Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | XVC767AE102 / 3BHB007209R0102 |

| Manufacturer | ABB |

| Product Category | Memory Extension Module for AC 800M Controllers |

| Compatible Controller | AC 800M High Performance Series (e.g., PM864A, PM865) |

| Memory Type | Synchronous DRAM (SDRAM) |

| Memory Capacity | 4 MB |

| Function | Program & Data Storage Extension |

| Voltage Requirement | 3.3V DC (supplied via controller backplane) |

| Error Correction | ECC (Error Correcting Code) Support |

| Redundancy Support | Enables Triple Modular Redundancy (TMR) configuration |

| Physical Dimensions (WxHxD) | Approx. 110 mm x 25 mm x 125 mm |

| Mounting | Direct plug-in to controller CPU unit |

| Operating Temperature | -25°C to +70°C (-13°F to +158°F) |

| Relative Humidity | 5% to 95% (non-condensing) |

| Certifications | CE, UL, cULus, ATEX (specific variants) |

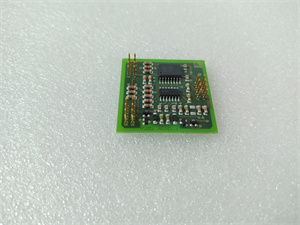

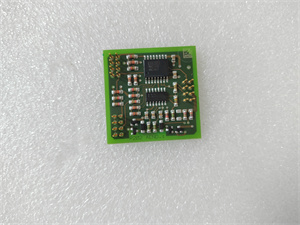

ABB XVC767AE102 3BHB007209R0102

Product Introduction

The ABB XVC767AE102 3BHB007209R0102 is an essential Memory Extension Module designed specifically for the AC 800M High Performance Process Control Controllers (PCC). This module provides critical additional program and data storage capacity, enabling the execution of larger, more complex automation applications within ABB’s flagship 800xA or Symphony Plus distributed control systems. Its core function is to expand the onboard memory resources of controllers like the PM864A or PM865, ensuring they can handle extensive control logic, data logging, and advanced function blocks required in modern industrial automation.

As part of ABB’s S800 I/O family within the AC 800M platform, the XVC767AE102 3BHB007209R0102 plays a vital role in enhancing the controller’s computational capabilities. Technically positioned as a high-reliability memory expansion, it interfaces seamlessly via the controller’s dedicated internal bus. This module is indispensable when projects scale beyond the base memory capacity of the CPU, particularly for applications involving historian functions, complex batch sequencing, or extensive custom algorithms. The inclusion of ECC memory protection in the XVC767AE102 safeguards against data corruption, a critical feature for maintaining process integrity and safety in demanding environments. Its value lies in future-proofing control systems, allowing for application growth without requiring a full controller upgrade.

Core advantages and technical highlights

The ABB XVC767AE102 3BHB007209R0102 delivers significant advantages for mission-critical control systems:

Critical Redundancy Enabler: A primary function of the XVC767AE102 is its mandatory role in configuring Triple Modular Redundancy (TMR) systems. Three controllers, each equipped with this module, operate in lockstep. The module ensures all three processors have identical program and data images, enabling continuous voting and fault tolerance. If one controller fails, the remaining two maintain uninterrupted control – a cornerstone for Safety Instrumented Systems (SIS) and high-availability processes in oil & gas or power generation.

Enhanced Application Capacity: By adding 4MB of dedicated SDRAM, the XVC767AE102 significantly extends the capabilities of AC 800M controllers. This allows engineers to implement larger control strategies, incorporate more sophisticated diagnostics, store greater volumes of process data locally, and utilize advanced function blocks without compromising execution speed or risking memory overflow errors, crucial for complex refining or chemical processes.

Data Integrity Assurance: The integrated ECC (Error Correcting Code) technology is a critical reliability feature. It automatically detects and corrects single-bit memory errors and detects multi-bit errors in real-time. This proactive protection prevents undetected data corruption that could lead to erroneous control actions or process trips, significantly enhancing overall system Mean Time Between Failures (MTBF) and operational safety.

Seamless Integration and Robustness: Designed specifically for the AC 800M backplane, the XVC767AE102 requires no complex configuration or external power. Its plug-in design ensures reliable connectivity and simplifies installation or replacement. Built to ABB’s stringent industrial standards, it operates reliably across a wide temperature range (-25°C to +70°C) and in high-humidity environments, making it suitable for global deployment in diverse plant conditions. Its certifications (CE, UL, cULus, ATEX options) underscore its suitability for hazardous areas and critical infrastructure.

Typical application scenarios

The ABB XVC767AE102 3BHB007209R0102 is indispensable in industries demanding maximum reliability, complex control, and safety:

Power Generation (Thermal, Hydro, Nuclear): Essential for turbine control systems (TMR configuration), boiler management, and feedwater control where high availability is non-negotiable. The memory expansion handles complex sequencing logic for startup/shutdown and extensive alarm management. The XVC767AE102 ensures the massive control programs and safety interlocks operate flawlessly.

Oil & Gas (Upstream, Midstream, Refining): Critical for Safety Instrumented Systems (SIS) protecting offshore platforms, pipelines, and refinery units (FCCUs, reformers) configured in TMR. Also vital for complex process control applications in LNG trains requiring large memory footprints for advanced regulatory control and optimization algorithms. The XVC767AE102‘s reliability is paramount in these high-consequence environments.

Chemical & Petrochemical: Used in large-scale continuous processes like ethylene cracking or polymerization, where complex model predictive control (MPC) strategies and extensive batch/recipe management demand significant controller memory. The ECC protection of the XVC767AE102 safeguards against process upsets caused by memory errors.

Pharmaceutical & Fine Chemicals: Supports intricate batch automation requiring large recipe storage, complex phase logic, and extensive electronic batch recording (EBR) data handling within the controller. The XVC767AE102 enables compliance with stringent data integrity requirements (e.g., FDA 21 CFR Part 11).

Pulp & Paper and Metals: Provides the necessary memory capacity for coordinating large machine sections (e.g., paper machines, rolling mills) involving thousands of I/O points and sophisticated drive coordination logic. The ruggedness of the XVC767AE102 suits harsh mill environments.

Water & Wastewater Management: Enables advanced control strategies for large treatment plants, including energy optimization and predictive maintenance functions requiring additional data storage within the controller.

ABB XVC767AE102 3BHB007209R0102

Related model recommendations

PM864AK01: High-Performance AC 800M Controller CPU – The primary unit where the XVC767AE102 3BHB007209R0102 is installed for memory expansion and TMR capability.

PM865K01: Premium High-Performance AC 800M Controller CPU – A higher-tier CPU also compatible with the XVC767AE102 for demanding applications.

CI854A: Communication Interface (e.g., Profibus DP Master) – A common module used alongside the controller CPU and memory expansion for network connectivity.

SD832: 2MB Serial Communication Module (e.g., Modbus) – Provides additional communication ports often needed in systems utilizing the expanded capabilities of the XVC767AE102.

TP854: Operator Panel Module – Local interface module for controllers expanded with the XVC767AE102.

S800 I/O Modules (e.g., AI810, AO810, DI810, DO810): The primary field I/O units connected to the AC 800M controller, whose data volume often necessitates the extra memory provided by the XVC767AE102.

SA801F: Foundation Fieldbus Linking Device – Interfaces FF segments to the controller; complex FF strategies benefit from the XVC767AE102‘s memory.

XVC768AE101 3BHB007210R0101: Related battery backup module for controller memory retention.

PP825: Power Supply Unit (e.g., for PM86x rack) – Provides power to the chassis housing the controller and XVC767AE102.

PM891K01: Compact AC 800M Controller – A smaller controller option where the larger PM864/PM865 with XVC767AE102 might be over-specified.

Installation, commissioning and maintenance instructions

Installation Preparation: Ensure the AC 800M controller (e.g., PM864A) is powered down. Verify ESD precautions are in place (use wrist strap, grounded workstation). Identify the correct slot adjacent to the CPU module designated for memory expansion. Have the correct mounting screws ready. Check the controller firmware compatibility for the XVC767AE102 3BHB007209R0102. Ensure the operating environment meets specified temperature and humidity ranges. Do not force the module during insertion.

Maintenance Suggestions: The XVC767AE102 requires minimal physical maintenance. Periodically inspect for dust accumulation and clean using compressed air (static-safe) if necessary, ensuring power is off. Monitor controller diagnostics and system logs within the 800xA/Symphony Plus engineering station for any memory-related errors or ECC correction events, which could indicate potential issues. Ensure controller firmware is kept up-to-date per ABB recommendations. When handling or replacing the XVC767AE102, always follow strict ESD procedures to prevent electrostatic damage to sensitive components. In TMR configurations, replace modules during planned maintenance windows and ensure full synchronization after replacement using ABB engineering tools.

Service and guarantee commitment

ABB stands firmly behind the quality and reliability of the XVC767AE102 3BHB007209R0102. The module is covered by ABB’s standard global warranty, typically 24 months from shipment, covering defects in materials and workmanship under normal operating conditions. ABB provides comprehensive technical support through its global network of Automation Service Specialists, offering expert assistance with troubleshooting, configuration, and integration of the XVC767AE102 within AC 800M systems. Repair and replacement services are available, utilizing genuine ABB parts and factory-certified repair processes to restore full functionality. Extended warranty options and customized service level agreements (SLAs) are offered for critical applications. ABB commits to long-term product support and lifecycle management, ensuring availability of the XVC767AE102 and necessary technical documentation. Access to software updates, manuals, and online knowledge resources is provided through the official ABB support portal. Our commitment is to maximize the uptime and performance of your entire control system investment.