Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | UFC719AE01 |

| Manufacturer | ABB |

| Product category | Analog/Digital I/O Card |

| Number of inputs/outputs | 32 digital inputs, 32 digital outputs |

| Input/output type | Digital input signal: DC 24V; Digital output signal: DC 24V |

| Input/output current | Digital input current ≤ 7mA; Digital output current ≤ 500mA |

| Input/output voltage | Digital input voltage range: DC 0 – 30V; Digital output voltage range: DC 0 – 30V |

| Input/output response time | Digital input signal response time ≤ 1ms; Digital output signal response time ≤ 1ms |

| High – speed counter input | Supports 4 high – speed counter inputs, maximum input frequency 100kHz |

| Operating temperature range | – 25℃ ~ + 70℃ |

| Power supply voltage | DC 24V |

| Power consumption | Maximum power consumption 6W |

| Dimensions (height x width x depth) | 130 mm x 35 mm x 130 mm |

| Weight | About 0.3 kg |

| Communication interface | RS485 serial interface |

| Communication protocol | Modbus RTU |

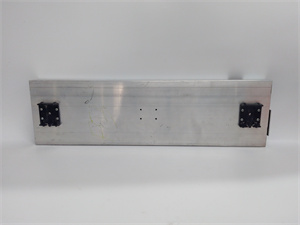

ABB UFC719AE01

Product introduction

The ABB UFC719AE01 is a highly versatile and reliable Analog/Digital I/O Card, designed to meet the rigorous demands of industrial control systems. As a part of ABB’s extensive range of industrial automation products, this card plays a pivotal role in facilitating seamless communication between field devices and control systems.

With its ability to handle a significant number of digital inputs and outputs, the UFC719AE01 can efficiently interface with various sensors, actuators, and other digital devices in an industrial setup. The high – speed counter inputs are particularly useful for applications that require accurate counting of pulses, such as in motion control systems or conveyor belt monitoring. In the context of industrial automation, this card serves as a crucial link, ensuring that real – time data from the field is accurately transmitted to the control system, and control commands are effectively relayed back to the actuators.

Core advantages and technical highlights

High – density I/O configuration: The ABB UFC719AE01 offers an impressive 32 digital inputs and 32 digital outputs. This high – density configuration allows for the connection of a large number of devices in a single module, reducing the need for multiple cards and thus saving valuable space in control cabinets. In a large – scale manufacturing plant with numerous sensors and actuators, this feature enables a more compact and cost – effective control system setup.

Fast response times: With input and output response times of ≤ 1ms, the card is well – suited for applications that demand rapid data transfer and control actions. In a high – speed packaging line, for example, where split – second decisions need to be made based on sensor inputs, the UFC719AE01 can quickly process the data and trigger the appropriate output signals, ensuring smooth and efficient operation.

High – speed counter support: The support for 4 high – speed counter inputs with a maximum frequency of 100kHz makes the ABB UFC719AE01 ideal for applications involving precise motion control and counting. In a printing press, these high – speed counters can accurately measure the speed of the printing rollers and adjust the printing process accordingly, resulting in high – quality prints.

Wide temperature range operation: Being able to operate in temperatures ranging from – 25℃ to + 70℃, the UFC719AE01 can be deployed in a variety of harsh industrial environments. Whether it’s in a cold storage facility or a hot and humid manufacturing plant, this card can maintain its performance, ensuring continuous operation of the control system.

Typical application scenarios

Manufacturing industry: In an automotive assembly line, the ABB UFC719AE01 can be used to interface with proximity sensors, limit switches, and pneumatic valves. The digital inputs can receive signals from the sensors to detect the position of car parts on the conveyor belt, while the digital outputs can control the valves to operate robotic arms for precise assembly tasks. The high – speed counter inputs can be used to measure the speed of the conveyor belt, ensuring that the assembly process runs smoothly.

Water and wastewater treatment plants: Here, the UFC719AE01 can be connected to level sensors, flow meters, and pumps. The digital inputs will receive data from the sensors regarding the water level and flow rate, and based on this information, the digital outputs can control the pumps to maintain proper water flow and treatment processes. The wide temperature range of the card makes it suitable for use in both indoor and outdoor installations within the treatment plant.

Food and beverage production: In a bottling plant, the ABB UFC719AE01 can be used to control the filling and capping machines. The digital inputs can detect the presence of empty bottles, while the digital outputs can control the filling valves and capping mechanisms. The fast response times of the card are crucial in ensuring that the bottling process is accurate and efficient, minimizing product waste.

ABB UFC719AE01

Related model recommendations

UFC720AE01: A more advanced version of the UFC719AE01, with additional communication interfaces such as Ethernet. This model is suitable for applications that require high – speed data transfer over a network, like in large – scale industrial complexes where real – time data monitoring and control are crucial.

UFC715AE01: A lower – cost alternative with a reduced number of I/O channels. It is ideal for small – scale industrial applications or for those on a tight budget, where the full functionality of the UFC719AE01 is not required.

AI810F: An analog input module by ABB that can be used in conjunction with the UFC719AE01 in applications where both analog and digital inputs are needed. For example, in a chemical plant where temperature and pressure sensors (analog) and switch – type sensors (digital) are used for process control.

DO820F: A digital output module which can be paired with the UFC719AE01 when additional digital outputs are required. In a lighting control system for a large factory, the UFC719AE01 can handle the input signals, and the DO820F can be used to control a larger number of lighting fixtures.

RDCU – 12C: A drive control unit that can work in harmony with the UFC719AE01 in motor – control applications. The UFC719AE01 can provide the control signals, and the RDCU – 12C can regulate the speed and torque of the motors.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB UFC719AE01, ensure that the control cabinet is clean, dry, and well – ventilated. The ambient temperature should be within the specified operating range of – 25℃ to + 70℃. Use appropriate ESD – safe tools and follow anti – static procedures to prevent damage to the sensitive components on the card. Mount the card securely on the DIN rail or the designated mounting surface in the control cabinet. Check the wiring connections carefully before powering on the system.

Maintenance suggestions: Regularly inspect the UFC719AE01 for any signs of physical damage, such as bent pins or discolored components. Clean the card periodically using compressed air to remove dust and debris, which can affect its performance. Monitor the input and output signals to ensure they are within the expected range. In case of a malfunction, check the error codes (if available) and refer to the product manual for troubleshooting steps. If a component needs to be replaced, use only genuine ABB spare parts to maintain the integrity and performance of the card.

Service and guarantee commitment

ABB offers a comprehensive service and guarantee commitment for the UFC719AE01. The product comes with a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. ABB’s global network of service centers provides prompt technical support, whether it’s for installation guidance, troubleshooting, or advice on optimizing the card’s performance. In case of a product failure, ABB ensures fast replacement or repair services to minimize downtime. Additionally, ABB offers training programs for customers to familiarize themselves with the product, enabling them to make the most of its features and capabilities.