/O: With 16 digital inputs and 16 digital outputs, the DSQC652 offers a high-density I/O solution, reducing the need for additional hardware and simplifying system design. This makes it ideal for applications requiring extensive digital control and monitoring.

Easy Configuration: The module can be easily configured using ABB’s RobotStudio software or the robot’s teach pendant. Users can set up the I/O addresses, signal names, and other parameters through a user-friendly interface.

Reliable Performance: The DSQC652 is designed to operate reliably in harsh industrial environments, with an operating temperature range of -25°C to +55°C. Its compact form factor and lightweight design make it easy to install in space-constrained control cabinets.

Address Setting: The module’s address is set using a jumper configuration, allowing for easy identification and communication within a DeviceNet network. This feature ensures that each module can be uniquely identified and controlled.

ABB DSQC652

Typical Application Scenarios

The ABB DSQC652 is widely used in various industrial sectors, particularly in robotics and automation. In automotive manufacturing, it controls welding robots, ensuring precise and consistent operations. In electronics manufacturing, the module monitors and controls assembly line robots, improving production efficiency and quality. It is also used in general industrial automation for controlling conveyors, actuators, and other machinery.

Related Model Recommendations

-

DSQC355A: An upgraded version with enhanced features and improved performance, offering a future-proof solution for advanced digital signal processing needs.

-

DSQC655: A complementary module with additional I/O capabilities, suitable for applications requiring more extensive control and monitoring.

-

DSQC377A: A module designed for specific robot control applications, providing specialized I/O and communication features.

-

DSQC378A: A module with enhanced functionality for complex automation tasks, offering additional I/O points and advanced control capabilities.

-

DSQC662: A related module with similar functionality, suitable for applications requiring a different form factor or additional features.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation: Before installing the ABB DSQC652, ensure the designated location meets the specified temperature and humidity requirements. Mount the module securely on a standard DIN rail or panel using the provided hardware. Use shielded cables for connections to minimize electrical interference. Ensure proper grounding and power supply specifications to prevent voltage fluctuations.

Maintenance Suggestions: Perform regular visual inspections to check for dust accumulation, wear, or damage. Clean ventilation openings to ensure proper airflow and prevent overheating. Monitor diagnostic indicators for any abnormal conditions or warning messages. In harsh environments, consider implementing a scheduled maintenance program to minimize downtime.

Service and Guarantee Commitment

The ABB DSQC652 is backed by ABB’s comprehensive support and quality assurance. The module comes with a warranty that ensures protection against manufacturing defects. ABB’s global technical support network offers 24/7 assistance with guaranteed response times, ensuring minimal downtime and maximum efficiency. Each DSQC652 undergoes extensive testing to ensure reliability in industrial environments, providing customers with confidence in the product’s long-term performance.