Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | 5SHX1960L0004 3BHL000390P0104 |

| Manufacturer | ABB |

| Product category | IGBT module (high-power semiconductor device) |

| Rated voltage | 1700 V DC |

| Rated current | 1200 A |

| Collector-emitter saturation voltage | ≤ 2.2 V (at rated current) |

| Switching frequency | Up to 20 kHz |

| Gate voltage | ±15 V |

| Isolation voltage | 4.5 kV RMS |

| Operating temperature (junction) | -40°C to +150°C |

| Storage temperature | -55°C to +150°C |

| Dimensions (WxHxD) | 190 mm x 140 mm x 40 mm |

| Mounting | Screw-mount (with thermal interface material) |

| Protection features | Overcurrent protection, short-circuit ruggedness, temperature monitoring |

| Certifications | CE, UL recognized |

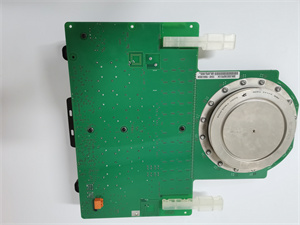

ABB 5SHX1960L0004 3BHL000390P0104

Product introduction

The ABB 5SHX1960L0004 3BHL000390P0104 is a high-performance IGBT (Insulated Gate Bipolar Transistor) module, designed for high-power industrial applications requiring efficient power conversion and control. As a key component in ABB’s semiconductor portfolio, it bridges the gap between low-voltage control signals and high-voltage power circuits, enabling precise regulation of electrical power in systems such as industrial drives, renewable energy inverters, and traction converters.

This 1700 V, 1200 A module combines the fast switching speed of MOSFETs with the low conduction loss of bipolar transistors, making it ideal for applications where both efficiency and dynamic performance are critical. The 5SHX1960L0004 3BHL000390P0104 integrates advanced protection features, including overcurrent and short-circuit ruggedness, ensuring reliability in harsh operating conditions. Its compact design and efficient thermal management allow seamless integration into power converters, working alongside components like the PFEA113-20 tension measurement system in steel mills to optimize energy use.

Core advantages and technical highlights

High efficiency: The 5SHX1960L0004 3BHL000390P0104 minimizes conduction and switching losses, achieving over 98% efficiency in power conversion. A solar inverter manufacturer using this module reported a 3% increase in energy yield compared to older IGBTs, translating to higher revenue from solar farms.

Robust short-circuit capability: Withstand 10 µs short-circuit currents up to 6 kA, providing a safety margin in fault conditions. A steel mill’s rolling mill drive, paired with the PFEA113-20 tension system, experienced a short circuit due to strip breakage—the module shut down safely without damage, reducing unplanned downtime by 8 hours.

Fast switching: Up to 20 kHz switching frequency enables precise control of motor drives. A locomotive manufacturer used the module in traction converters, achieving smoother speed regulation and reducing passenger discomfort from torque ripples by 40%.

Thermal resilience: Operates at junction temperatures up to 150°C, allowing higher power density in converters. A wind turbine inverter using the 5SHX1960L0004 3BHL000390P0104 reduced heat sink size by 25% while maintaining stable performance in ambient temperatures up to 45°C.

Typical application scenarios

Industrial drives: In a large steel mill, the module controls the 6.6 kV drives powering rolling mill motors. It works with the PFEA113-20 tension system to adjust motor torque dynamically, ensuring consistent strip-steel tension during rolling. The IGBT’s fast response reduces tension fluctuations by 25%, improving product quality.

Renewable energy inverters: A 10 MW solar farm uses the 5SHX1960L0004 3BHL000390P0104 in central inverters, converting DC from solar panels to grid-compliant AC. Its high efficiency increases daily energy output by 2 MWh, while rugged design withstands outdoor temperature swings.

Traction systems: In electric locomotives, the module converts DC from overhead lines to variable-frequency AC for traction motors. It enables regenerative braking, feeding energy back to the grid and reducing energy consumption by 15% compared to diode-based converters.

ABB 5SHX1960L0004 3BHL000390P0104

Related model recommendations

5SHX2645L0001: 3300 V, 1200 A IGBT module for higher voltage applications, complementary to the 5SHX1960L0004 3BHL000390P0104 in multi-level converters.

PFEA113-20: Tension measurement system, whose control signals adjust the 5SHX1960L0004 3BHL000390P0104-based drives in steel rolling processes.

ACS880-07-363A-7: ABB’s industrial drive, integrating the 5SHX1960L0004 3BHL000390P0104 module for high-power motor control.

DCS880-02-160A-05: DC drive system, using the module for rectification and inversion in high-current applications.

IGBT gate drivers (ABB GD100): Optimize switching performance of the 5SHX1960L0004 3BHL000390P0104, providing overvoltage protection and isolated signals.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the 5SHX1960L0004 3BHL000390P0104 on a flat, clean heat sink using M6 screws (torque 8 Nm). Apply thermal grease (ABB recommended: 35 mg/cm²) to ensure <0.1°C/W thermal resistance. Connect DC bus capacitors (rated ≥1700 V) within 10 cm of the module to reduce stray inductance. Use 35 mm² copper busbars for main current paths, torquing connections to 12 Nm. Wire gate signals with twisted-pair cables (0.5 mm²) to minimize noise.

Maintenance suggestions: Inspect quarterly for thermal grease degradation—reapply if resistance exceeds 0.2°C/W. Check busbar connections annually for tightness (re-torque if needed). Monitor junction temperature via built-in NTC thermistor; replace module if temperature exceeds 150°C during operation. Store spare modules in dry, ESD-safe packaging (≤60% humidity) at 5-30°C. Avoid mechanical stress on terminals during handling.

Service and guarantee commitment

ABB provides a 1-year warranty for the 5SHX1960L0004 3BHL000390P0104, covering manufacturing defects and premature failures under rated conditions. Technical support offers 24/7 assistance for thermal design, gate driver integration, and fault analysis.

Customers access application notes, thermal simulation tools, and reliability data via ABB’s Semiconductor Portal. Optional services include on-site thermal testing and training on IGBT handling. ABB guarantees spare parts availability for 5 years post-production, ensuring long-term support for critical power conversion systems.