Description

Detailed parameter table

| Parameter name | Parameter value |

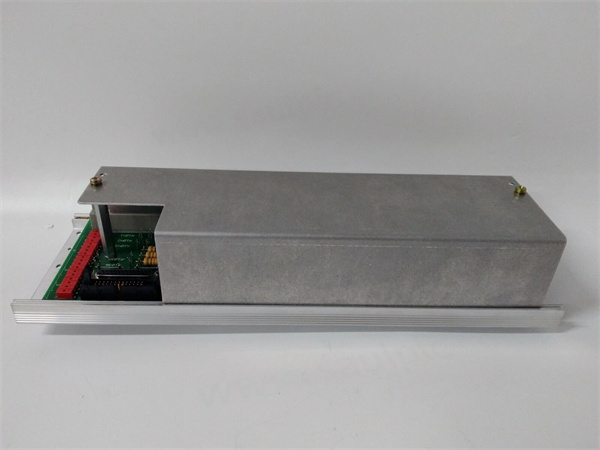

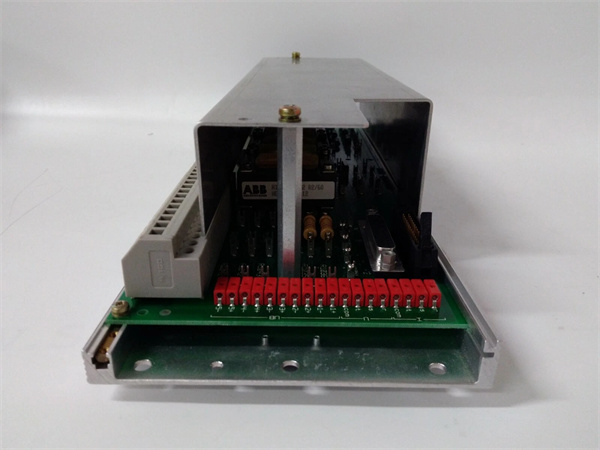

| Product model | UNC4672AV1 HIEE205012R1 |

| Manufacturer | ABB |

| Product category | Safety control module |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Performance level | PL e (per ISO 13849-1) |

| Number of safety inputs | 16 dual-channel safety inputs |

| Number of safety outputs | 8 safety outputs (PNP) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 8 W |

| Response time | <10 ms |

| Isolation | 5 kV AC (channels to backplane) |

| Operating temperature | -25°C to 70°C |

| Dimensions | 120mm × 180mm × 90mm |

| Mounting type | Backplane mount (compatible with AC500-S safety controllers) |

| Protection rating | IP20 |

| Certifications | IEC 61508, ISO 13849-1, CE, UL, ATEX |

ABB UNC4672AV1 HIEE205012R1

Product introduction

The ABB UNC4672AV1 HIEE205012R1 is a high-integrity safety control module designed to monitor and execute safety-critical functions in industrial automation systems. As a core component in ABB’s safety automation portfolio, ABB UNC4672AV1 HIEE205012R1 provides redundant safety input/output capabilities, ensuring reliable detection and response to hazardous conditions in applications where human safety and equipment protection are paramount.

ABB UNC4672AV1 HIEE205012R1 is certified for SIL 3 and PL e, making it suitable for the most demanding safety applications, including emergency stop circuits, safety interlocks, and machinery guarding. Its dual-channel design for inputs and fail-safe architecture ensure that single faults cannot compromise system safety, while its seamless integration with ABB’s AC500-S safety controllers and communication modules like the CI627A enables coordinated safety control across complex industrial networks. Whether deployed in automotive manufacturing, process industries, or material handling, ABB UNC4672AV1 HIEE205012R1 forms a critical layer of protection, preventing accidents and minimizing downtime from safety-related shutdowns.

Core advantages and technical highlights

SIL 3/PL e certification: ABB UNC4672AV1 HIEE205012R1 meets the highest safety standards, ensuring it can be trusted in applications where failure could result in severe injury or loss of life. Its certification to IEC 61508 (SIL 3) and ISO 13849-1 (PL e) confirms that it achieves a probability of dangerous failure per hour (PFHd) of less than 10⁻⁹, making it suitable for protecting robotic workcells, press machines, and other high-risk equipment. In an automotive stamping plant, this certification ensures that the module reliably triggers a stop when a safety light curtain is breached, preventing crush injuries.

Dual-channel redundancy: The module’s 16 safety inputs are configured as 8 dual-channel pairs, with each input signal monitored by two independent circuits. This redundancy ensures that a fault in one channel (e.g., a broken wire or sensor failure) is detected, and the module enters a safe state without triggering an unnecessary shutdown. For example, in a packaging machine with dual emergency stop buttons, the module verifies that both buttons (wired to separate channels) are activated before initiating a shutdown, preventing false trips from a single faulty button.

Fast response time: With a response time of less than 10 ms, ABB UNC4672AV1 HIEE205012R1 ensures rapid reaction to safety events. In a high-speed bottling line, this speed means that a jam detected by safety sensors triggers an immediate stop, preventing bottles from shattering and creating a hazard for operators. The module’s fast processing also allows for precise synchronization of safety functions across multiple machines, ensuring coordinated shutdowns in interconnected production lines.

Robust isolation and fault detection: Equipped with 5 kV AC isolation between channels and the backplane, ABB UNC4672AV1 HIEE205012R1 is immune to electrical noise and ground loops, critical in industrial environments with high-power equipment. Its continuous self-monitoring checks for internal faults (e.g., CPU errors, power supply issues) and external faults (e.g., short circuits, open circuits), logging diagnostic data and entering a safe state if a fault is detected. This self-diagnostics capability reduces troubleshooting time, as maintenance teams can quickly identify whether a safety shutdown was caused by a genuine hazard or a system fault.

Typical application scenarios

In a chemical processing plant, ABB UNC4672AV1 HIEE205012R1 is integrated into the safety instrumented system (SIS) protecting a reactor vessel. It monitors 16 safety inputs, including pressure relief valve status, temperature high-limit sensors, and emergency stop buttons from the control room and field stations. The module’s 8 safety outputs control shutdown valves and isolate the reactor in case of overpressure or overtemperature. Its SIL 3 certification ensures compliance with process safety standards (IEC 61511), while its communication with the AC500-S controller via the CI627A module enables logging of safety events for regulatory reporting.

In a warehouse automated storage and retrieval system (AS/RS), ABB UNC4672AV1 HIEE205012R1 monitors safety laser scanners and access door interlocks. When a scanner detects a pedestrian in the robot’s path, the module triggers a safe stop of the automated crane within 10 ms, preventing collisions. Its dual-channel inputs ensure that a scanner malfunction is detected, and a diagnostic alarm is sent to the XVC517AE10 HMI without stopping the entire system—minimizing disruption to warehouse operations. The module’s wide temperature range allows reliable operation in the unheated warehouse environment.

ABB UNC4672AV1 HIEE205012R1

Related model recommendations

ABB AC500-S Safety PLC: The safety controller that pairs with ABB UNC4672AV1 HIEE205012R1 to execute safety logic and coordinate safety functions.

ABB CI627A 3BSE017457R1: A communication module that enables ABB UNC4672AV1 HIEE205012R1 to transmit safety status data to non-safety systems.

ABB XVC517AE10 3BHB004744R0010: An HMI that displays safety alarms and diagnostic data from ABB UNC4672AV1 HIEE205012R1.

ABB RXIDK 2H 1MRK000838-HA: A digital input module that complements ABB UNC4672AV1 HIEE205012R1 for non-safety signal monitoring.

ABB PPE091A101 3BHE044481R0101: A redundant 24 V DC power supply ensuring uninterrupted operation of ABB UNC4672AV1 HIEE205012R1.

ABB TB857: A surge protection terminal block that shields ABB UNC4672AV1 HIEE205012R1 inputs from voltage transients in industrial environments.

Installation, commissioning and maintenance instructions

Installation preparation: Mount ABB UNC4672AV1 HIEE205012R1 into the AC500-S backplane, ensuring proper alignment with connector pins. Torque the retaining screw to 0.5 Nm. Connect safety inputs (e.g., emergency stops, light curtains) to the dual-channel terminals using 0.5mm² shielded twisted-pair cable, with separate runs for each channel to prevent common-mode faults. Wire safety outputs to contactors or valves using 0.75mm² cable, ensuring the load is within the 2A per output rating. Power the module via the backplane 24 V DC supply, protected by a 1A fuse. Use a torque screwdriver set to 0.5 Nm for terminal connections. Power off the system during installation and follow lockout/tagout procedures.

Maintenance suggestions: Inspect ABB UNC4672AV1 HIEE205012R1 quarterly for loose connections, dust accumulation, and LED status (power: green, safe state: steady yellow, fault: red). Clean ventilation slots with compressed air. Test safety functions semi-annually by simulating hazardous conditions (e.g., activating emergency stops) and verifying that outputs respond within 10 ms. Perform a full functional safety assessment annually, including verification of SIL 3 compliance using ABB’s safety test software. If faults are detected, replace the module with an ABB-certified unit—never attempt to repair safety-critical components.

Service and guarantee commitment

ABB UNC4672AV1 HIEE205012R1 is backed by a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with safety certifications (SIL 3, PL e). ABB’s safety-certified technical support team provides response within 2 hours for critical issues, with remote diagnostics available 24/7 to minimize downtime in safety-critical systems. On-site service is available within 48 hours in major industrial regions for complex commissioning or troubleshooting.

The warranty includes access to safety manual updates, configuration tools, and certification documentation. Extended service contracts offer annual safety audits, functional testing, and priority support, ensuring the module maintains its safety integrity throughout its 15-year design lifespan. ABB’s commitment to safety underscores confidence in ABB UNC4672AV1 HIEE205012R1 as a reliable protector of workers and equipment in high-risk environments.