Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

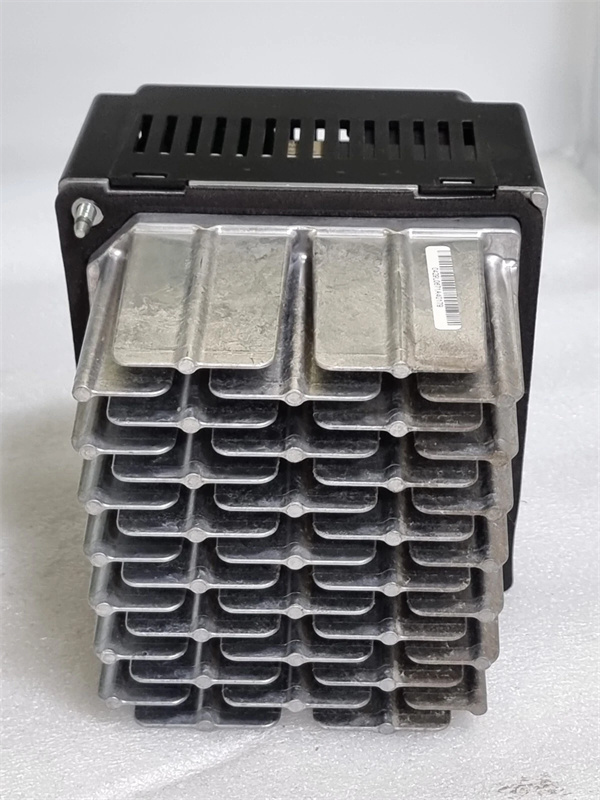

| Product Model | ABB 3HAC14550-4/04B |

| Manufacturer | ABB |

| Product Category | Robot Controller Module (IRC5 Compact System) |

| Controller Type | IRC5 Compact Single Cabinet Controller |

| Robot Compatibility | ABB IRB 120, IRB 140, IRB 1600, YuMi series, and other small-to-medium payload robots |

| Processor | ARM Cortex-based real-time robot controller |

| Axis Control Capacity | Up to 6 axes (standard) |

| I/O Capacity | Integrated 16 DI / 16 DO; Expandable via DSQC I/O modules |

| Communication Interfaces | Ethernet (LAN), USB, Serial (RS232), Profibus DP Slave (optional), DeviceNet (optional) |

| Motion Performance | ABB TrueMove™ and QuickMove™ motion control technology |

| Safety Certification | ISO 10218-1, IEC 61508 SIL 2 (with SafeMove) |

| Power Supply | 200-600V AC, 50/60 Hz (Single or 3-phase) |

| Operating Temperature | 0°C to +45°C (Air-cooled) |

| Storage Temperature | -25°C to +55°C |

| Protection Rating | IP54 (Cabinet) |

| Dimensions (H×W×D) | 450 × 250 × 210 mm |

| Weight | Approx. 15 kg |

| Programming Language | RAPID |

ABB 3HAC14550-4/04B

Product Introduction

The ABB 3HAC14550-4/04B is the core controller module within ABB’s highly successful IRC5 Compact robot control system. Designed specifically for smaller industrial robots and collaborative applications, this integrated cabinet provides a complete motion control solution in a significantly reduced footprint compared to standard IRC5 systems. As the central nervous system, the ABB 3HAC14550-4/04B executes the RAPID program, processes sensor inputs, drives servo motors with precision, and ensures safe operation. It forms the essential hardware platform for robots like the IRB 120, IRB 140, and YuMi series.

Technically positioned as an optimized solution for space-constrained environments and cost-sensitive applications, the ABB 3HAC14550-4/04B integrates the main computer, motion controller, power supply, and basic I/O into a single, compact enclosure. Its core function is to translate high-level task commands into precise, coordinated motion of the robot axes while maintaining real-time control and safety monitoring. The ABB 3HAC14550-4/04B controller enables robots to perform tasks such as material handling, assembly, machine tending, packaging, and light fabrication with high speed and repeatability.

Within the automation ecosystem, the value of the ABB 3HAC14550-4/04B lies in its ability to deliver the advanced motion control capabilities ABB is renowned for (TrueMove™, QuickMove™) in a smaller, simpler package. It simplifies integration, reduces installation costs, and offers a lower total cost of ownership for applications that don’t require the extensive expansion capabilities of the larger IRC5 cabinets. It brings industrial-grade robotic automation within reach for a wider range of manufacturing scenarios.

Core Advantages and Technical Highlights

The ABB 3HAC14550-4/04B delivers significant advantages tailored to compact robotic applications:

Optimized Space and Integration: The most defining feature of the ABB 3HAC14550-4/04B is its compact, single-cabinet design. Integrating all essential control components drastically reduces the required footprint compared to traditional multi-cabinet robot controllers. This simplifies machine layout, eases installation in crowded production cells, and lowers overall system integration costs. Its IP54 rating allows it to be mounted closer to the robot, minimizing cabling requirements.

Advanced Motion Control Performance: Despite its size, the ABB 3HAC14550-4/04B fully incorporates ABB’s proprietary TrueMove™ and QuickMove™ motion control technologies. TrueMove™ ensures predictable path accuracy regardless of speed or payload, critical for precision tasks like assembly and insertion. QuickMove™ optimizes acceleration and deceleration profiles, enabling faster cycle times without sacrificing path precision or causing excessive vibration. This results in smoother paths, shorter cycle times, and higher throughput.

Integrated Safety with SafeMove: The ABB 3HAC14550-4/04B provides a robust foundation for safety. It supports ABB’s SafeMove functionality (requires additional configuration and safety I/O), enabling features like axis position and speed monitoring, standstill supervision, and safe limited spaces. This allows collaborative applications (when paired with appropriate robots like YuMi) or safe operation in close proximity to human workers, achieving SIL 2/PLe safety levels as per standards.

Simplified Connectivity and Expandability: The controller comes equipped with essential communication interfaces (Ethernet, USB, RS232) for programming, HMI connection, and basic PLC integration. Crucially, it offers optional fieldbus modules (Profibus DP Slave, DeviceNet) for seamless connection to factory automation networks. While integrated I/O is sufficient for many tasks, the ABB 3HAC14550-4/04B also supports expansion using ABB’s standard DSQC I/O modules for larger applications.

Reliability and Reduced TCO: Built on ABB’s proven IRC5 platform technology, the ABB 3HAC14550-4/04B inherits exceptional reliability. Its simplified architecture, with fewer external connections and cables compared to larger systems, inherently reduces potential failure points. Lower energy consumption due to optimized power supplies and reduced cooling requirements contributes to a lower total cost of ownership over its operational lifespan.

Typical Application Scenarios

The ABB 3HAC14550-4/04B controller excels in applications demanding high performance in a compact form factor:

Small Parts Assembly & Electronics Manufacturing: Ideal for precision assembly of consumer electronics, PCBs, medical devices, and micro-components. The ABB 3HAC14550-4/04B‘s high path accuracy (TrueMove™) and speed (QuickMove™) ensure delicate handling and fast, precise placement of small parts. Its compact size fits easily into cleanroom or bench-top automation stations.

Machine Tending for CNC & Injection Molding: Perfectly suited for loading/unloading smaller CNC machines, lathes, and injection molding presses. The controller’s robustness, integrated I/O, and optional fieldbus connectivity allow for seamless coordination with the machine tool cycle. Its small footprint is crucial in crowded manufacturing floors.

Packaging & Picking/Palletizing (Lightweight): Efficiently handles primary and secondary packaging tasks, case packing, and palletizing of light-to-medium weight boxes or bags. The ABB 3HAC14550-4/04B enables fast cycle times and smooth motion paths needed for efficient packaging lines, especially where space for automation is limited.

Material Handling & Logistics: Used for part transfer, sorting, kitting, and light material handling within work cells or small automated warehouses. Its reliability and ease of integration make it a workhorse for repetitive transfer tasks.

Collaborative Applications (with YuMi): The ABB 3HAC14550-4/04B is the standard controller for ABB’s YuMi collaborative robots. It manages the robot’s precise, safe motions and integrates seamlessly with the YuMi vision system and grippers for tasks requiring close human-robot interaction, such as small assembly, testing, and kitting.

Laboratory Automation & Research: Its compact size, precision, and programmability make the ABB 3HAC14550-4/04B well-suited for automated testing, sample handling, and research applications in controlled environments.

ABB 3HAC14550-4/04B

Related Model Recommendations

ABB 3HAC14550-4/04A: The predecessor or similar variant of the 3HAC14550-4/04B. May have minor hardware or firmware differences. Often interchangeable but requires verification.

ABB 3HAC14551-1 (Teach Pendant – FlexPendant): The essential programming and operator interface unit (HMI) used with the 3HAC14550-4/04B controller. Available in various models (e.g., 6-axis joystick).

ABB 3HAC17213-1 (SMB Unit – Robot): The Serial Measurement Board located inside the robot manipulator. Critical for motor feedback; connects via the SMB cable to the controller. Unique to each robot.

ABB 3HAC14431-1 (SMB Cable): The vital cable connecting the 3HAC14550-4/04B controller to the SMB unit inside the robot. Transmits motor feedback and power. Specific length required per robot model/installation.

ABB DSQC 652 (I/O Module – 16 DI/16 DO): A standard digital I/O module used to expand the input/output capabilities of the 3HAC14550-4/04B controller beyond its integrated I/O.

ABB DSQC 1030 (Fieldbus Adapter – Profibus DP Slave): Optional module that plugs into the 3HAC14550-4/04B to enable communication with Profibus DP master systems (PLCs).

ABB 3HAC055799-001 (Drive Module): While integrated into the compact cabinet, this refers to the internal power stage responsible for driving the robot motors. A critical internal component.

ABB 3HAB8101-8 (Cable Pack – Robot to Controller): The complete set of cables (Motor Power, Feedback, Brake Release) required to connect a specific robot model to the 3HAC14550-4/04B controller.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the ABB 3HAC14550-4/04B, ensure the installation site meets requirements: solid mounting surface, adequate clearance (≥ 200mm top/sides for cooling), ambient temperature within 0-45°C, and low dust/humidity. Verify correct mains voltage (200-600V AC). Have necessary tools: appropriate screwdrivers, torque wrench for power terminals, crimping tools for I/O wiring, and an ESD wrist strap. Review robot and controller documentation thoroughly. Ensure the robot manipulator and all safety equipment (e.g., emergency stops, safety gates) are ready. Plan cable routing carefully, separating power and signal cables.

Maintenance Suggestions: Regularly clean the ABB 3HAC14550-4/04B cabinet vents to prevent dust buildup and ensure proper cooling. Perform visual inspections for loose connections, damaged cables, or signs of overheating. Monitor controller status LEDs and utilize RobotStudio or the FlexPendant for system diagnostics and error log reviews. Back up robot programs and system parameters regularly using RobotStudio. Adhere strictly to ABB’s recommended maintenance schedule for the specific robot model. When replacing components (e.g., fans), use only genuine ABB spare parts. Perform firmware updates as recommended by ABB, following their procedures precisely. Ensure only qualified personnel perform maintenance.

Service and Guarantee Commitment

ABB provides a standard warranty for the ABB 3HAC14550-4/04B robot controller, typically covering defects in materials and workmanship for 18 months from the date of shipment or 12 months from commissioning, whichever occurs first (subject to ABB’s standard terms and conditions). Warranty details are confirmed upon order.

ABB offers comprehensive global support for the ABB 3HAC14550-4/04B. This includes access to extensive online resources (manuals, application notes, FAQs), MyRobotStudio support portal, and direct technical support through ABB’s local service organizations. ABB provides a wide range of training courses covering IRC5 operation, programming (RAPID), maintenance, and troubleshooting. Field service engineers are available worldwide for on-site commissioning, preventive maintenance, and repair services. ABB is committed to the long-term support and availability of spare parts for the IRC5 platform. Customers investing in the ABB 3HAC14550-4/04B receive the assurance of ABB’s global expertise and dedication to maximizing uptime and productivity in robotic automation.