Description

Detailed parameter table

| Parameter name | Parameter value |

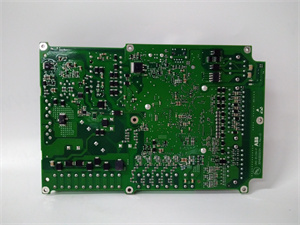

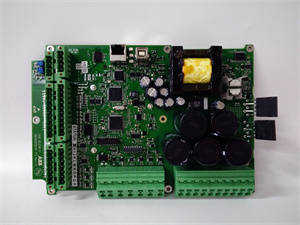

| Product model | UNS0119A-P V101 |

| Manufacturer | ABB |

| Product category | Safety controller (SafeLine series) |

| Safety rating | SIL 3 (IEC 61508), PL e (ISO 13849-1) |

| Number of safety inputs | 16 (24 VDC, PNP) |

| Number of safety outputs | 8 (24 VDC, PNP, dual-channel) |

| Communication ports | 2 x Ethernet (10/100 Mbps, PROFINET) |

| Programming language | Function Block Diagram (FBD) according to IEC 61131-3 |

| Operating voltage | 24 VDC ±15% |

| Power consumption | Max 20 W |

| Operating temperature | -10°C to 55°C |

| Protection rating | IP20 |

| Dimensions | 180mm × 120mm × 80mm |

| Weight | 0.8kg |

| Certifications | TÜV 莱茵,IEC 61508, ISO 13849-1, CE, UL |

| Mounting type | DIN rail (35mm) |

ABB UNS0119A-P V101

Product introduction

The ABB UNS0119A-P V101 is a high-performance safety controller belonging to ABB’s SafeLine series, specifically engineered to manage safety-related functions in industrial automation systems. This compact yet powerful device integrates advanced safety logic with seamless communication capabilities, making it ideal for applications where personnel and equipment protection is paramount—such as manufacturing lines, packaging machinery, and material handling systems.

As a core component in safety instrumented systems (SIS), the ABB UNS0119A-P V101 processes signals from emergency stops, light curtains, safety gates, and other safety devices, executing predefined safety logic to trigger protective actions (e.g., machine shutdowns) when hazardous conditions are detected. Its SIL 3 and PL e certifications validate its ability to operate reliably even in the most critical safety scenarios, ensuring compliance with global safety standards.

Within automation ecosystems, the ABB UNS0119A-P V101 acts as a dedicated safety layer, independent of standard control systems. This separation ensures that safety functions remain intact even if the main control system fails, providing an additional safeguard against accidents. Its PROFINET connectivity enables integration with higher-level systems for safety monitoring and diagnostics, enhancing visibility into safety events while maintaining the integrity of safety logic.

Core advantages and technical highlights

Advanced safety integrity: Certified to SIL 3 (IEC 61508) and PL e (ISO 13849-1), the ABB UNS0119A-P V101 delivers the highest level of safety performance for industrial applications. Its architecture features dual-core processing with continuous self-diagnostics, ensuring that internal faults are detected and addressed within milliseconds—preventing unsafe states. This design minimizes the probability of failure on demand (PFD), making it suitable for protecting operators around high-risk machinery like robotic welders or press brakes.

Flexible I/O configuration: With 16 safety inputs and 8 dual-channel safety outputs, the ABB UNS0119A-P V101 supports complex safety scenarios without requiring additional expansion modules. Inputs can be configured for both normally open (NO) and normally closed (NC) devices, while outputs feature built-in short-circuit and overload protection. This flexibility allows integration with diverse safety devices, from simple emergency stop buttons to advanced 3D area scanners, reducing system complexity and installation costs.

Seamless PROFINET integration: Equipped with dual PROFINET ports, the ABB UNS0119A-P V101 enables real-time communication with standard PLCs, HMIs, and safety monitoring systems. It supports safety-related data exchange via PROFIsafe, ensuring that safety signals are transmitted with guaranteed integrity and minimal latency (<10 ms). This integration allows operators to monitor safety status, reset safety functions, and log safety events from a central HMI, streamlining troubleshooting and compliance reporting.

Intuitive programming environment: The ABB UNS0119A-P V101 is programmed using ABB’s Safe Programming Suite, which employs IEC 61131-3-compliant Function Block Diagrams (FBD). The software includes a library of pre-certified safety function blocks (e.g., emergency stop, two-hand control, muting), reducing development time and ensuring logic compliance with safety standards. Program validation tools automatically check for common errors, such as incomplete safety paths, minimizing the risk of programming mistakes.

Typical application scenarios

In automotive assembly plants, the ABB UNS0119A-P V101 safeguards robotic workcells by monitoring safety gates, light curtains, and area scanners. When an operator enters the protected zone, the controller processes signals from these devices, triggering a controlled shutdown of the robot and conveyor system within 50 ms. Its PROFINET connection sends safety status updates to the plant’s MES, logging the event for compliance audits while preventing unauthorized machine restarts until the hazard is resolved.

Within packaging machinery, the ABB UNS0119A-P V101 manages safety functions for filling and sealing lines. It monitors interlock switches on access doors, emergency stops on the machine frame, and pull-wire switches along conveyor paths. The controller’s logic ensures that all motion stops before access doors can be opened, while allowing temporary muting of light curtains during product changeovers—maintaining safety without sacrificing productivity.

In logistics automation, such as palletizing systems, the ABB UNS0119A-P V101 protects operators from moving robotic arms by integrating with safety laser scanners. It processes scanner data to detect operator presence in the robot’s working envelope, slowing or stopping the robot based on proximity. Dual-channel outputs ensure that even a single output failure won’t prevent the safety action, while PROFINET connectivity allows remote monitoring of safety events for predictive maintenance.

ABB UNS0119A-P V101

Related model recommendations

ABB UNS0219A-P V101: A scalable variant of the ABB UNS0119A-P V101 with 32 safety inputs and 16 outputs, designed for larger safety systems.

ABB 2TLA020074R0000: An emergency stop button with a twist-to-release function, directly compatible with the inputs of the ABB UNS0119A-P V101.

ABB MSR127: A safety relay module that complements the ABB UNS0119A-P V101 by providing additional output channels for large-scale machinery.

ABB Safe Programming Suite: Software used to configure and validate safety logic for the ABB UNS0119A-P V101, including a library of certified function blocks.

ABB CP600 HMI: A human-machine interface that displays safety status and allows resetting of safety functions via the ABB UNS0119A-P V101‘s PROFINET connection.

ABB TB520: A terminal block with surge protection, simplifying wiring for the ABB UNS0119A-P V101 and ensuring reliable connections to field devices.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB UNS0119A-P V101, ensure the 35mm DIN rail is securely mounted in a grounded control cabinet, away from sources of electromagnetic interference (e.g., motor drives). Verify the ambient temperature is within -10°C to 55°C and humidity is below 90% RH (non-condensing). Required tools include a torque screwdriver (0.5-0.8 Nm), wire strippers, and a multimeter. Use shielded twisted-pair cables (0.5-1.5 mm²) for all safety connections, with shields grounded at both ends to minimize noise.

Maintenance suggestions: Inspect the ABB UNS0119A-P V101 quarterly for loose connections, dust accumulation, or signs of overheating; clean with compressed air if necessary. Perform monthly functional tests by activating each safety input (e.g., pressing emergency stops) and verifying the corresponding output action. Check the controller’s status LED—steady green indicates normal operation, while red or flashing LEDs signal faults requiring immediate attention. Back up the safety program to a secure location whenever changes are made. Replace the controller only with an ABB-approved unit to maintain safety certifications.

Service and guarantee commitment

The ABB UNS0119A-P V101 is backed by a 5-year warranty from the date of installation, covering manufacturing defects and ensuring compliance with safety certifications. ABB guarantees that any unit failing to meet safety standards during this period will be replaced within 48 hours, minimizing downtime in safety-critical systems.

Technical support includes access to ABB’s global team of safety specialists, available for assistance with logic programming, risk assessments, and compliance documentation. Online resources include certified safety manuals, programming guides, and firmware updates specific to the ABB UNS0119A-P V101. Customers can opt for extended service contracts offering annual safety audits, functional safety assessments, and on-site support, ensuring the controller maintains its safety integrity throughout its 15-year design lifespan.