Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

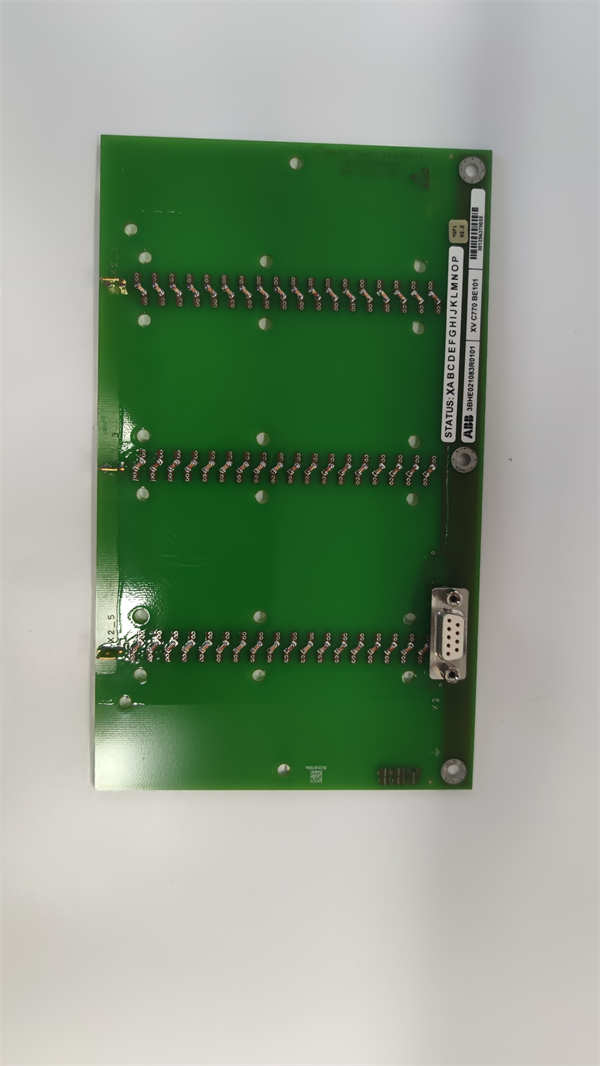

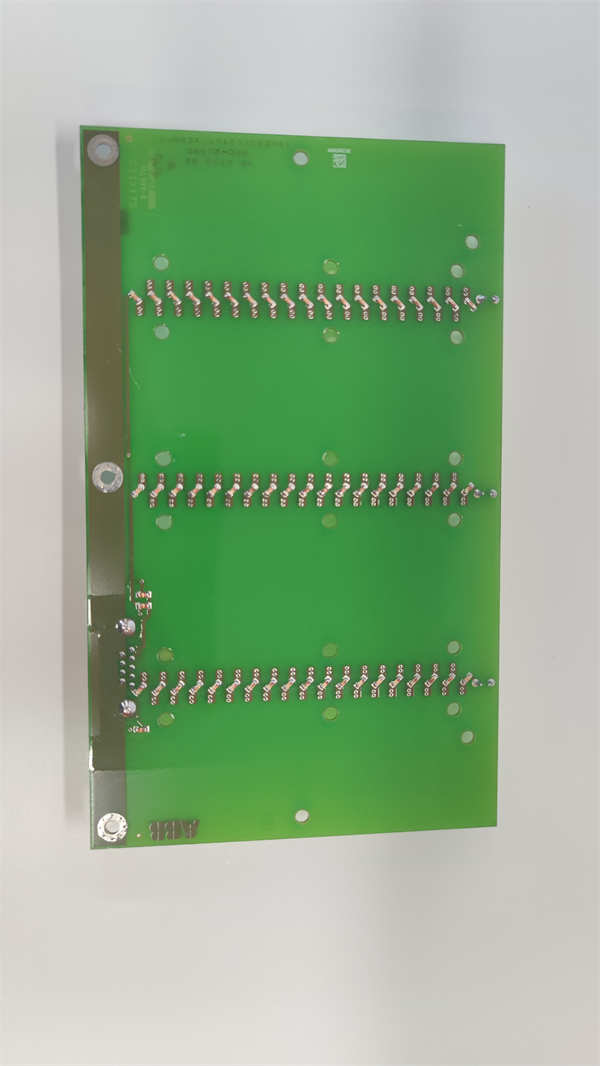

| Product Model | XVC770BE101 3BHE021083R0101 |

| Manufacturer | ABB |

| Product Category | DCS Controller Module (Symphony Plus Series) |

| Processor | Single-Core 1.2 GHz Power Architecture |

| Memory | 1 GB DDR3 RAM + 4 GB Flash |

| Redundancy Support | None (Simplex Configuration) |

| Communication Interfaces | 2x 100 Mbps Ethernet, 1x PROFIBUS DP, 1x RS-485 |

| Protocols Supported | Modbus RTU/TCP, OPC DA, IEC 60870-5-104 |

| Control Execution Speed | ≤ 250 ms cycle time (1,000 I/O points) |

| Operating Temperature | -25°C to +70°C (Derating >55°C) |

| Power Consumption | 8 W @ 24 V DC |

| I/O Capacity | Supports up to 8,000 I/O Points |

| Certifications | UL 508, CE, DNV-GL, IEC 60068 (Shock/Vibration) |

| MTBF | >200,000 hours |

XVC770BE101 3BHE021083R0101

Product Introduction

The ABB XVC770BE101 3BHE021083R0101 is a cost-optimized controller within ABB’s Symphony Plus distributed control system, designed for non-redundant applications in power distribution, water treatment, and industrial machinery. This compact module executes regulatory control and sequencing functions with deterministic performance, featuring native integration with Harmony I/O subsystems via high-speed S+Bus communication. As an essential component of ABB’s scalable automation architecture, the XVC770BE101 supports legacy protocols like IEC 60870-5-104 while providing migration paths to modern OPC connectivity.

Engineered for space-constrained panels, the controller delivers 85% of the processing power of redundant counterparts at 60% cost. Its extended temperature tolerance (-25°C to +70°C) enables deployment in transformer substations and outdoor enclosures without climate control. The ABB XVC770BE101 3BHE021083R0101 maintains full compatibility with Control Builder M engineering tools, allowing seamless configuration transfer between Symphony Plus controller tiers.

Core Advantages and Technical Highlights

Cost-Effective Performance:

Optimized single-core architecture delivers 500+ IEC 61131-3 function blocks execution within 250 ms, suitable for pump control, burner management, and batch sequencing applications.

Legacy Protocol Integration:

Native PROFIBUS DP master/slave capability connects to existing field devices without gateways. Integrated IEC 60870-5-104 stack enables direct SCADA communication for grid-tied systems.

Compact Footprint:

Half-width design (compared to redundant controllers) fits 25% more I/O in standard racks. Low power consumption enables use in solar-powered remote installations.

Robust Environmental Tolerance:

Operates at 70°C with 1.5% annual failure rate. Vibration-resistant design (5g @ 10-150Hz) certified for rolling stock applications.

Cybersecurity Fundamentals:

Hardware-enforced firmware signature verification prevents unauthorized code execution. Configurable firewall restricts network access to authorized engineering stations.

Typical Application Scenarios

Water Pumping Stations: Controls multi-pump sequencing with level logic in municipal systems using ≤100ms scan times.

HVAC Energy Plants: Manages heat exchanger networks in district heating systems via PROFIBUS-connected valve actuators.

Material Handling: Executes conveyor interlocking logic in warehouse automation with 500+ digital I/O points.

Solar Inverter Control: Regulates 1500V DC arrays through IEC 60870-104 communication to SCADA.

Compressed Air Systems: Implements VSD control algorithms for industrial compressors with analog I/O expansion.

Related Model Recommendations

XVC769AE101: Redundant counterpart for critical processes.

PP825: Power supply unit compatible with XVC770BE101 chassis.

SD834: Diagnostic module for performance monitoring.

CI871K01: PROFIBUS interface expansion.

TA527: Digital input module (32pt) for high-density switching.

S+ Operations: Visualization platform for XVC770BE101 data.

COM523: Serial communication module for legacy device integration.

XVC770BE101 3BHE021083R0101

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Verify rack compatibility (HPC20/HPC40 chassis). Maintain ≥40mm clearance on sides for heat dissipation. Ground chassis with 6 AWG copper wire. Use ESD protection during handling. Pre-load configuration via USB service port before power-up.

Maintenance Protocol:

Monitor CPU load via S+ Diagnostics (sustained >75% requires optimization). Replace cooling fans every 3 years in dusty environments. Perform annual firmware validation checks. Maintain air filters in enclosed panels to prevent thermal derating.

Service and Guarantee Commitment

ABB offers 24-month standard warranty extendable to 5 years. Support includes:

48-hour hardware replacement for registered users

Lifetime firmware security patches

Remote diagnostics via Secure Connect Gateway

On-demand configuration optimization services

Extended maintenance plans provide:

Preventive component replacement

Emergency onsite support (72-hour global response)

Cybersecurity health checks

All controllers undergo 96-hour thermal cycle testing before shipment.