Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

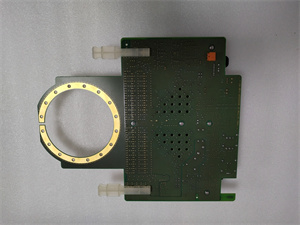

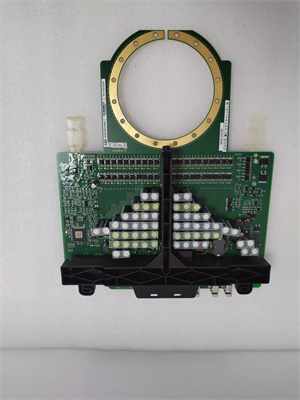

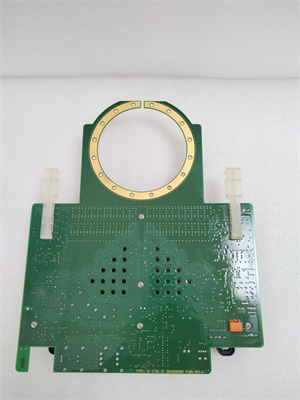

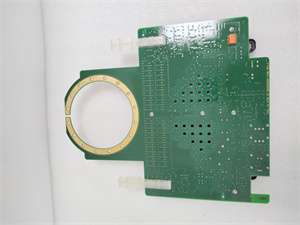

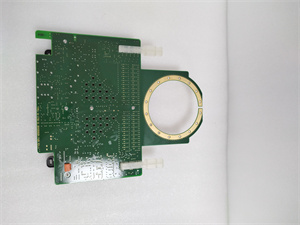

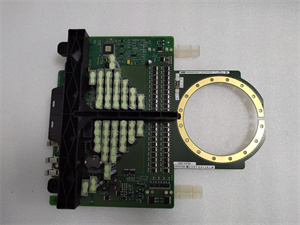

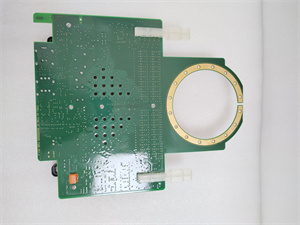

| Product Model | ABB 3BHB045647R0003 |

| Manufacturer | ABB |

| Product Category | Drive Control Module |

| Series | ACS 800 Industrial Drive |

| Input Voltage | 24V DC (±10%) |

| Power Consumption | 18W typical |

| Operating Temp | -25°C to +55°C |

| Communication | PROFIBUS DP, Modbus RTU |

| Processor | 32-bit RISC with DSP |

| Memory | 8MB Flash, 4MB RAM |

| Protection Rating | IP20 (IP54 with enclosure) |

| Dimensions | 120 × 80 × 40 mm |

| Weight | 500g |

| Certifications | CE, UL, cUL, IEC 61800-5-1 |

Product Introduction

The ABB 3BHB045647R0003 is a high-performance drive control module designed for ABB’s ACS 800 series of industrial drives. This advanced module serves as the intelligent control center for variable speed drive applications, providing precise motor control in demanding industrial environments.

As part of ABB’s industrial drive portfolio, the 3BHB045647R0003 offers robust performance for applications requiring accurate speed and torque control. Its modular design allows for flexible configuration and easy integration with various automation systems, making it particularly valuable in industries such as mining, metals, and heavy machinery.

3BHB045647R0003

Core Advantages and Technical Highlights

Precision Control:

32-bit RISC processor with DSP capabilities

±0.5% speed control accuracy

Support for both scalar and vector control modes

Industrial Connectivity:

Dual communication protocols (PROFIBUS DP and Modbus RTU)

ABB DriveCom protocol for system integration

Optional fieldbus extensions available

Rugged Design:

Wide operating temperature range (-25°C to +55°C)

Vibration resistant (2g) and shock proof (5g)

Optional IP54 enclosure for harsh environments

Advanced Diagnostics:

Built-in self-monitoring functions

Comprehensive fault logging with timestamps

Predictive maintenance capabilities

Safety Features:

Safe torque off (STO) functionality

IEC 61800-5-1 compliant safety

Overload and short circuit protection

3BHB045647R0003

Typical Application Scenarios

Mining and Minerals:

Conveyor belt speed control

Crusher and mill drive applications

High-torque material handling

Metals Industry:

Rolling mill drives

Extruder control systems

Continuous casting applications

Oil and Gas:

Pump control in refineries

Compressor drives for pipelines

Offshore platform applications

Marine and Heavy Industry:

Crane and hoist control

Winch drive systems

Large fan and pump applications

Related Model Recommendations

ABB 3BHB045647R0001 – Base version with standard features

ABB 3BHB045647R0002 – Enhanced communication options

ABB 3BHE021887R0101 – Brake chopper module

ABB 3BHE024855R0101 – Interface module

ABB 3BHE039203R0101 – Power supply module

ABB 3BHB007209R0001 – High-performance alternative

ABB 3BHB003154R0001 – Compact version for space constraints

Installation, Commissioning and Maintenance

Installation Guidelines:

Mount in well-ventilated control cabinet

Maintain minimum clearance of 50mm around module

Use shielded cables for communication ports

Ensure proper grounding for noise immunity

Commissioning:

Configure using ABB DriveWindow software

Perform motor identification run

Verify communication settings

Test safety functions before operation

Maintenance:

Regular firmware updates recommended

Monitor heat dissipation and cooling

Check error logs periodically

Annual preventive maintenance advised

Service and Guarantee Commitment

ABB provides:

24-month standard warranty

Global technical support network

On-site commissioning assistance

Repair and refurbishment services

Firmware updates and security patches

Training programs for maintenance staff