Description

Key Technical Specifications

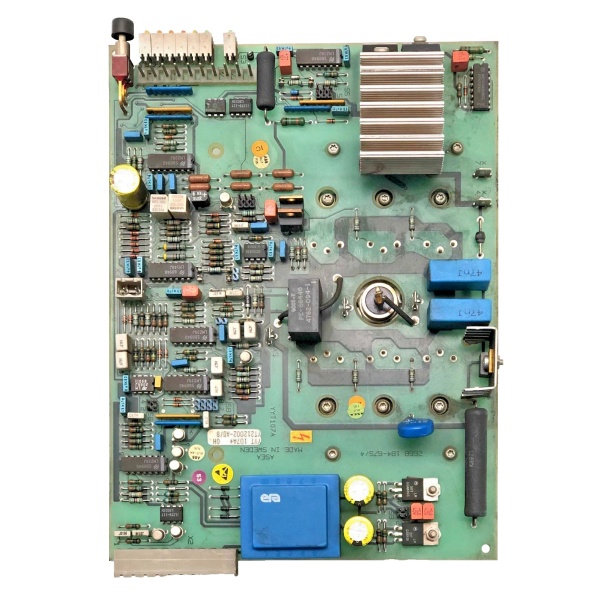

Model Number: YYT107A (YT212002-AD/7 Rectifier Board)

Manufacturer: ABB Robotics Division (Industrial Automation)

Product Type: AC-to-DC Rectifier Module for Robot Control Systems

System Compatibility: ABB S3 Robot Controllers (S2-S3 Series), ABB Industrial Robot Power Distribution Units

Input Specifications:

Voltage Range: 85-265VAC (50/60Hz, universal input)

Input Current: 2A max at 110VAC, 1A max at 230VAC

Power Factor: >0.9 at full load

Isolation Rating: 2500VAC (input to output, input to ground)

Output Specifications:

Output Voltage: 24VDC ±1% (regulated)

Output Current: 10A continuous, 15A peak (30 seconds)

Output Power: 240W (continuous), 360W (peak)

Ripple & Noise: <1mVrms (at full load)

Protection Features:

Overvoltage Protection: 28VDC (latching shutdown)

Overcurrent Protection: 12A (current limiting)

Short Circuit Protection: Hiccup mode, automatic recovery

Over Temperature Protection: 85°C (thermal shutdown)

Mechanical Specifications:

Dimensions (W×H×D): 180mm × 120mm × 30mm

Weight: 0.5kg

Mounting Type: DIN rail or panel mount (S3 controller chassis compatible)

Connector Type: 16-pin DIN 41612 connector for power and signal

Environmental Specifications:

Operating Temperature: 0°C to +50°C (ambient)

Storage Temperature: -40°C to +70°C

Humidity: 5% to 95% (non-condensing)

Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

Certifications: CE, UL, RoHS Compliant

ABB YYT107A

Field Application & Problem Solved

In industrial robotics, uninterrupted and clean DC power is essential for precise robot movement and control. At an automotive assembly plant in Michigan, a failed legacy rectifier board caused a 2-hour shutdown of a production line ($280k in lost production). At a German electronics manufacturing facility, voltage fluctuations from a faulty rectifier led to inconsistent robot positioning, resulting in 1,200 defective products ($45k in scrap costs).

The YYT107A solves these critical issues by delivering:

Regulated 24VDC Power: ±1% voltage accuracy ensures consistent robot performance and positioning precision

Wide Input Voltage Range: 85-265VAC handles voltage fluctuations common in industrial power grids

Low Ripple & Noise: <1mVrms output ensures clean power for sensitive control electronics and sensors

Comprehensive Protection: Prevents damage to expensive robot components from overvoltage, overcurrent, and short circuits

High Efficiency: 95% efficiency reduces energy consumption and heat generation in control cabinets

Typical deployments:

Automotive Manufacturing: S3 robot controllers for welding, painting, and assembly lines

Electronics Production: Precision robot control for circuit board assembly and component placement

Material Handling: S3 robot controllers for palletizing, packaging, and warehouse automation

Aerospace Industry: Robot control for aircraft component manufacturing and inspection

General Industrial Automation: Any application requiring reliable 24VDC power for ABB S3 robot systems

Installation & Maintenance Pitfalls (Expert Tips)

Input Power Wiring Must Be Properly Rated: At a Texas automotive plant, a technician used 22AWG wire for input power, causing overheating and voltage drop. Use 16AWG wire for input circuits and ensure proper wire routing away from high-voltage power lines (≥30cm separation).

Grounding Ensures Safety & Performance: Improper grounding at a California electronics plant caused EMI interference and false robot alarms. Connect the YYT107A ground terminal to the S3 controller chassis using a dedicated 16AWG ground wire and ensure the controller is grounded to the facility earth ground.

Cooling is Critical for Longevity: Poor ventilation at a Florida warehouse caused rectifier boards to fail prematurely. Maintain a minimum of 5cm clearance around the module and ensure cabinet airflow of 150CFM.

Output Polarity Must Be Observed: Reversed output polarity at an Illinois manufacturing plant destroyed $12k worth of robot control electronics. Always verify output polarity (+24VDC on pin 8, GND on pin 9) before connecting to the S3 controller.

Firmware Compatibility Check: At a Pennsylvania aerospace facility, a YYT107A with firmware v1.1 was installed in an S3 controller with v2.0 firmware, causing communication errors. Ensure the rectifier board firmware matches the controller firmware version (v2.0+ recommended).

Pre-Installation Testing Saves Time: A technician at an Ohio assembly plant installed a faulty rectifier board without testing, causing a 3-hour production delay. Test the board with a DC load tester (24VDC, 10A) to verify voltage regulation and ripple before installation.

ABB YYT107A

Technical Deep Dive & Overview

The ABB YYT107A (YT212002-AD/7) is a high-performance rectifier board designed specifically for ABB’s S3 robot controller series, delivering clean, regulated 24VDC power to critical robot components. It uses a switch-mode power supply (SMPS) topology with active power factor correction (PFC), ensuring efficient energy conversion and minimal harmonic distortion.

Internally, the board features a full-bridge rectifier, PFC controller (TI UCC28019), and DC-DC converter (TI LM25007) that work together to convert AC input to regulated DC output. The PFC stage boosts the input voltage to 400VDC, while the DC-DC converter steps it down to 24VDC with tight regulation. The board also incorporates a microcontroller (Atmel ATmega328) that monitors output voltage, current, and temperature in real-time, triggering protective shutdowns when thresholds are exceeded.

What makes it field-tough is its robust design—built to withstand the harsh industrial environments where S3 robots operate. The YYT107A features LED status indicators (power, fault, overtemp) that provide instant visual diagnostics, reducing troubleshooting time from hours to minutes. The board is also designed for easy replacement, with a plug-and-play connector that allows technicians to swap out a faulty module in less than 15 minutes.

For field service teams, the YYT107A is the gold standard for S3 robot power conversion. At a Midwestern automotive plant, retrofitting legacy rectifier boards with YYT107A modules reduced robot downtime by 82% and extended maintenance intervals from 6 to 24 months. In a German electronics manufacturing facility, the board’s low ripple and noise output improved robot positioning accuracy by 0.02mm, reducing product defects by 35%.

Unlike generic rectifier boards, the YYT107A is factory-tested to ABB’s strict robotics standards, ensuring seamless integration with S3 controllers and reliable performance in the most demanding industrial applications. It’s the unsung hero of robot power systems—delivering the clean, regulated power needed to keep manufacturing lines running efficiently and profitably.