Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | XVC767AE102 |

| Manufacturer | ABB |

| Product Category | Compact DCS Controller (Symphony Plus S+ Compact) |

| Processor | Dual-Core 1.0 GHz ARM Cortex-A9 |

| Memory | 2 GB DDR3 RAM + 8 GB eMMC Flash |

| Redundancy Support | Optional 1:1 via XVC767RE101 module |

| Communication Interfaces | 2x Gigabit Ethernet, 2x RS-485, 1x USB 3.0 |

| Protocols Supported | Modbus TCP/RTU, OPC UA, IEC 60870-5-104, DNP3 |

| Control Execution Speed | ≤ 100 ms cycle time (5,000 I/O points) |

| Operating Temperature | -40°C to +70°C (conformal coating standard) |

| Power Supply | 24 V DC ±15% (1.5A max) |

| I/O Capacity | 12,000 points per controller cluster |

| Certifications | UL 61010-1, IEC 60068-2 (vibration/shock), RoHS |

| Cybersecurity | Secure Boot, TPM 2.0, IEC 62443-4-1 compliant |

| MTBF | >220,000 hours |

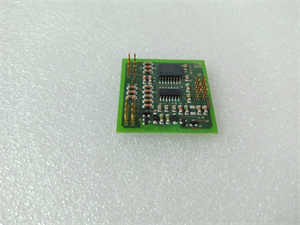

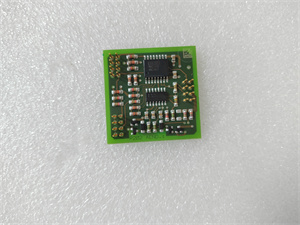

ABB XVC767AE102

Product Introduction

The ABB XVC767AE102 represents the next evolution in ABB’s Symphony Plus S+ Compact controller line, delivering enterprise-grade automation capabilities in a space-efficient footprint. Designed for mid-scale industrial processes and distributed infrastructure, this controller executes complex regulatory control, batch sequencing, and safety interlocks with deterministic sub-100ms performance. As the core processing unit of ABB’s scalable automation ecosystem, the XVC767AE102 seamlessly integrates Harmony Drive I/O and third-party devices through native Modbus and OPC UA connectivity.

Engineered for harsh environments, the controller features military-grade conformal coating as standard protection against humidity, chemical vapors, and conductive dust (per ISA-71.04 Class G3). Its modular architecture supports optional redundancy through the XVC767RE101 companion module, enabling smooth migration from simplex to fault-tolerant configurations without hardware replacement. The ABB XVC767AE102 extends Symphony Plus engineering tools to smaller applications, maintaining full compatibility with Control Builder M for unified programming across ABB’s DCS portfolio.

Core Advantages and Technical Highlights

Optimized Performance Density:

Dual ARM Cortex-A9 cores deliver 2.5x the processing power of previous compact controllers within the same 45mm width, executing 300+ PID loops in ≤50ms.

Cybersecurity by Default:

Integrated Trusted Platform Module (TPM) enables hardware-encrypted communications, secure firmware validation, and role-based access control meeting NERC CIP requirements.

Extreme Environment Resilience:

Operates continuously at 70°C without derating. Vibration resistance to 5g (10-500Hz) and 50g shock tolerance certified for mobile mining equipment.

Seamless Scalability:

Hot-add I/O expansion via S+Bus EX (100Mbps deterministic Ethernet). Supports clustering of up to 8 XVC767AE102 controllers for distributed architecture.

Legacy Integration:

Native DNP3 and IEC 60870-5-104 stacks enable direct RTU replacement without protocol gateways. PROFIBUS DP support via CI854 expansion module.

Typical Application Scenarios

District Energy Networks: Controls heat exchanger stations with adaptive weather compensation algorithms across 50+ substations via OPC UA Pub/Sub.

Wastewater Pumping: Implements dissolved oxygen control in SBR reactors using integrated safety functions (SIL 2 via HIA441 analog input).

Mobile Mining Equipment: Manages conveyor drive synchronization on autonomous haul trucks with vibration-tolerant mounting.

Food & Beverage Batch Processing: Executes FDA-compliant recipe management with electronic signatures in CIP/SIP sequences.

Renewable Hybrid Plants: Coordinates solar/wind/battery systems using DNP3 communication to grid SCADA.

ABB XVC767AE102

Related Model Recommendations

XVC767RE101: Redundancy module for 1:1 failover configuration with XVC767AE102.

HIA441: High-density analog input module (16-channel) for direct sensor integration.

TA536: Digital output module (32-point) with SIL 3 capability.

CI854: PROFIBUS DP interface for legacy device connectivity.

PP827: Compact power supply (24V/5A) for single-controller cabinets.

SD836: Diagnostic module for predictive maintenance analytics.

S+ Operations Compact: HMI software package optimized for XVC767AE102.

XVC768BE102: Non-redundant variant with extended temperature range (-50°C).

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Mount vertically on 35mm DIN rail with minimum 75mm clearance above for heat dissipation. Verify grounding resistance <1Ω between chassis and facility ground. Use shielded CAT6a Ethernet cables with gland entries. Pre-load configuration via USB service port before power-up.

Maintenance Protocol:

Monitor controller health through embedded web server (HTTPS). Replace every 7 years in corrosive environments. Perform firmware updates during planned stops using ABB System Update Manager. Validate cybersecurity settings quarterly via ABB Cyber Asset Management tool. Clean air vents biannually in dusty environments.

Service and Guarantee Commitment

ABB provides a 36-month warranty covering hardware defects and performance specifications. Comprehensive support includes:

Lifetime firmware security updates with 10-year compatibility commitment

24/7 technical support with 4-hour critical response SLA

Onsite commissioning assistance within 5 business days

Loaner controller program for warranty repairs

Complimentary cybersecurity vulnerability assessments

Extended service agreements offer:

Predictive maintenance analytics via ABB Ability™

Emergency spare parts consignment

Controller performance optimization services

All units undergo 500-hour accelerated life testing with thermal cycling (-40°C to +85°C) before shipment.