Description

1. Product Description

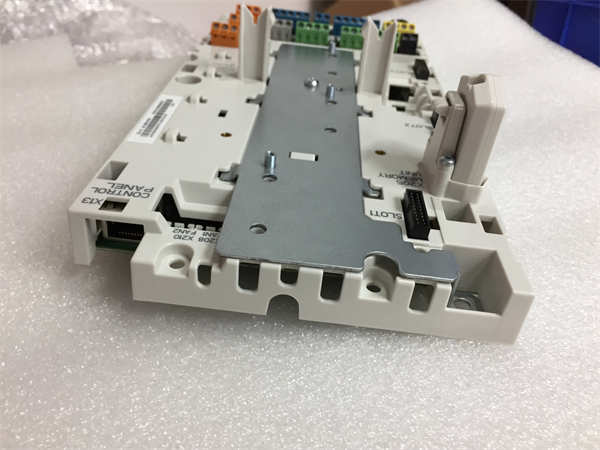

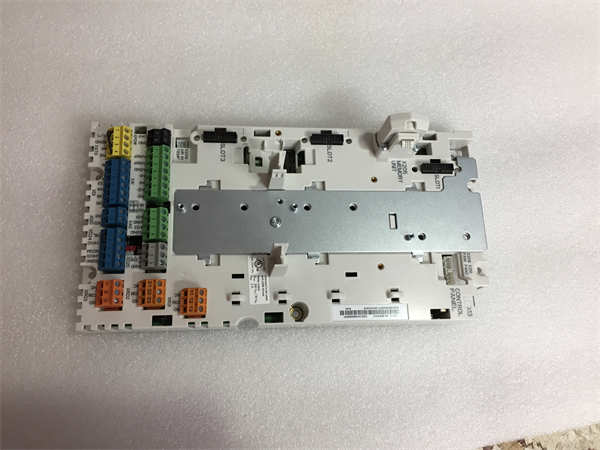

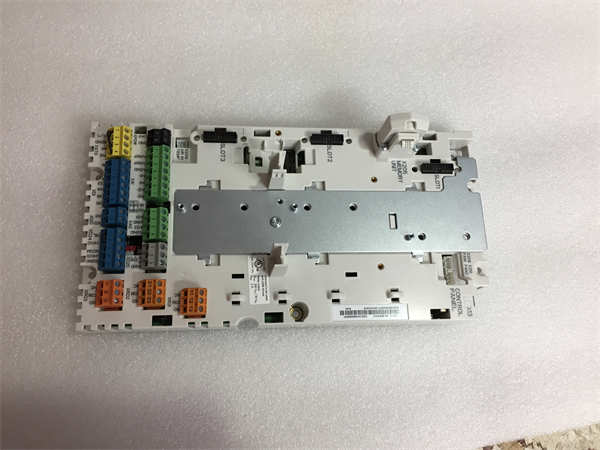

The ABB ZCU-12 is a high-performance control unit designed for industrial automation systems, specifically engineered for ABB’s ACS880 series drives. As a central processing unit (CPU) module, the ZCU-12 plays a critical role in managing motor control, data processing, and communication within industrial environments. It serves as the interface between field devices, such as sensors and actuators, and higher-level control systems, ensuring seamless integration and real-time operation.

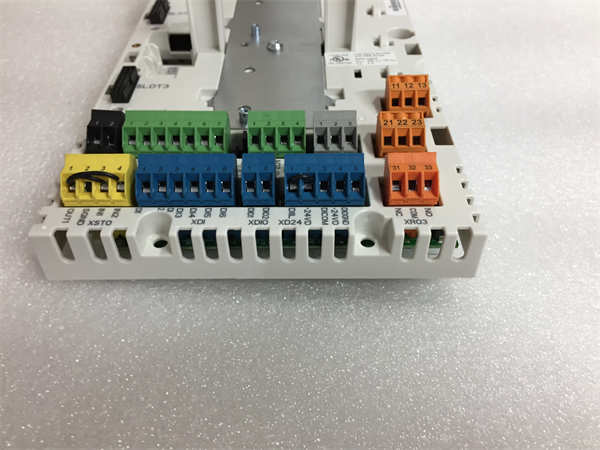

Built with rugged components, the ZCU-12 is designed to withstand harsh conditions, including extreme temperatures (-20°C to +60°C) and high electrical noise. Its modular architecture allows for flexible configuration, supporting both digital and analog input/output (I/O) channels to adapt to diverse application requirements. The unit also features advanced communication capabilities, supporting protocols like Profibus, Modbus, and CANopen, making it compatible with a wide range of industrial networks.

The ZCU-12 stands out for its reliability and efficiency, with a mean time between failures (MTBF) exceeding 100,000 hours. Its intuitive design simplifies installation and maintenance, while its compact size (120mm x 150mm x 80mm) optimizes space in control cabinets. Whether used in manufacturing, energy production, or process industries, the ZCU-12 ensures stable operation and precise control, enhancing overall system performance.

2. Product Specifications

| Parameter | Details |

|---|---|

| Module Type | Central Processing Unit (CPU) for ABB ACS880 drives |

| Voltage Supply | 24V DC (±10% tolerance) |

| Communication Protocols | Profibus DP, Modbus RTU, CANopen, Ethernet/IP (optional) |

| I/O Configuration | 16 digital inputs, 8 analog outputs (12-bit resolution) |

| Processor | Proprietary 32-bit microprocessor |

| Memory | 512 MB RAM, 256 MB flash memory |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Resistance | 5% to 95% RH (non-condensing) |

| Mounting | DIN rail or panel mount |

| Certifications | CE, UL, CSA, RoHS compliant |

ZCU-12

3. Advantages and Features

- High Reliability: With an MTBF of over 100,000 hours, the ZCU-12 minimizes downtime in critical operations. Its robust design includes surge protection and electromagnetic compatibility (EMC) features to ensure stable performance in high-noise environments.

- Flexible Communication: Supports multiple industrial protocols, enabling seamless integration with legacy and modern control systems. This versatility reduces the need for additional adapters, simplifying system setup.

- Wide Temperature Range: Operates reliably in extreme temperatures (-20°C to +60°C), outperforming many competitors that have narrower operational limits.

- Modular Architecture: Allows for easy expansion with additional I/O modules, making it suitable for scalable automation projects.

- Real-Time Diagnostics: Built-in self-diagnostic tools identify faults proactively, reducing maintenance time and costs.

4. Application Areas and Case Studies

The ZCU-12 is widely used in industries such as:

- Manufacturing: Machine control, assembly lines, and robotics.

- Energy: Power plant automation, renewable energy systems (wind/solar farms), and grid management.

- Process Industries: Chemical plants, oil and gas facilities, and water treatment plants.

Case Study: A large automotive manufacturing plant integrated the ZCU-12 into its robotic welding system. The unit’s high-speed processing and reliable communication protocols reduced cycle times by 15% while improving weld quality consistency. Its ability to handle multiple I/O signals simultaneously also simplified coordination between robots and conveyor systems, enhancing overall production efficiency.

5. Competitive Comparison

When compared to similar industrial control units (e.g., Siemens Simatic S7-1500 or Schneider Modicon M580), the ZCU-12 offers:

- Superior Temperature Tolerance: Operates in a broader temperature range (-20°C to +60°C) compared to many alternatives (typically -10°C to +55°C).

- Native Protocol Support: Integrates Profibus, Modbus, and CANopen without additional modules, reducing hardware costs.

- Compact Design: Occupies 30% less space in control cabinets, ideal for space-constrained environments.

- Long Lifespan: Higher MTBF (100,000+ hours) compared to competitors (typically 80,000–90,000 hours).

ZCU-12

6. Selection Recommendations

When choosing the ZCU-12 or similar modules, consider the following:

- System Compatibility: Ensure your control system supports the ZCU-12’s communication protocols (e.g., Profibus DP, Modbus).

- Environmental Conditions: Verify that the operating temperature and humidity align with your application’s requirements.

- I/O Needs: Confirm that the 16 digital inputs and 8 analog outputs meet your data acquisition and control demands.

- Scalability: If future expansions are planned, leverage the ZCU-12’s modular design for easy integration of additional modules.

- Budget: Balance the ZCU-12’s premium features (e.g., high-speed processing) with your project’s budget constraints.

7. Precautions

- Electrical Safety: Disconnect power before installing or servicing the module to prevent electrostatic discharge (ESD) damage.

- Cable Management: Use shielded cables for signal connections to minimize interference in high-noise environments.

- Firmware Updates: Regularly update firmware through ABB’s official tools to access the latest features and security patches.

- Mounting: Install the module in a well-ventilated enclosure to maintain optimal operating temperatures.

- Memory Unit Replacement: When replacing the memory unit, follow ABB’s guidelines to avoid data loss (refer to the ACS880 hardware manual for detailed steps).

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.