Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

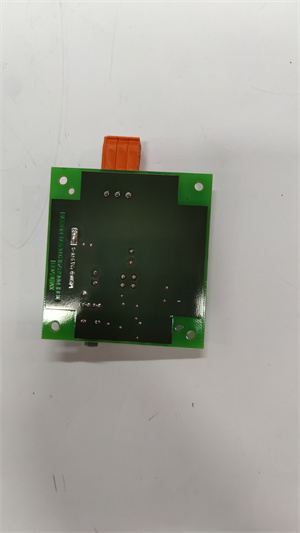

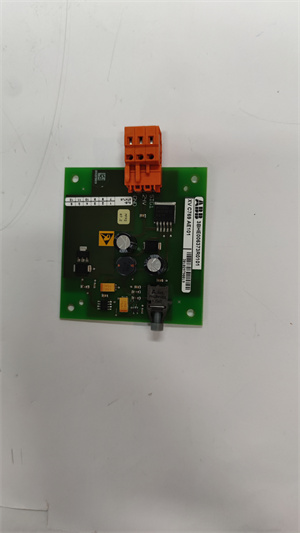

| Product Model | XVC769AE101 3BHE006373R0101 |

| Manufacturer | ABB |

| Product Category | DCS Controller Module (Symphony Plus Series) |

| Processor | Dual-Core 1.5 GHz Power Architecture |

| Memory | 2 GB DDR3 RAM + 8 GB Flash |

| Redundancy Support | Hot-swappable 1:1 Processor Redundancy |

| Communication Interfaces | 2x Gigabit Ethernet, 2x PROFINET, 1x RS-485 |

| Protocols Supported | Modbus TCP, OPC UA, IEC 61850, PROFINET IO |

| Operating Temperature | -40°C to +70°C (Conformal Coating Option) |

| Power Supply | 24 V DC ±20% (Redundant Inputs) |

| I/O Capacity | Supports up to 16,000 I/O Points per Cluster |

| Certifications | UL Class I Div 2, ATEX, IECEx, DNV-GL, CE |

| MTBF | > 300,000 Hours |

ABB XVC769AE101 3BHE006373R0101

Product Introduction

The ABB XVC769AE101 3BHE006373R0101 is a high-availability controller module for ABB’s Symphony Plus distributed control system (DCS), engineered for mission-critical industrial automation in power generation, oil & gas, and chemical processing. This advanced controller integrates dual-core processing power with deterministic real-time performance, executing complex regulatory control, sequence logic, and safety interlocks at millisecond cycle times. As the computational backbone of the Symphony Plus architecture, the XVC769AE101 seamlessly interfaces with Harmony I/O modules, third-party PLCs, and enterprise networks via native support for OPC UA and IEC 61850.

Designed for extreme reliability, the module features hardware-level redundancy with automatic failover (<50 ms switchover) and online maintenance capabilities. Its ruggedized construction includes conformal coating for corrosive environments, making the ABB XVC769AE101 3BHE006373R0101 ideal for offshore platforms, arctic installations, and desert refineries. The controller’s integrated cybersecurity framework complies with IEC 62443, providing secure remote access and firmware integrity protection.

Core Advantages and Technical Highlights

Fault-Tolerant Architecture:

Dual processors with synchronized memory execute parallel computations, ensuring zero data loss during failover events. The XVC769AE101’s 1:1 redundancy extends to power supplies and network paths, achieving >99.999% availability for safety-critical processes.

Deterministic Performance:

Real-time VxWorks OS guarantees sub-100ms control loop execution, even with 5,000+ function blocks. Hardware-accelerated PROFINET IO processing minimizes jitter for motion control applications.

Cybersecurity by Design:

Embedded Trusted Platform Module (TPM) enables secure boot, encrypted communications, and role-based access control. Supports automated certificate management and audit trails compliant with NERC CIP and IEC 62443-3-3.

Scalable Integration:

Native IEC 61131-3 and C/C++ programming environments allow hybrid control strategies. The controller’s OPC UA Pub/Sub capability enables MES/ERP integration without middleware.

Extreme Environment Resilience:

Operates continuously at 70°C ambient temperature without derating. Optional conformal coating protects against H₂S, salt fog, and humidity per ISA-71.04 Class G3.

Typical Application Scenarios

Combined-Cycle Power Plants: Coordinates gas/steam turbines and balance-of-plant systems using <10ms closed-loop control, with automatic fallback during grid disturbances.

FPSO Vessel Process Control: Manages crude separation trains in Class I Div 2 zones, leveraging ATEX certification and seawater corrosion resistance.

Ethylene Cracker Furnaces: Executes advanced ratio control and decoking sequences with 50+ interlocks per furnace, surviving 65°C control room temperatures.

Hydrogen Production Facilities: Integrates electrolyzer safety systems (SIL 2) via PROFIsafe over the XVC769AE101’s PROFINET interfaces.

Water Treatment Networks: Synchronizes pumping stations across 100km pipelines using IEEE 1588 PTP time-sensitive networking.

Related Model Recommendations

XVC768BE101: Non-redundant version of XVC769AE101 for non-critical processes.

HIA401: Harmony analog input module (16-channel) for direct sensor integration.

S+ Operations: ABB’s operator workstation software for XVC769AE101 visualization.

CI871K01: PROFIBUS DP interface module for legacy device integration.

XUO116A 3BSE050091R116: Digital output module (32-point) for actuator control.

SD835 3BSE018105R1: System diagnostic tool for predictive maintenance of XVC769AE101.

PP825 3BSE042240R1: Redundant power supply unit compatible with controller chassis.

SCY15258: Conformal coating kit for harsh-environment deployment.

ABB XVC769AE101 3BHE006373R0101

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

De-energize the Symphony Plus rack before insertion. Verify chassis slot compatibility (requires HPCxx series). Ground the cabinet per EN 60204-1 using 10 AWG minimum wire. Maintain 100mm clearance above/below the XVC769AE101 for airflow. Use ESD wrist straps when handling.

Maintenance Protocol:

Monitor module health via S+ Engineering diagnostics. Replace every 5 years in high-vibration environments. Perform firmware updates during planned shutdowns using ABB’s System Update Manager. Validate redundancy switchover quarterly via forced failover test. For corrosion-prone sites, inspect conformal coating integrity annually using UV light (per IPC-A-610).

Service and Guarantee Commitment

ABB provides a 36-month warranty for the XVC769AE101 3BHE006373R0101, extendable to 10 years through Life Cycle Service agreements. Global support includes:

24/7 critical failure response with 4-hour onsite SLA for power generation customers

Firmware updates with backward compatibility assurance for 15+ years

Cybersecurity patch delivery within 72 hours of vulnerability disclosure

Complimentary System Health Check using ABB Ability™ diagnostics

Loaner module program during repairs

Training at ABB University covers controller programming, cybersecurity hardening, and disaster recovery. All modules undergo 168-hour burn-in testing with thermal cycling prior to shipment.