Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | UFC911B106 3BHE037864R0106 |

| Manufacturer | ABB |

| Product Category | Redundant Controller System |

| Processor Configuration | Dual PM865 controllers (1:1 redundancy) |

| Processor Speed | Dual-core PowerPC @ 1.3 GHz each |

| Memory | 2 GB RAM / 4 GB Flash per controller |

| Sync Interface | Fiber-optic redundancy link (100 Mbps) |

| Failover Time | < 10 ms |

| Power Supply | Dual 24V DC inputs (18-30V DC range) |

| Safety Certification | SIL 3 (IEC 61508), TÜV certified |

| Operating Temperature | -40°C to +70°C |

| Vibration Resistance | 2.5 g (5-150 Hz) |

| MTBF | > 750,000 hours |

UFC911B106 3BHE037864R0106

Product Introduction

The ABB UFC911B106 3BHE037864R0106 represents ABB’s premium fault-tolerant control solution, integrating dual PM865 controllers into a unified high-availability system. Designed for continuous process industries where downtime is unacceptable, this redundant configuration forms the nucleus of ABB’s Extended Automation System 800xA. The UFC911B106 3BHE037864R0106 delivers seamless control transition during hardware failures through its synchronized dual-processor architecture, maintaining uninterrupted operation of critical processes.

This integrated system executes complex regulatory control, safety instrumented functions (SIF), and sequential operations across demanding environments like refineries and power generation. The redundant pair of 3BHE037864R0106 controllers operate in active/standby mode with continuous memory synchronization, ensuring zero data loss during switchovers. The ABB UFC911B106 3BHE037864R0106 extends ABB’s automation leadership by combining computational power with fault tolerance for the most rigorous industrial applications.

Core Advantages and Technical Highlights

Continuous Process Integrity:

The ABB UFC911B106 3BHE037864R0106 achieves <10ms failover through hardware-synchronized fiber-optic links. Both controllers execute identical instruction sets simultaneously, with automatic voter logic detecting discrepancies and initiating transparent controller switchover without process interruption.

Cybersecurity Integration:

Features TPM 2.0 hardware encryption on both controllers with synchronized key management. Implements secure boot chains and runtime integrity checking that meet IEC 62443-3-3 SL2 requirements, providing coordinated protection against cyber threats.

Deterministic Performance Under Stress:

Maintains 10ms control loop execution during maximum I/O load (12,000 points) and communication traffic. Dedicated redundancy management processors offload synchronization tasks from main CPUs, ensuring consistent performance during disturbance events.

Environmental Hardening:

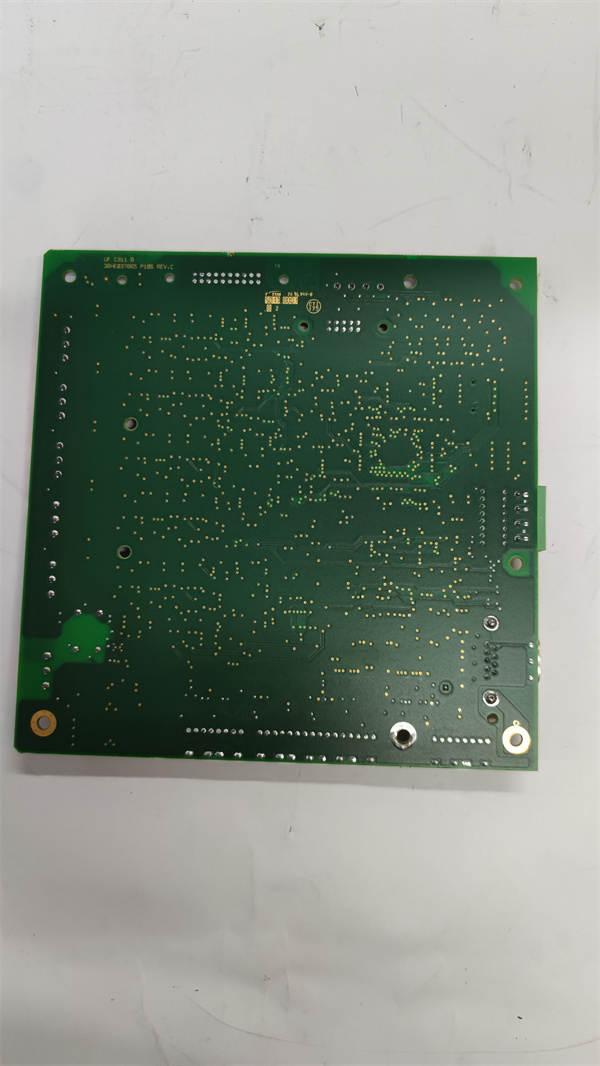

Operates at full performance from -40°C Arctic conditions to +70°C desert environments. Conformal-coated PCBs and hermetically sealed fiber interfaces withstand 95% non-condensing humidity and corrosive atmospheres.

Typical Application Scenarios

In offshore oil platforms, the ABB UFC911B106 3BHE037864R0106 manages subsea safety valves and compressor control while surviving salt spray exposure and platform vibration. Its dual-controller design prevents single-point failures during hurricane-induced power fluctuations that could trigger catastrophic releases.

Nuclear power plants utilize this system for reactor coolant pump control, where the SIL 3-certified pair executes diverse voting logic for neutron flux monitoring. The fiber-optic isolation between controllers prevents electromagnetic pulse (EMP) interference from disrupting both units simultaneously. For pharmaceutical continuous manufacturing, the UFC911B106 3BHE037864R0106 maintains sterility control during tablet compression, with automatic controller switchover during utility power transfers avoiding batch rejection.

UFC911B106 3BHE037864R0106

Related Model Recommendations

TA526 Redundancy Kit: Fiber-optic synchronization package

SD833 Power Supply: Dual-input 24V DC source

PM866 Redundant Set: Higher-speed quad-core controller pair

CI867 IEC 61850 Module: Grid protection communication

CP635-TC HMI: Tactile control panel for local access

S800 I/O with TB820: Redundant field signal interface

COM625 Security Appliance: Network protection gateway

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Mount controller rack vertically with seismic bracing in high-vibration areas. Ensure independent power feeds from different substations for true redundancy. Verify <0.5Ω earth bonding before fiber-optic cable installation. Use ABB-specified LC connectors for synchronization links.

Maintenance Recommendations:

Monthly verify redundancy synchronization via Control Builder M diagnostics. Annually clean fiber-optic transceivers with approved toolkit. Replace both controllers simultaneously during lifecycle upgrades to maintain firmware compatibility. Monitor “Sync Deviation” parameter – values >5µs indicate need for fiber inspection. Always maintain identical firmware revisions on paired UFC911B106 3BHE037864R0106 controllers.

Service and Guarantee Commitment

ABB provides a 60-month warranty for the UFC911B106 3BHE037864R0106, including priority 4-hour response for critical failure events. Redundancy assurance program guarantees <15min remote diagnostics resolution for synchronization issues. Lifecycle commitment ensures hardware availability for 20 years post-manufacturing, with firmware support extending 5 years beyond hardware discontinuation.

All systems undergo 1,000-hour accelerated lifecycle testing including 500 thermal shock cycles (-40°C ↔ +85°C) and 72-hour burn-in at maximum I/O load. SIL recertification services include full diagnostic coverage verification and cybersecurity penetration testing compliant with IEC 61511 and NERC CIP standards.