Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

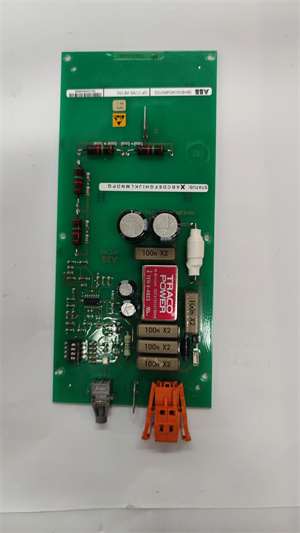

| Product Model | UFC765AE102 (3BHE003604R0102) |

| Manufacturer | ABB |

| Product Category | High-availability CPU Module |

| Processor | 800 MHz Power Architecture® |

| Memory | 64 MB SDRAM / 128 MB Flash |

| Redundancy | Triple Modular Redundant (TMR) |

| Communication Ports | 2x Ethernet, 1x RS-232, 1x USB |

| Protocols Supported | PROFIBUS DP, Modbus TCP, OPC UA |

| Operating Temperature | -25°C to +70°C |

| Power Consumption | 12W @ 24 VDC (±10%) |

| Certifications | SIL 3, ATEX, IEC 61508, UL 508 |

| MTBF | >750,000 hours |

| Physical Dimensions | 155 x 125 x 85 mm (H x W x D) |

ABB 3BHE003604R0102 UFC765AE102

Product Introduction

The ABB UFC765AE102 (3BHE003604R0102) is a fault-tolerant CPU module within ABB’s AC 800M High Integrity controller series, engineered for critical process safety applications. Designed for triple modular redundancy (TMR), this industrial computing powerhouse executes safety instrumented functions (SIF) with SIL 3 certification, making it indispensable in hazardous environments. The UFC765AE102 integrates seamlessly into ABB’s System 800xA DCS architecture, serving as the computational core for shutdown systems, fire & gas detection, and turbine control.

Featuring hardened real-time operating system (RTOS) technology, the ABB UFC765AE102 delivers deterministic sub-millisecond response times while maintaining full diagnostic coverage. Its dual-layer cybersecurity framework combines hardware-enforced memory protection with encrypted OPC UA communications, safeguarding against both operational faults and cyber intrusions. For mission-critical installations, the UFC765AE102’s “2-out-of-3” voting logic ensures continuous operation even during component failures.

Core Advantages and Technical Highlights

Ultra-High Availability:

The ABB UFC765AE102 implements hardware-level TMR architecture where three independent processors execute identical tasks simultaneously. Mismatch detection triggers automatic failover within 50 ms, achieving 99.9999% uptime. This exceeds nuclear industry standards for fault containment.

Functional Safety Compliance:

Certified for SIL 3 (IEC 61508) and SC 3 (IEC 61850-3), the module’s “safe state” design forces outputs to predefined positions during faults. Built-in HART 7 pass-through enables valve diagnostics without separate gateways.

Engineering Flexibility:

Control Builder M engineering tools support drag-and-drop Safety Application Builder (SAB) logic, reducing validation time by 60%. Online module firmware updates via USB eliminate shutdowns. The UFC765AE102’s backward compatibility with UFC720/721 series simplifies legacy upgrades.

Cybersecurity Fortification:

Integrated secure boot with cryptographic signature verification prevents unauthorized code execution. PROFISafe protocol encapsulation ensures end-to-end data integrity across PROFIBUS networks.

Typical Application Scenarios

In offshore oil platforms, the ABB UFC765AE102 orchestrates emergency shutdown (ESD) systems, processing signals from gas detectors and pressure transmitters to isolate hydrocarbon inventories within 200 ms during leaks. Its ATEX-compliant design withstands corrosive salt spray environments.

Power utilities deploy the UFC765AE102 for turbine protection logic, synchronizing with <a href=”https://new.abb.com/control-systems/control-system-hardware/controllers/ac-800m” target=”_blank”>ABB S800 I/O</a> to execute overspeed trips at 10 kHz sampling rates. In LNG liquefaction plants, it manages burner management systems (BMS), utilizing HART diagnostics to predict control valve failures 3 months in advance.

Chemical batch reactors rely on its SIL 3-certified interlock sequences to prevent runaway reactions. The module’s -25°C cold-start capability ensures reliability in Siberian petrochemical facilities.

ABB 3BHE003604R0102 UFC765AE102

Related Model Recommendations

UFH760A: TMR-compatible fieldbus module for PROFIBUS PA device integration.

S800 I/O Series: SIL 2-certified analog/digital modules (e.g., SD826 16ch DI).

CI854: Ethernet communication interface for OPC UA Pub/Sub.

PP845: Profibus DP master module for UFC765AE102 expansion.

TA566: Termination assembly for redundant CPU mounting.

3BSE050091R65: Redundant power supply (24VDC/10A).

UFC762AE101: Lower-tier CPU for non-safety applications.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Maintain ambient humidity below 95% non-condensing. Ground chassis to <1 Ω resistance using AWG 6 cable. Use ESD-safe tools during handling. Mount the UFC765AE102 vertically in DIN rail slots 1-3 (redundant configuration). Required: Torque screwdriver (0.6 N·m for terminals), ABB Control Builder M V11.3+.

Maintenance Suggestions:

Bi-annually: Verify CPU synchronization via System 800xA Diagnostics View. Monitor “VOTING MISMATCH” counters; >5/month indicates hardware degradation. Replace cooling fans every 5 years (P/N 3BSE012719R1). For firmware updates, use write-protected USB drives with ABB-signed packages. Store configuration backups on SD card (slot on front panel).

Service and Guarantee Commitment

ABB provides a 36-month warranty for the UFC765AE102, covering component defects and workmanship. Global technical support includes 24/7 critical incident response with guaranteed 4-hour remote diagnostics and 72-hour on-site intervention for SIL 3 systems.

Lifecycle management includes guaranteed spare parts availability for 15 years post-discontinuation. Extended service agreements offer predictive maintenance through ABB Ability™ Asset Health Center, analyzing vibration/thermal trends from embedded sensors. All UFC765AE102 modules undergo 500-hour accelerated aging tests simulating 10 years of operational stress prior to shipment.