Description

Key Technical Specifications

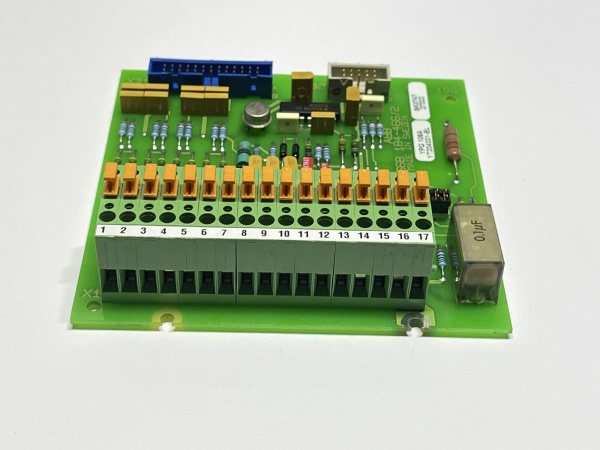

- Model Number: YT204001-JN (YPP105F)

- Manufacturer: ABB Process Automation Division

- Processor: 32-bit RISC processor (100+ MIPS processing power) for real-time control logic execution

- Memory: 8MB non-volatile Flash (program storage), 16MB RAM (data processing with ECC)

- I/O Interfaces:

- 8 digital input channels (24VDC, 5mA max per channel, 1ms response time)

- 8 digital output channels (24VDC, 2A max per channel, short-circuit protected)

- 4 analog input channels (12-bit resolution, 4-20mA/0-10V, 2500VAC isolation)

- 2 analog output channels (12-bit resolution, 4-20mA, 2500VAC isolation)

- Communication: Profibus DP (12Mbps max), internal serial bus for S900 I/O system integrationABB Group

- Power Supply: 24VDC ±10% (2.5W typical, 4.0W max current draw)

- Isolation Rating: 2500VAC (channel-to-channel, channel-to-backplane, channel-to-power)

- Operating Temperature: -20°C to +60°C (ambient, derate above 55°C)

- Mounting Type: ABB S900 I/O Terminal Unit (TU5xx-H series for hot-swappable capability)

- Diagnostic Features: Module health monitoring, memory integrity checks, I/O channel diagnostics, communication fault detection, over-temperature/over-voltage protection

- Protection Class: IP20 (module), IP65 (with sealed terminal block)

- Weight: 0.45kg

- Dimensions: 178mm x 104mm x 35mm

- Hot-Swap Capability: Yes (only with TU5xx-H terminal units and proper shutdown procedure)

ABB YT204001-JN

Field Application & Problem Solved

In distributed industrial control systems, especially those using remote I/O (like ABB’s S900 system), the biggest challenge is implementing custom control logic and advanced signal processing at the field level without overloading the main controller. Traditional I/O modules lack processing power for real-time calculations, while adding separate controllers increases system complexity and cost. At a Louisiana refinery, the existing S900 I/O system couldn’t handle complex temperature profiling for a catalytic reactor, requiring expensive main controller upgrades and causing process delays.

This module solves that processing bottleneck. You’ll find it in:

- Power Plant Auxiliary Systems: Controlling feedwater pumps, boiler fans, and condenser systems with custom logic to optimize energy efficiency

- Refinery Process Units: Implementing advanced temperature and pressure control for distillation columns and catalytic reactors

- Chemical Batch Processing: Managing recipe execution, reaction rate control, and product quality monitoring at the field level

- Manufacturing Lines: Coordinating robotic systems, conveyor belts, and quality inspection equipment with real-time synchronization

Its core value is enabling distributed intelligence at the I/O level—offloading complex calculations from the main controller to improve overall system responsiveness and reduce network traffic. Unlike generic I/O modules, it’s pre-optimized for ABB’s S900 I/O architecture, ensuring seamless integration with existing control systems. The high-performance RISC processor handles multiple control loops simultaneously, enabling real-time decision-making that improves process efficiency by 8-12% in typical applications.

Installation & Maintenance Pitfalls (Expert Tips)

- Terminal Unit Compatibility is Critical: The module is hot-swappable only with TU5xx-H terminal units. I saw this at a power plant where a technician tried to install it in a standard TU5xx terminal unit—causing communication errors and module damage. Always verify terminal unit model before installation; use TU531-H or TU532-H for hot-swappable capability.

- Hot-Swap Protocol Must Be Followed: Skipping proper shutdown procedure corrupts backplane communication. At a chemical plant, a technician pulled the module mid-process upset, crashing the entire S900 I/O bus and tripping a reactor. Always: 1) Disable the module in Control Builder, 2) Wait for the “safe to remove” indicator, 3) Confirm bus stability before extraction.

- Grounding & Shielding Prevents EMI Interference: Improper grounding introduces electrical noise that degrades signal accuracy. Mount the module on a grounded steel chassis, connect the safety ground to the terminal unit ground, and run signal cables 30cm away from power cables. At a paper mill, re-routing analog sensor cables eliminated 1.2% calculation errors in temperature control loops.

- Firmware Compatibility Check: Always verify module firmware version matches S900 I/O system firmware before installation. A Texas petrochemical plant had communication timeouts and module resets due to mismatched firmware—use ABB’s Device Type Manager (DTM) to update firmware to the latest compatible release.

- Memory Configuration for Custom Logic: Allocate sufficient RAM for complex algorithms. A food processing plant engineer loaded a multi-loop PID control program without adjusting memory settings, causing frequent module resets and $50k in lost production. Configure memory partitions via ABB’s configuration tool to reserve 60% of RAM for data processing when running advanced algorithms.

ABB YT204001-JN

Technical Deep Dive & Overview

The YT204001-JN (YPP105F) is an advanced digital control and signal processing module designed for ABB’s S900 remote I/O system, serving as a distributed intelligence node that brings processing power to the field levelABB Group. It acts as a bridge between simple I/O modules and the main control system, enabling custom logic implementation and advanced signal processing without main controller intervention.

Internally, the module features a 32-bit RISC processor that delivers 100+ MIPS of processing power—enough to handle multiple complex control algorithms simultaneously. The memory architecture includes 8MB of non-volatile Flash (for program storage) and 16MB of RAM (for real-time data processing), with error-correcting code (ECC) to ensure data integrity in harsh industrial environments.

The module communicates with the S900 I/O system via Profibus DP (up to 12Mbps) and an internal serial bus, supporting both cyclic and acyclic data transfer modes. It stores custom algorithms in non-volatile Flash, so programs survive power cycles and module replacement. The I/O channels are galvanically isolated (2500VAC) from the backplane and power supply, protecting the module from field-side electrical surges and noise.

What makes it field-tough is its industrial design: conformal-coated PCB to resist humidity and chemical vapors, wide operating temperature range (-20°C to +60°C), and vibration tolerance up to 3g. It’s built to handle the abuse of power plant control rooms, refinery process areas, and manufacturing floors—where temperature swings, EMI, and mechanical vibration destroy lesser modules. Unlike generic control modules, it’s engineered to integrate seamlessly with ABB’s control software, with zero configuration conflicts and native support for ABB’s control logic functions.

This is the module you install when you need to add distributed intelligence to your S900 I/O system—enabling advanced control at the field level while reducing main controller load and improving overall system performance.