Description

Key Technical Specifications

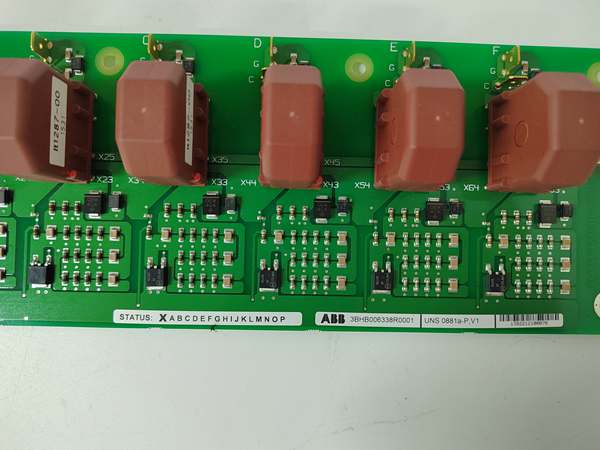

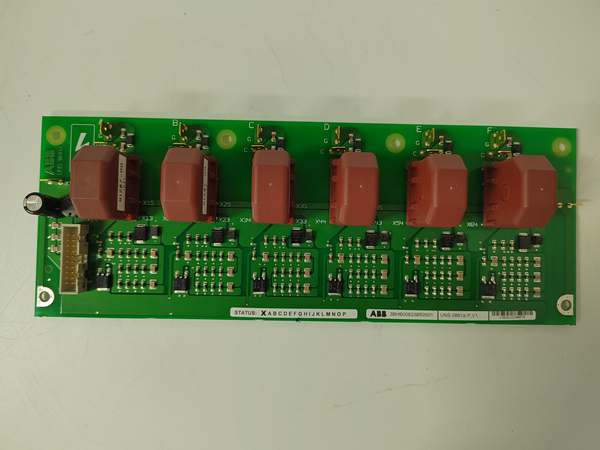

- Model Number: UNS0881a-P V1

- Manufacturer: ABB Process Automation

- Safety Rating: SIL 3 (IEC 61508), PL e (ISO 13849-1), Category 4

- Processor: 32-bit ARM Cortex-M4 safety processor (single-core, lockstep architecture)

- Memory: 1MB safety program memory, 2MB data memory, 8MB Flash storage

- Communication Interfaces: 2× Ethernet (Modbus TCP, IEC 61158), 1× RS-485 (Modbus RTU)

- Power Supply: 24VDC ±10% (redundant input, 0.3A typical current draw)

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Isolation Rating: 500V AC (power input to logic), 2kV AC (communication ports to logic)

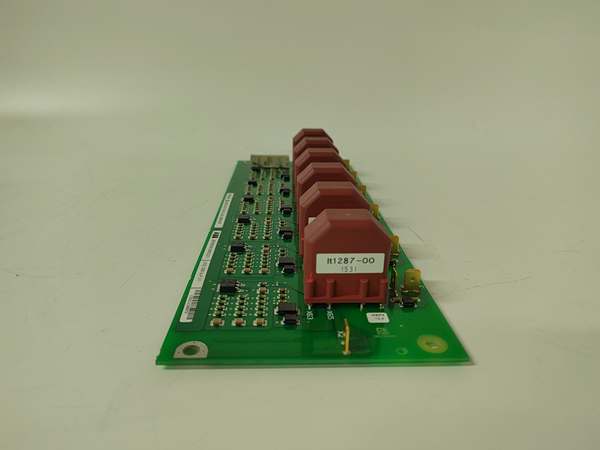

- Physical Design: DIN-rail mount, 67.5mm width, IP20 protection

- Safety Functions: Emergency stop monitoring, safety gate interlocks, two-hand control, speed monitoring

- Programming Software: Automation Builder with Safety Builder add-on

- Certifications: CE, UL 508, ATEX Zone 2, IEC 61010-1

ABB UNS0881a-P V1

Field Application & Problem Solved

In chemical plants, refineries, and packaging facilities, the biggest risk is unsafe machine or process states caused by failed safety logic—leading to equipment damage, production shutdowns, or catastrophic safety incidents. Legacy safety relays are inflexible: reconfiguring them for new safety interlocks requires rewiring, and they can’t integrate with modern SCADA systems for remote monitoring. I’ve seen a Louisiana chemical plant shut down for 3 days after a legacy safety relay failed to detect a broken safety gate interlock on a reactor—costing $2M in lost production.

You’ll find the UNS0881a-P V1 mounted in control cabinets, serving as the safety brain for critical processes: monitoring emergency stops on conveyor lines, verifying safety gate closure on mixers, and enforcing two-hand control on stamping presses. It’s a staple in industries where compliance with SIL 3/PL e is mandatory—chemical batch processing, oil refinery distillation units, and pharmaceutical manufacturing. Its core value is flexible, integrated safety logic: instead of rewiring relays, technicians reconfigure safety functions via software, cutting changeover time from days to hours. At a Pennsylvania refinery, replacing legacy relays with this module reduced safety system reconfiguration time by 90% when adding a new pump interlock.

Another unbeatable value is its native SCADA integration. Unlike standalone safety relays, it sends real-time safety status and fault data to the plant’s SCADA system via Modbus TCP—letting technicians diagnose issues remotely instead of manually checking each safety device. This saved a Michigan packaging plant 12 hours of downtime last year when a safety fault was identified and resolved from the control room.

Installation & Maintenance Pitfalls (Expert Tips)

- Lockstep Processor Calibration Is Mandatory: The module uses a lockstep processor (two identical cores running in parallel to detect errors). Rookies skip calibration during commissioning, causing “safety logic mismatch” faults that disable the safety system. Always run the lockstep calibration via Safety Builder after powering on the module for the first time—this 5-minute step prevents 90% of post-installation safety faults.

- Redundant Power Wiring Can’t Be Skimped On: The module has two power inputs for redundancy, but technicians often wire both inputs to the same power supply branch. If that branch fails, the safety CPU shuts down, triggering an unnecessary plant shutdown. Wire each power input to a separate 24VDC power supply (e.g., main and backup) to ensure true redundancy—I fixed this mistake at three different facilities last quarter.

- Safety Program Download Requires Validation: Technicians often download safety programs without running the mandatory validation check in Safety Builder. This can leave hidden logic errors (e.g., missing interlock conditions) that only surface during a safety event. Always run the “Safety Validation” tool before downloading—this catches errors like unconfigured emergency stop inputs that would otherwise cause failed safety audits.

- Shield Grounding Must Be Single-Point: RS-485 and Ethernet cables connected to the module pick up EMI if shields are grounded at both ends (creating ground loops). This causes intermittent communication faults and safety logic “glitches.” Ground the shield only at the module end—leave the device end ungrounded. A Ohio chemical plant had frequent false safety trips until shield grounding was corrected; post-fix, the system ran fault-free for 6 months.

ABB UNS0881a-P V1

Technical Deep Dive & Overview

The UNS0881a-P V1 is a single-core safety CPU module engineered for ABB’s AC500-S Safety PLC series, built to deliver SIL 3/PL e-compliant safety control in harsh industrial environments. At its core, a 32-bit ARM Cortex-M4 processor runs in lockstep architecture—two identical processing cores execute the same safety logic simultaneously, and a comparator checks for discrepancies every clock cycle. If a mismatch is detected (e.g., due to EMI or component failure), the module immediately triggers a safe state (e.g., shuts down outputs, activates alarms) within 10ms.

The module’s safety memory is write-protected to prevent unauthorized modifications—only authorized technicians with Safety Builder software can edit the safety program. It communicates with safety I/O modules (e.g., DI581-S) via the AC500-S backplane, using a proprietary safety bus that ensures low-latency data transmission (<5ms) for time-critical safety functions.

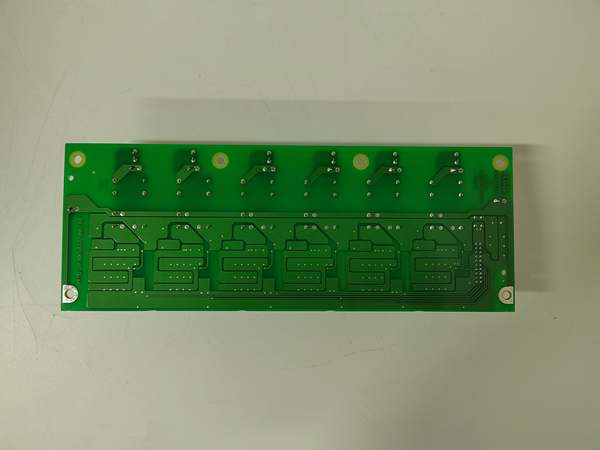

Unlike generic safety PLCs, it integrates seamlessly with ABB’s Automation Builder software—technicians program both standard and safety logic in a single environment, eliminating the need for separate tools. The module’s redundant power input and wide operating temperature range make it suitable for harsh environments, from freezing refinery control rooms to hot chemical plant cabinets. Built with industrial-grade components and conformal-coated circuit boards to resist dust and moisture, it’s rated for 15+ years of operation—making it a reliable foundation for safety-critical control systems.