Description

Key Technical Specifications

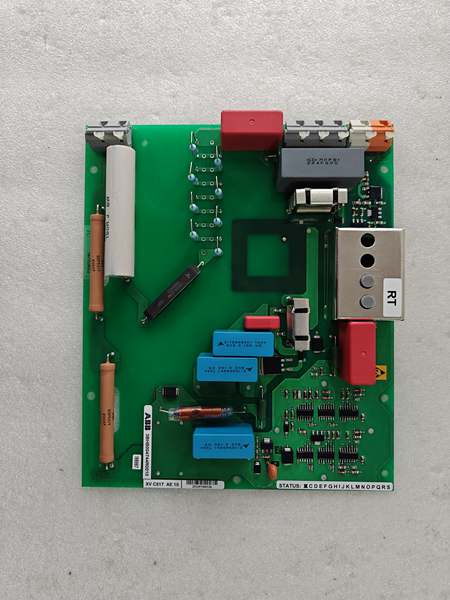

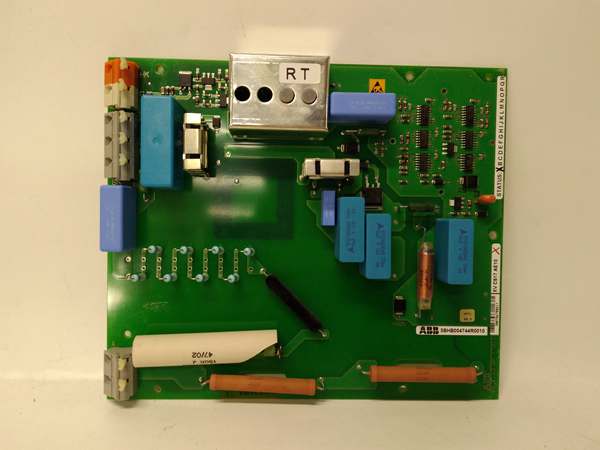

- Model Number: XVC517AE10

- Manufacturer: ABB

- Control Signal Input: 4-20mA DC (proportional control), 24V DC discrete commands

- Feedback Signal Output: 4-20mA DC (valve position, 16-bit resolution)

- Valve Actuator Compatibility: Pneumatic diaphragm actuators, electric actuators (24V DC)

- Operating Temperature: -40°C to +85°C (-40°F to +185°F)

- Storage Temperature: -50°C to +100°C (-58°F to +212°F)

- Isolation: 2.5kV AC (signal lines to power, input to output)

- Power Supply: 24V DC (150mA typical), 18-30V DC operating range

- Response Time: <50ms (signal processing), <200ms (full valve stroke control)

- Protection Features: ESD protection (±25kV), short-circuit protection, over-voltage tolerance

- Dimensions (W x H x D): 95mm x 145mm x 65mm

- Weight: Approx. 380g

- Mounting: Direct actuator mount (NEMA 4/IP66 rated housing)

- Compliance: IEC 61508 (SIL 2 certified), IEC 61000-4 (EMC), UL 1203

- Diagnostic Outputs: Valve stall detection, power loss alert, signal mismatch fault

ABB XVC517AE10

Field Application & Problem Solved

In process industries—refineries, chemical plants, and power stations—the biggest challenge is precise, reliable control of industrial valves amid extreme temperatures, vibration, and corrosive environments. Legacy valve control modules suffer from slow response times, poor fault visibility, or inability to withstand harsh conditions, leading to incorrect valve positioning, unplanned downtime, or safety hazards (e.g., over-pressurization in reactors). This module solves that by combining ruggedized design with smart control and real-time diagnostics, eliminating the “blind spots” of traditional valve controllers.

You’ll typically find this module mounted directly on control valves in critical process loops: think refinery distillation column level control valves, chemical plant reactor feed valves, or power plant boiler steam control valves. It’s also used in water treatment plants (pH adjustment valves) and pulp mills (digester liquor flow valves), where precise positioning directly impacts product quality and process safety. For retrofits, it replaces outdated analog valve controllers, upgrading to digital feedback and diagnostics without requiring actuator replacements—saving time and cost.

Its core value is precision and accountability. The 16-bit resolution feedback ensures valve positioning accuracy within ±0.1%, critical for tight process control (e.g., maintaining exact flow rates in chemical batches). The built-in diagnostics alert operators to valve stalls or signal mismatches before they cause process upsets, while the rugged IP66/NEMA 4 housing withstands rain, dust, and corrosive fumes. For plant operators, this translates to fewer safety incidents, reduced maintenance costs, and consistent process performance—critical in industries where valve failures can lead to catastrophic outcomes.

Installation & Maintenance Pitfalls (Expert Tips)

Direct Actuator Mounting: Torque & Alignment Matter

Rookies often over-tighten the module to the actuator or misalign the position feedback link. Over-tightening warps the housing, compromising the IP66 seal and allowing moisture ingress. Misalignment causes inaccurate position feedback, leading to erratic valve movement. Use a torque wrench set to ABB’s spec (3–5Nm) for mounting bolts. Align the feedback link so it moves freely through the full valve stroke—bind spots will trigger false stall alarms. Test the link’s movement manually before powering up.

Signal Wiring: Avoid Voltage Drops in Long Runs

The 4-20mA control and feedback signals are sensitive to voltage drops in long cable runs. Technicians frequently use undersized wire (22AWG or smaller) for runs over 50m, causing signal degradation. Use 18AWG twisted-pair shielded cable for distances beyond 30m, and keep total loop resistance below 500Ω (including the module’s input impedance). For runs over 100m, use a signal booster—this prevents the controller from misinterpreting weak signals as valve faults.

Ignoring SIL 2 Wiring Requirements

Since the module is SIL 2 certified, improper wiring can compromise safety integrity. Rookies often daisy-chain power supplies or share signal grounds with non-safety circuits. Use a dedicated 24V DC safety-grade power supply for the module, and ensure signal lines are isolated from non-critical wiring. Avoid running control/feedback cables parallel to power cables (maintain 20cm separation) to prevent EMI from corrupting safety-related signals.

Skipping Calibration After Installation

A common mistake is powering up the module without calibrating the position feedback to the valve’s full stroke. This leads to “dead bands” (valve doesn’t move at signal extremes) or over-travel (valve exceeds desired position). Use the module’s calibration mode (via HMI or handheld tool) to map the 4mA signal to the valve’s fully closed position and 20mA to fully open. Verify calibration with a digital multimeter on the feedback signal—this ensures the controller receives accurate position data.

ABB XVC517AE10

Technical Deep Dive & Overview

The ABB XVC517AE10 is a smart valve control module engineered to bridge the gap between central process controllers and industrial valves, delivering precise positioning and real-time health monitoring in harsh environments. At its core, it acts as a translator: converting 4-20mA control signals from the DCS/PLC into mechanical valve movement, while transmitting 4-20mA position feedback back to the controller for closed-loop control.

The module’s internal microprocessor processes control signals in real time, adjusting the output to the actuator (pneumatic pressure or electric current) with <50ms response time. The 16-bit analog-to-digital converter (ADC) for feedback ensures high-resolution position tracking, while built-in diagnostic logic monitors for anomalies: valve stall (no movement despite control signal changes), power loss, or signal mismatch (control vs. feedback). These faults trigger discrete outputs and log data for troubleshooting.

Ruggedness is central to its design: the IP66/NEMA 4 housing is sealed against dust, water, and corrosive agents, while the -40°C to +85°C operating range handles extreme ambient temperatures. The module mounts directly on the valve actuator, eliminating long feedback linkages that introduce wear and inaccuracy. Isolation (2.5kV AC) protects against ground loops and voltage transients, common in industrial electrical systems.

Integration is seamless with standard process control systems—no proprietary software is required for basic operation. Advanced features (calibration, fault logging) are accessible via a handheld configurator or HMI. The SIL 2 certification makes it suitable for safety-instrumented systems (SIS), adding a layer of reliability for critical valves. Overall, it’s a purpose-built solution that prioritizes the industrial reality: valves need to move accurately, stay reliable in harsh conditions, and alert operators when something goes wrong.