Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | UFC911B101 |

| Manufacturer | ABB |

| Product Category | Field Control Module |

| Input Voltage | 24V DC (±15%) |

| Power Consumption | 7W typical |

| Processor | 32-bit RISC (200MHz) |

| Memory | 64MB Flash, 32MB RAM |

| Communication Ports | 2x Ethernet, 1x RS-485 |

| Protocols Supported | Modbus TCP/RTU, PROFIBUS DP |

| Operating Temperature | -25°C to +70°C |

| Protection Class | IP20 |

| Dimensions | 120 × 100 × 75 mm |

| Weight | 450g |

| Compliance Standards | IEC 61131-2, UL 508 |

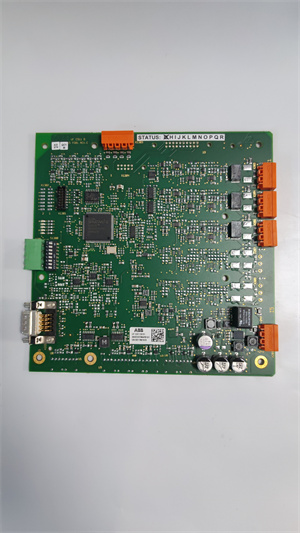

ABB UFC911B101

Product Introduction

The ABB UFC911B101 is a high-performance field control module designed for industrial automation applications requiring reliable local control and data processing. Part of ABB’s S800 I/O system, this versatile module serves as an intelligent interface between field devices and higher-level control systems in demanding industrial environments.

The UFC911B101 combines robust industrial computing power with flexible I/O expansion capabilities, making it ideal for distributed control applications in process industries and discrete manufacturing. Its compact design and DIN rail mounting allow for space-efficient installation in control cabinets, while the wide operating temperature range enables deployment in harsh environments.

Core Advantages and Technical Highlights

Computational performance: The ABB UFC911B101 features a powerful 32-bit RISC processor running at 200MHz, capable of executing complex control algorithms locally. With 64MB of flash memory and 32MB RAM, the module can store and process substantial amounts of process data, reducing the load on central controllers.

Communication flexibility: Dual Ethernet ports support Modbus TCP/IP communication, while the integrated RS-485 interface enables Modbus RTU and PROFIBUS DP connectivity. The UFC911B101 can function as a protocol converter, bridging between different fieldbus systems and Ethernet-based control networks.

Robust industrial design: Engineered for reliability, the module features:

Industrial-grade components rated for continuous operation

Conformal coated PCB for protection against humidity and contaminants

1.5kV isolation on communication ports

Surge protection on power inputs

Advanced diagnostics: The UFC911B101 provides comprehensive system monitoring capabilities including:

Continuous health monitoring of connected I/O modules

Detailed event logging with timestamp

Watchdog timer for automatic recovery

LED status indicators for quick troubleshooting

ABB UFC911B101

Typical Application Scenarios

The ABB UFC911B101 is widely deployed in industrial automation systems:

Process Industries:

Local control of pump stations in water treatment plants

Interface module for field instruments in oil & gas pipelines

Data concentrator for batch processes in chemical plants

Manufacturing:

Machine control in automotive production lines

Data acquisition system for quality monitoring

Protocol converter for legacy equipment integration

Energy Management:

Substation automation controller

Power monitoring system interface

Renewable energy plant controller

Related Model Recommendations

UFC921B101: Enhanced version with additional communication ports

UFC911A101: Basic version with reduced memory

UFC931B101: High-performance model with dual-core processor

UFC941B101: Safety-rated version for SIL2 applications

UFC951B101: Advanced model with integrated web server

S800 I/O modules: Compatible digital/analog I/O cards

CI854: Communication interface module

Installation, Commissioning and Maintenance Instructions

Installation preparation:

Verify power supply compatibility (24V DC ±15%)

Prepare DIN rail mounting space (minimum 50mm clearance)

Ensure proper grounding of control cabinet

Have appropriate communication cables ready

Commissioning steps:

Install module on DIN rail

Connect power and communication cables

Configure network parameters

Load application program

Test communication with connected devices

Maintenance recommendations:

Annual inspection of terminal connections

Periodic firmware updates

Regular backup of configuration files

Monitoring of module temperature

Replacement every 10 years or as indicated by diagnostics

Service and Guarantee Commitment

ABB provides:

36-month standard warranty

Extended warranty options available

Global technical support network

Online knowledge base and documentation

Firmware update service

Repair and replacement services

On-site support contracts

The UFC911B101 undergoes rigorous testing including:

1000-hour burn-in test

Environmental stress screening

EMC immunity testing

Mechanical vibration testing