Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

| Product model | ABB AO910 |

| Manufacturer | ABB |

| Product category | Analog Output Module |

| Output Channels | 8 channels |

| Signal Types | 0-10 V, 0-20 mA, 4-20 mA |

| Resolution | 12-bit |

| Load Resistance | Max 750 Ω (short-circuit-proof) |

| Isolation | 500 V (channel to bus) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 5% to 95% RH (non-condensing) |

| Protection Rating | IP20 |

| Dimensions | 120 mm (W) x 100 mm (H) x 40 mm (D) |

| Weight | 0.2 kg |

| Communication | Modbus RTU, HART protocol |

| Power Supply | 24V DC |

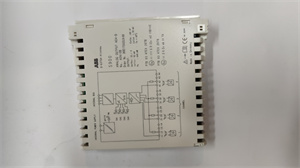

ABB AO910

Product Introduction

The ABB AO910 is a high-precision analog output module designed for industrial automation applications. It features 8 output channels that can be configured for 0-10 V, 0-20 mA, or 4-20 mA signals, providing high-resolution and precise control for various applications. The module supports Modbus RTU and HART protocol, ensuring seamless integration with existing automation systems.

Core Advantages and Technical Highlights

High Precision and Reliability: The ABB AO910 offers high-precision analog output with a 12-bit resolution, ensuring accurate signal transmission. It supports short-circuit protection and intra-group isolation, enhancing system reliability.

Advanced Communication: The module supports Modbus RTU and HART protocol, facilitating seamless integration into existing automation systems. It can be easily configured and monitored using ABB’s dedicated software.

Robust Design: The AO910 is designed to operate reliably within a wide temperature range of -20°C to +60°C and offers IP20 protection against dust and non-condensing moisture.

Self-Diagnostics: The module performs self-diagnostic checks cyclically, ensuring continuous monitoring of its operational status and providing early detection of potential issues.

Flexible Configuration: Each channel can be independently configured for different signal types and ranges, providing flexibility for various industrial applications.

ABB AO910

Typical Application Scenarios

The ABB AO910 is widely used in industries where precise control and monitoring are essential. In manufacturing plants, it controls actuators and valves, ensuring efficient process control. In power generation facilities, the AO910 monitors and controls equipment, optimizing performance and reliability. It is also used in water treatment plants to control pumps and valves, ensuring optimal water management.

Related Model Recommendations

-

ABB AC800M: A powerful PLC controller that integrates seamlessly with the ABB AO910 for advanced automation control.

-

ABB AI810: A complementary analog input module for precise data acquisition.

-

ABB DI810: A digital input module that can be used alongside the ABB AO910 to provide a complete I/O solution.

-

ABB AC500: A versatile PLC platform that can be used in conjunction with the ABB AO910 for comprehensive control systems.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the ABB AO910, ensure the environment meets the specified temperature and humidity requirements (-20°C to +60°C, 5% to 95% RH non-condensing). Use shielded cables and proper grounding to minimize electromagnetic interference. Follow ABB’s guidelines for DIN rail mounting, ensuring proper ventilation and protection from dust.

Maintenance Suggestions: Regularly inspect connections for wear and clean the module with a static-free cloth to ensure optimal heat dissipation. Use ABB’s dedicated software for module configuration and firmware updates. Follow ABB’s guidelines for handling sensitive components, including anti-static measures during maintenance.

Service and Guarantee Commitment

ABB stands behind the quality and reliability of the ABB AO910, offering a comprehensive warranty that covers manufacturing defects and performance issues for a specified period. Our dedicated after-sales support team is available to assist with technical inquiries and provide prompt solutions to ensure minimal disruption to your operations. We also offer extensive training and technical support services to help customers fully leverage the capabilities of the module, ensuring optimal performance and efficiency in their industrial applications.