Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | UAD154A 3BHE026866R0101 |

| Manufacturer | ABB |

| Product category | Analog input module for process automation |

| Input channels | 8 (isolated, configurable) |

| Input signal types | 4-20 mA, 0-20 mA, 0-10 V DC, thermocouple (J/K/T/E/R/S/B), RTD (Pt100, Ni100) |

| Measurement accuracy | ±0.05% FS (for 4-20 mA), ±0.1°C (for thermocouple) |

| Sampling rate | 10 Hz per channel (simultaneous) |

| Isolation | Channel-to-channel: 2.5 kV AC; Channel-to-backplane: 5 kV AC |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 8 W |

| Operating temperature | -40°C to 70°C |

| Protection rating | IP20 |

| Mounting type | Backplane mount (AC800M/DCS800 series) |

| Dimensions | 100mm × 160mm × 80mm |

| Certifications | CE, UL, ATEX, IEC 61131-2, IEC 61010-1 |

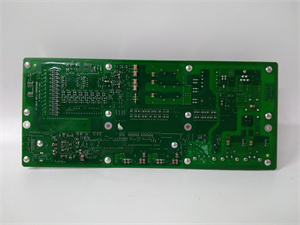

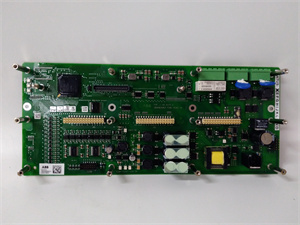

ABB UAD154A 3BHE026866R0101

Product introduction

The UAD154A 3BHE026866R0101 is a high-precision analog input module from ABB, engineered to convert and process diverse sensor signals in industrial automation systems. As a critical component in ABB’s process measurement portfolio, UAD154A 3BHE026866R0101 serves as the interface between field devices (such as temperature sensors, pressure transmitters, and force sensors like the PFTL201C 3BSE007913R50 50KN) and control systems like the 500CPU05 1MRB150081R1/E PLC.

This 8-channel module supports a wide range of input signals, eliminating the need for multiple specialized modules in complex process environments. Unlike basic analog cards, UAD154A 3BHE026866R0101 features advanced signal conditioning and high isolation, ensuring accurate data acquisition even in noisy industrial settings. Whether deployed in chemical plants, power generation facilities, or manufacturing lines, UAD154A 3BHE026866R0101 provides reliable, high-fidelity data to drive process control and optimization.

Core advantages and technical highlights

Multi-signal flexibility: UAD154A 3BHE026866R0101’s 8 channels can be individually configured for 4-20 mA, thermocouple, RTD, or voltage signals—all without hardware modifications. In a chemical reactor system, this allows the module to simultaneously measure temperature (via thermocouple), pressure (4-20 mA), level (0-10 V), and flow (4-20 mA) using a single module, reducing backplane space by up to 60% compared to single-type input cards.

Exceptional measurement accuracy: With ±0.05% full-scale accuracy for 4-20 mA signals and ±0.1°C for thermocouples, UAD154A 3BHE026866R0101 ensures precise data for critical processes. In pharmaceutical batch production, this accuracy enables tight control of reaction temperatures, ensuring compliance with FDA regulations. The module’s low drift (<50 ppm/°C) maintains stability even in temperature-fluctuating environments, such as near industrial ovens or cold storage zones.

Robust noise immunity: UAD154A 3BHE026866R0101 features 2.5 kV channel-to-channel isolation and 5 kV isolation from the backplane, preventing ground loops and electromagnetic interference (EMI) from motors or variable frequency drives. In steel mills, where electrical noise is prevalent, this isolation ensures accurate force measurements from PFTL201C 3BSE007913R50 50KN sensors despite nearby high-voltage equipment.

Wide operating range: The module operates reliably from -40°C to 70°C, making it suitable for extreme environments—from arctic oil rigs to desert solar power plants. Its extended temperature tolerance eliminates the need for climate-controlled enclosures in remote installations, reducing infrastructure costs.

Seamless system integration: UAD154A 3BHE026866R0101 integrates with ABB’s AC800M DCS and 500CPU05 PLCs via a high-speed backplane, with data available to the controller in <100 ms. It supports hot swapping, allowing replacement without system shutdown—a critical feature for continuous processes like oil refining, where unplanned downtime can cost thousands per minute.

Typical application scenarios

In a combined cycle power plant, UAD154A 3BHE026866R0101 monitors key parameters of the gas turbine: exhaust temperature (via K-type thermocouples), combustion pressure (4-20 mA transmitters), bearing vibration (4-20 mA accelerometers), and fuel flow (0-10 V meters). The module’s high isolation protects against noise from the turbine’s high-voltage systems, while its accuracy ensures the control system maintains optimal combustion efficiency. Data from UAD154A 3BHE026866R0101 is processed by the AC800M DCS to adjust fuel valves and air intake, maximizing power output while minimizing emissions.

In a food and beverage pasteurization line, UAD154A 3BHE026866R0101 measures product temperature (Pt100 RTDs), heater pressure (4-20 mA), and conveyor speed (0-10 V). Its ability to handle both RTD and current signals simplifies integration with diverse sensors, while its -40°C to 70°C operating range withstands the temperature swings near pasteurization units. The module’s fast sampling rate (10 Hz) ensures the PLC can quickly adjust heater power if product temperature deviates from the 72°C target, preventing under-pasteurization or overheating.

ABB UAD154A 3BHE026866R0101

Related model recommendations

UAD151A 3BHE026863R0101: A 4-channel variant of UAD154A 3BHE026866R0101 for smaller systems requiring fewer inputs.

UAO144A 3BHE026876R0101: ABB’s analog output module that complements UAD154A 3BHE026866R0101, providing control signals to valves and actuators.

500CPU05 1MRB150081R1/E: ABB’s PLC that processes data from UAD154A 3BHE026866R0101 for automated process control.

PFTL201C 3BSE007913R50 50KN: ABB’s force sensor whose 4-20 mA output integrates seamlessly with UAD154A 3BHE026866R0101.

CTI21-PEX 3BDH000741R1: ABB’s communication module that enables remote monitoring of UAD154A 3BHE026866R0101 data via PROFINET.

TB857: ABB’s surge protection terminal block that safeguards UAD154A 3BHE026866R0101 from voltage transients in industrial environments.

HMI60: ABB’s touchscreen panel that visualizes real-time measurements from UAD154A 3BHE026866R0101, allowing operators to set alarms and view trends.

Installation, commissioning and maintenance instructions

Installation preparation: Insert UAD154A 3BHE026866R0101 into the designated slot of an AC800M or compatible backplane, ensuring proper alignment with the connector. Secure with the front-panel screw (torque to 0.5 Nm). Connect field devices to the terminal block using 0.5-1 mm² shielded cable, grounding shields at the module end. Power the backplane with 24 V DC, ensuring the supply meets ±15% tolerance. Required tools include a screwdriver, wire strippers, and a multimeter for signal verification. Power off the backplane during installation.

Configuration steps: Use ABB’s Automation Builder software to configure each channel’s signal type (e.g., 4-20 mA, Pt100). Set scaling parameters (e.g., 4 mA = 0 kPa, 20 mA = 1000 kPa) and alarm thresholds. Perform a loop test by injecting a known signal (e.g., 12 mA for 50% FS) and verifying the module’s output to the controller. Save configuration to non-volatile memory to preserve settings during power cycles.

Maintenance suggestions: Inspect UAD154A 3BHE026866R0101 quarterly for loose terminal connections and dust accumulation, cleaning with compressed air if necessary. Calibrate annually using a precision signal generator and ABB’s Calibration Toolkit, verifying accuracy across the full range of used signals. Check isolation resistance yearly with a megohmmeter (minimum 100 MΩ at 500 V DC). If channels fail to respond or drift beyond specifications, replace the module—use only ABB-certified units to maintain system compatibility and safety certifications.

Service and guarantee commitment

UAD154A 3BHE026866R0101 comes with a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with published accuracy specifications. ABB guarantees technical support response within 4 hours for critical applications, with on-site service available in 72 hours for qualified process plants. The module includes free access to configuration software and firmware updates for the first 3 years. Extended service contracts offer annual calibration, preventive maintenance, and priority support, ensuring UAD154A 3BHE026866R0101 maintains measurement integrity throughout its 15-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, configuration guides, and troubleshooting manuals specific to this model.