Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

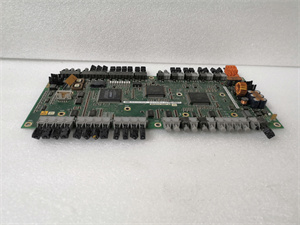

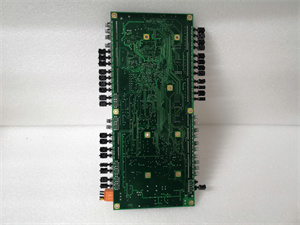

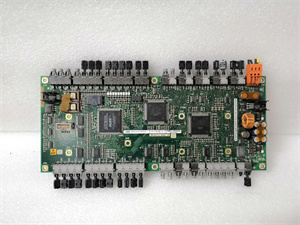

| Product Model | UFC760BE42 (3BHE004573R0042) |

| Manufacturer | ABB |

| Product Category | PROFINET Controller Module |

| Bus Protocol | PROFINET IRT Class C (IEC 61158) |

| Data Transfer Rate | 100 Mbps (Full-duplex Ethernet) |

| Port Configuration | 3x RJ45 (2x PORTS, 1x OLM) |

| Cycle Time | ≤250 μs (deterministic) |

| I/O Capacity | Up to 512 devices per controller |

| Power Supply | 24 VDC (19.2–28.8 V) |

| Operating Temperature | -25°C to +70°C |

| Certifications | SIL 3 (IEC 61508), UL/cUL, CE, DNV GL |

| Redundancy | MRP (Media Redundancy Protocol) |

| Integration | ABB AC 800M/800xA/Symphony Plus |

| Safety Functions | PROFIsafe (IEC 61784-3-3) |

ABB UFC760BE42 3BHE004573R0042

Product Introduction

The ABB UFC760BE42 (3BHE004573R0042) serves as a high-performance PROFINET controller module within ABB’s S800 I/O ecosystem, engineered for real-time industrial automation. This non-redundant module enables deterministic communication between AC 800M controllers and PROFINET-enabled field devices such as drives, remote I/O, and robotic systems. The ABB UFC760BE42 supports PROFINET IRT (Isochronous Real-Time) Class C, delivering synchronized data exchange with ≤250 μs cycle times for motion-critical applications.

Integrated with ABB’s 800xA DCS and Symphony Plus platforms, this module provides seamless configuration through Control Builder M engineering tools. Its triple-port architecture allows daisy-chain, star, or ring topologies via integrated optical link media (OLM) support. For industries requiring functional safety, the ABB UFC760BE42 achieves SIL 3 certification and implements PROFIsafe protocols for safety-critical I/O handling.

Core Advantages and Technical Highlights

Real-time precision: Hardware-based PROFINET ASIC achieves jitter-free ≤250 μs cycle times, enabling synchronized multi-axis robotics and high-speed packaging lines. Supports “Shared Device” functionality for multi-controller access.

Functional safety integration: Native PROFIsafe implementation (up to SIL 3) allows safety I/O integration without additional gateways. Dual-channel diagnostics validate signal integrity for emergency stop circuits.

Network resilience: Integrated Media Redundancy Protocol (MRP) manager enables <20ms ring recovery. The optical port (BFOC) supports fiber-optic connections up to 3 km, eliminating ground loops in electrically noisy environments.

Engineering efficiency: Automatic device replacement (ADR) stores device configurations internally, reducing replacement downtime by 90%. Drag-and-drop device commissioning in Control Builder M.

Cybersecurity hardened: Supports VLAN tagging (IEEE 802.1Q) and port security (MAC lockdown). Hardware TPM for encrypted firmware validation.

Typical Application Scenarios

In automotive body shops, the ABB UFC760BE42 synchronizes robotic welding cells via PROFINET IRT, coordinating 32-axis systems with ±1ms timing precision. Its SIL 3 capability integrates laser scanner safety curtains directly into the control logic.

Pharmaceutical filling lines leverage the module’s deterministic control for servo-driven vial handling, where ≤250μs cycle times ensure precise fill-volume accuracy. OLM fiber connections prevent EMI interference from variable frequency drives.

Offshore wind farms deploy the UFC760BE42 for turbine pitch control, utilizing PROFIsafe to manage hydraulic braking systems. The -25°C cold-start capability ensures operation in Arctic environments, while DNV GL certification meets maritime standards.

ABB UFC760BE42 3BHE004573R0042

Related Model Recommendations

UFC762BE42: Redundant PROFINET controller version

CI871: PROFINET I/O scanner for AC 800M

TB811: 16-slot S800 I/O baseplate

SD826: 64GB industrial SD card for device configuration storage

PP885: Touch panel HMI with PROFINET integration

SA801F: Safety controller for SIL 3 interlocking

PFEA201: Fiber-optic media converter (M12 to BFOC)

3BSE050091R25 PPC902AE: Process control panel

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount the UFC760BE42 horizontally on S800 baseplate (slot 0 required). Use CAT6A shielded Ethernet cables with 360° grounding clamps. Maintain bend radius >50mm for fiber-optic connections. Verify electrical isolation (500V DC) between network segments.

Maintenance suggestions: Monitor “Cycle Time Deviation” monthly via Diagnostics Manager; >5μs variance requires topology optimization. Replace internal backup battery every 5 years. Clean optical ports quarterly with anhydrous ethanol. Always de-energize before module extraction.

Service and Guarantee Commitment

ABB provides a 36-month warranty for UFC760BE42 (3BHE004573R0042), including firmware updates with cybersecurity enhancements. Global technical support offers PROFINET conformance testing through ABB’s Automation Sentinel program. Lifetime product support guarantees spare parts for 15 years post-discontinuation. All modules undergo 168-hour HALT testing (-40°C to +85°C thermal cycling) and 10,000+ plug cycles on connectors. SIL certification includes TÜV Nord validation documentation.