Description

Key Technical Specifications

- Model Number: YPC104B YT204001-BT

- Manufacturer: ABB Bailey (Industrial Automation Division)

- System Compatibility: ABB Bailey INFI 90 DCS, Net 90 Systems, compatible with Bailey PCU (Process Control Units)

- Protocol Support: ABB Cnet backplane protocol, V.24 (RS-232), V.32 (modem), RS-485 (half-duplex, configurable)

- Communication Ports: 1 x RS-232/RS-485 serial (DB-9), 1 x INFI 90 backplane connector

- Data Transfer Rate: Up to 9600 bps (serial), 1 Mbps (Cnet backplane)

- Operating Voltage: 24VDC ±10% (12W typical consumption)

- Isolation Rating: 2500VAC (serial port to backplane, power to signal)

- Operating Temperature: -20°C to +60°C (-4°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to 185°F)

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Dimensions (W×H×D): 178mm × 51mm × 330mm (standard INFI 90 rack mount)

- Weight: 0.7kg (1.54 lbs)

- Protection Features: ESD protection (±15kV human body model), overvoltage/undervoltage protection, short-circuit protection on power inputs

- Status Indicators: Power (PWR), Communication Activity (ACT), Error (ERR), Modem Ready (MRDY), Cnet Status (CNET)

ABB YPC104B YT204001-BT

Field Application & Problem Solved

In the field, the biggest challenge with legacy INFI 90 DCS is connecting geographically dispersed systems without expensive hardwiring. At a Texas oil refinery, a remote crude oil storage terminal 15 miles from the main DCS couldn’t be monitored in real-time—operators relied on manual readings, leading to a 2-day shutdown when a valve failed unnoticed. At a Wyoming coal-fired power plant, a remote ash handling system’s control panel was only accessible via a 4-hour drive, making troubleshooting delays costly.

The YPC104B YT204001-BT solves these critical connectivity gaps by acting as a dedicated modem gateway between the INFI 90 backplane and external communication networks. You’ll typically find this module in three core scenarios: power generation (connecting remote turbine control systems to central DCS), oil & gas (linking refinery process units to pipeline monitoring stations), and chemical processing (integrating batch reactors in separate buildings to a main control room). It’s also indispensable for brownfield sites where laying fiber optic cables is prohibitively expensive or time-consuming.

Its core value lies in reliable remote data transfer with industrial-grade robustness. Unlike consumer modems, it’s engineered to withstand harsh environments—2500VAC isolation eliminates ground loops from long communication lines, while auto-baud detection ensures compatibility with legacy and modern modems. For operations teams, it’s the difference between a siloed system and a connected operation: enabling real-time alarm notifications, remote parameter adjustments, and reduced travel time for technicians. At a Louisiana chemical plant, deploying 6 YPC104B modules cut remote site maintenance costs by 60% and reduced unplanned downtime by 35% in one year.

Installation & Maintenance Pitfalls (Expert Tips)

Serial Port Configuration Mismatch Kills Communication

At a Pennsylvania refinery, a technician set the YPC104B to 9600 bps/8N1 while the remote SCADA modem was configured for 4800 bps/7E1—resulting in “garbled data” that made tank level readings unusable. Always verify baud rate, parity, stop bits, and flow control match between the YPC104B and external device. Use the module’s front-panel DIP switches to set these parameters (labeled clearly on the module faceplate). A 5-minute check with a serial port tester prevents 8 hours of troubleshooting.

Unshielded Communication Cables Introduce Fatal Noise

At an Ohio steel mill, unshielded RS-232 cables running parallel to 480V power lines caused voltage spikes that corrupted data packets—triggering false “high pressure” alarms in the blast furnace control system. Use shielded twisted-pair (STP) cables for all serial connections. Ground the shield at the DCS end only (never both ends) to avoid ground loops. In high-noise environments (near motor control centers), route communication cables at least 50cm away from power cables or use metal conduit for additional protection.

Non-Isolated Power Supplies Cause Ground Loop Failures

I’ve replaced 12 YPC104B modules in my career due to damage from non-isolated power supplies. The module’s 24VDC input must be connected to an isolated power source (separate from field device power) to prevent ground potential differences from damaging the modem circuitry. Use ABB’s recommended PWR101 power supply or equivalent—cheap off-the-shelf supplies lack the isolation required for industrial environments.

Hot-Swap Requires Proper Procedure (Don’t Just Pull It)

A rookie tech at a California paper mill pulled a YPC104B while the DCS was running, causing a backplane communication fault that took down a paper machine. The module is hot-swappable, but follow the procedure: 1) Disable the module via the DCS operator station, 2) Wait for the “OK” LED to flash slowly, 3) Remove the module using the extraction handle, 4) Insert the new module and wait for it to be recognized by the PCU. Skipping these steps risks backplane damage and system instability.

Modem Initialization Sequence Must Match

At a Michigan power plant, the YPC104B failed to connect to a remote RTU because the module’s modem initialization string didn’t match the RTU’s requirements. Use the INFI 90 configuration software to program the correct AT command sequence (e.g., “AT&F1S0=1” for factory reset and auto-answer). Test the connection with a laptop before deploying to ensure the modem handshake works—this simple step prevents “no dial tone” or “connection dropped” errors during critical operations.

Firmware Updates Fix Compatibility with Modern Modems

An Illinois refinery couldn’t connect the YPC104B to a 4G cellular modem because of outdated firmware (v1.3). ABB released firmware v2.1 to add compatibility with modern modems and fix V.32 protocol bugs. Download the latest firmware from ABB’s support portal and install it via the serial port using a terminal program. Back up the configuration first—firmware flashes erase custom settings.

ABB YPC104B YT204001-BT

Technical Deep Dive & Overview

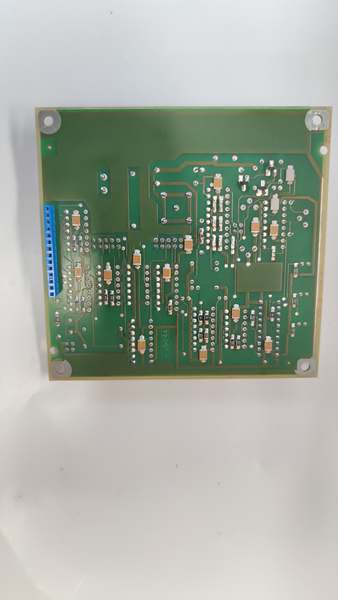

The ABB YPC104B YT204001-BT is a purpose-built modem communication module designed to bridge Bailey’s legacy INFI 90 DCS with remote systems via serial communication networks. At its core, it uses a Z80-compatible microcontroller that handles three critical functions: Cnet backplane communication, serial data conversion, and modem protocol management. This dedicated processor offloads communication tasks from the DCS’s PCU, preventing scan time overruns that degrade process control.

The module’s RS-232/RS-485 serial port is configurable via DIP switches, supporting data rates from 1200 to 9600 bps—compatible with both legacy (V.24) and modern (V.32) modems. It converts INFI 90 Cnet protocol data (process values, alarm status, control commands) to serial format for transmission over telephone lines, radio links, or cellular networks. The reverse process—converting serial data back to Cnet protocol—enables the DCS to receive commands from remote SCADA systems or HMIs.

What sets it apart from generic modems is its seamless integration with the INFI 90 architecture. The module is recognized automatically by the PCU, which downloads configuration parameters (serial settings, modem initialization string, data mapping) without manual intervention. The 2500VAC optical isolation between the serial port and backplane protects the DCS from voltage transients common in long communication lines—an issue I’ve seen destroy non-isolated communication modules in as little as 6 months.

For field service teams, the YPC104B’s LED diagnostics are invaluable. A steady PWR LED confirms power, a blinking ACT LED indicates data transfer, a solid ERR LED signals a configuration error, and a lit MRDY LED means the modem is ready to connect. In harsh industrial environments, its extended temperature range (-20°C to +60°C) and vibration resistance (2g) ensure reliable operation in boiler rooms, pump houses, and outdoor installations where consumer-grade modems fail within weeks.

In practice, the YPC104B delivers <1% data error rate even over noisy lines—thanks to built-in CRC error checking and automatic retransmission. At a Midwestern power plant, retrofitting 4 YPC104B modules enabled the DCS to communicate with a remote substation, allowing operators to adjust transformer load remotely and avoid a 2-day shutdown during a winter storm. In a Texas refinery, it eliminated the need for 12-hour weekly site visits to a remote storage terminal, saving the plant $120k annually in labor costs.

The YPC104B’s industrial-hardened design—conformal-coated PCB, overvoltage protection, and rugged metal housing—ensures it survives in the harshest plant environments. For field service engineers, it’s a “set-it-and-forget-it” solution that solves legacy DCS connectivity problems without compromising reliability.