Description

Detailed parameter table

| Parameter name | Parameter value |

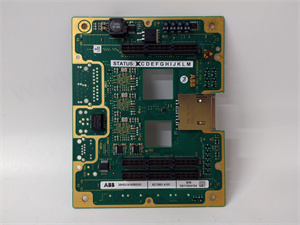

| Product model | XDD501A101 |

| Manufacturer | ABB |

| Product category | Digital output module (AC 800M controller system) |

| Output channels | 16 channels, relay output |

| Output rating | 250 VAC / 30 VDC, 5 A per channel |

| Isolation | 2500 VAC (channel to backplane, channel to channel) |

| Response time | <10 ms (relay actuation) |

| Diagnostic features | Channel-level overload detection, open/short circuit monitoring |

| Communication interface | PROFINET, Modbus TCP/IP |

| Operating temperature | -25°C to 70°C |

| Protection rating | IP20 |

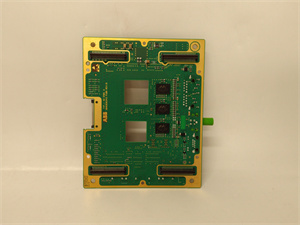

| Dimensions | 120mm × 80mm × 60mm |

| Weight | 0.45kg |

| Certifications | UL 508, IEC 61131-2, CE, ATEX |

| Mounting type | DIN rail (35mm) |

ABB XDD501A101

Product introduction

The ABB XDD501A101 is a high-reliability digital output module designed for seamless integration with ABB’s AC 800M controller system, a cornerstone of modern industrial automation. This module serves as a critical link between the controller and field devices, converting digital control signals from the AC 800M into physical actions by activating external equipment such as motors, valves, and solenoids.

With 16 independent relay outputs, the ABB XDD501A101 offers versatile control capabilities across a wide range of voltage and current ratings, making it suitable for diverse industrial applications. Its robust relay design ensures reliable switching even in harsh environments, while advanced diagnostic features provide real-time insights into channel status, enabling proactive maintenance and minimizing downtime.

Within the AC 800M ecosystem, the ABB XDD501A101 enhances system flexibility by supporting both PROFINET and Modbus TCP/IP protocols, allowing easy integration with existing networks. Whether deployed in manufacturing lines, process plants, or infrastructure projects, this module delivers consistent performance, ensuring precise control of external devices and contributing to overall system efficiency and safety.

Core advantages and technical highlights

Versatile output capabilities: The ABB XDD501A101 supports both AC and DC loads up to 250 VAC/30 VDC with a 5 A current rating per channel, eliminating the need for separate modules for different power types. This versatility allows it to control diverse devices—from 230 VAC conveyor motors to 24 VDC solenoid valves—simplifying system design and reducing inventory costs. The relay outputs handle inrush currents up to 10 A, making them suitable for inductive loads like motor starters without additional protection components.

Enhanced isolation and safety: Featuring 2500 VAC isolation between channels and from the backplane, the ABB XDD501A101 provides superior protection against electrical noise and ground loops. This isolation is critical in industrial environments with high electromagnetic interference, such as near welding machines or high-voltage equipment, ensuring stable operation without signal degradation. The module’s compliance with ATEX and IEC 61131-2 standards further validates its safety in hazardous and general industrial areas.

Comprehensive diagnostics: The ABB XDD501A101 incorporates advanced diagnostic functions, including real-time monitoring of overload conditions and detection of open or short circuits on each channel. Diagnostic data is transmitted to the AC 800M controller, enabling operators to identify issues such as a stuck valve or blown fuse via the HMI. This proactive fault detection reduces troubleshooting time by up to 70% compared to non-diagnostic modules, minimizing unplanned downtime.

Wide temperature tolerance: Operable from -25°C to 70°C, the ABB XDD501A101 thrives in extreme environments, from unheated outdoor enclosures to high-temperature industrial zones like foundries or glass manufacturing facilities. Its ability to maintain performance across this range eliminates the need for climate-controlled cabinets in many applications, reducing installation costs and expanding deployment possibilities.

Typical application scenarios

In automotive manufacturing plants, the ABB XDD501A101 controls robotic welding cells by activating grippers, conveyor motors, and cooling fans. Its 16 channels manage multiple devices within a single cell, while relay outputs handle the mixed AC/DC loads common in such environments. Diagnostic data alerts maintenance teams to issues like a jammed gripper (detected via overload), preventing production line stoppages.

Within water and wastewater treatment facilities, the ABB XDD501A101 operates valve actuators in filtration systems and chemical dosing pumps. Its wide voltage range allows control of both 230 VAC motorized valves and 24 VDC diaphragm pumps, while isolation protects against electrical noise from nearby pumps. The module’s temperature tolerance ensures reliable operation in unheated pump houses during winter months.

In food and beverage processing, the ABB XDD501A101 manages packaging machinery, activating sealers, labelers, and product diverters. Its compliance with UL 508 ensures safety in food-grade environments, while diagnostic features quickly identify issues like a broken sealer heater (detected via open circuit), reducing product waste and maintaining production schedules.

ABB XDD501A101

Related model recommendations

ABB XDI501A101: A 16-channel digital input module that pairs with the ABB XDD501A101, capturing signals from sensors and switches to provide feedback to the AC 800M controller.

ABB AC800M PM864K01: The main controller that sends control signals to the ABB XDD501A101 and processes feedback from field devices.

ABB CI854A 3BSE022469R1: A PROFINET communication module that enhances the network connectivity of the ABB XDD501A101 in large-scale distributed systems.

ABB TB850 3BSE008519R1: A terminal block accessory for the ABB XDD501A101 that simplifies field wiring and provides surge protection.

ABB XDD502A101: A 32-channel digital output module with identical features to the ABB XDD501A101, suitable for larger-scale control applications.

ABB 800xA HMI: A human-machine interface that displays diagnostic data from the ABB XDD501A101 and allows operators to manually override outputs if needed.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB XDD501A101, ensure the 35mm DIN rail is securely mounted and grounded to prevent electrical noise. Verify the ambient temperature is within -25°C to 70°C and humidity is below 95% RH (non-condensing). Required tools include a torque screwdriver (0.5-0.8 Nm), wire strippers, and a multimeter. Use 16 AWG wires for power connections and ensure each channel is fused appropriately (5 A recommended). Label all connections clearly to simplify troubleshooting.

Maintenance suggestions: Inspect the ABB XDD501A101 quarterly for loose connections or dust accumulation; clean with compressed air if necessary. Check relay operation annually by activating each channel and verifying output voltage with a multimeter. Monitor diagnostic data via the AC 800M controller—address overload or open-circuit alarms immediately to prevent damage. Replace relays using ABB-approved spare parts if switching performance degrades (e.g., increased response time). Store spare modules in anti-static packaging in a dry environment (10-30°C) to maintain reliability.

Service and guarantee commitment

The ABB XDD501A101 comes with a 36-month warranty from the date of purchase, covering manufacturing defects and ensuring compliance with published specifications. ABB guarantees replacement of faulty modules within 72 hours for critical applications, minimizing operational downtime.

Technical support includes access to ABB’s global team of automation engineers, available via phone or email for configuration assistance and troubleshooting. Online resources include detailed wiring diagrams, diagnostic guides, and compatibility matrices for the AC 800M system. Customers can opt for extended service contracts offering annual preventive maintenance, firmware updates, and on-site support, ensuring the ABB XDD501A101 delivers reliable performance throughout its 10-year design lifespan.