Description

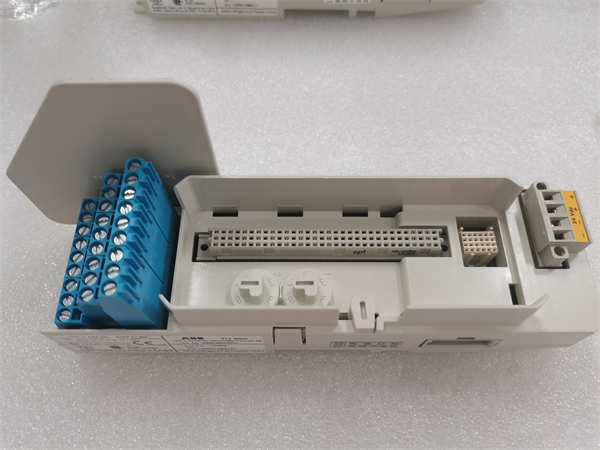

ABB TU890 Module Termination Unit (MTU)

The TU890 is a Module Termination Unit (MTU) developed by ABB, designed to serve as a critical interface between field devices and control systems in industrial automation setups, particularly in hazardous environments. As part of ABB’s S800 I/O system, the TU890 provides secure and reliable signal termination with intrinsic safety features, making it ideal for applications where safety and precision are paramount, such as chemical processing, oil and gas, and power generation.

1. Product Description

The TU890 acts as a physical connection point that bridges the gap between S800 I/O modules (e.g., AI890, DI890) and field devices like sensors and actuators. Its core functions include:

- Intrinsic Safety Isolation: Complies with ATEX/IECEx Zone 2 standards, ensuring safe operation in explosive atmospheres by preventing electrical sparks from reaching hazardous areas.

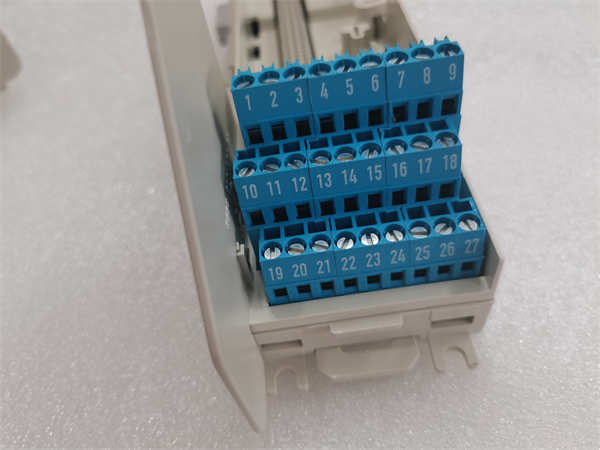

- Signal Termination: Supports up to 27 field devices through 3×9 signal terminals, with color-coded wiring separators for easy installation and maintenance.

- Wide Compatibility: Works seamlessly with ABB’s S800 I/O modules and third-party devices, accepting both analog (4–20mA, 0–10V) and digital (NAMUR sensors, voltage-free contacts) signals.

- Compact and Rugged Design: Engineered to withstand harsh conditions, including temperatures ranging from -40°C to +70°C during storage and 0°C to +55°C during operation, while occupying minimal space in control cabinets.

The TU890 simplifies system integration by providing a standardized termination solution that enhances signal integrity and reduces the risk of electrical faults in critical industrial environments.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | TU890 |

| Type | Module Termination Unit (MTU) |

| Safety Certification | ATEX/IECEx Zone 2 (suitable for Zone 0/1 connections) |

| Signal Terminals | 3×9 isolated terminals (27 total), rated for 50V isolation |

| Wiring Capacity | Supports solid/stranded wires (0.2–4 mm²) |

| Voltage Supply | 24V DC ±10% (derived from S800 I/O system) |

| Operating Temperature | 0°C to +55°C (non-condensing humidity: 5%–95%) |

| Storage Temperature | -40°C to +70°C |

| Dimensions (H×W×D) | 194mm × 58.5mm × 64mm |

| Weight | 0.3 kg |

| Compatibility | ABB S800 I/O modules (AI890, DI890, AO890) and third-party devices |

| Certifications | CE, RoHS, ATEX/IECEx, marine compliance (ABS, BV, DNV-GL) |

ABB TU890

3. Advantages and Features

- Enhanced Safety Compliance: The TU890 meets strict intrinsic safety standards (IEC 60079-11), reducing the risk of ignition in explosive environments. This feature is critical for industries like oil and gas, where even minor electrical faults can lead to catastrophic failures.

- Flexible Signal Handling: Supports a wide range of signal types, eliminating the need for multiple termination units. For example, it can simultaneously connect pressure sensors (4–20mA) and safety switches (digital signals), simplifying wiring and configuration.

- Space-Efficient Design: At 194mm × 58.5mm × 64mm, the TU890 is 30% more compact than traditional terminal blocks, making it ideal for retrofitting into existing control cabinets with limited space.

- Reliable Performance: Built with industrial-grade materials, the module resists electromagnetic interference (EMI) and vibrations, ensuring stable signal transmission. Its mean time between failures (MTBF) exceeds 100,000 hours, minimizing downtime in mission-critical operations.

- Cost-Effective Integration: By integrating intrinsic safety barriers directly into the termination unit, the TU890 reduces hardware costs by up to 20% compared to using separate safety modules and terminal blocks.

4. Application Areas and Case Study

Application Areas:

- Chemical Processing: Monitors and controls reactant flow, pressure, and temperature in chemical reactors and distillation units.

- Oil and Gas: Manages valves, pumps, and gas sensors in offshore platforms, refineries, and pipelines.

- Power Generation: Integrates with turbines and generators to ensure safe voltage and current regulation.

- Pharmaceuticals: Controls sterile processes in cleanrooms, where strict safety and precision are non-negotiable.

Case Study:

A major chemical plant in the Middle East deployed the TU890 to connect its S800 I/O system with field devices in a hazardous production area. The module’s intrinsic safety features and EMI resistance reduced false alarms from temperature sensors by 35%, improving operational safety and reducing unnecessary shutdowns. Additionally, its compact design allowed the plant to fit more termination units in existing cabinets, accelerating system expansion by 20%.

5. Competitive Comparison

Compared to similar termination units in the market, the TU890 stands out for:

- Comprehensive Safety Certifications: Offers ATEX/IECEx Zone 2 compliance, a feature not universally available in competing products, especially those designed for non-hazardous areas.

- Dual Signal Compatibility: Natively supports both analog and digital signals in a single unit, whereas many alternatives require separate modules for different signal types.

- Marine and Industrial Compliance: Meets marine certification standards (ABS, BV, DNV-GL), making it suitable for offshore and harsh marine environments, a niche where few competitors offer equivalent solutions.

ABB TU890

6. Selection Recommendations

- Safety Requirements: Prioritize the TU890 if your application operates in or near hazardous areas (Zone 2) and requires intrinsic safety isolation.

- Signal Type Mix: If your system uses a combination of analog and digital field devices, the TU890’s dual signal support will streamline wiring and reduce component count.

- Environmental Conditions: For installations with temperature fluctuations or high humidity, verify that the module’s operating range (0°C to +55°C) and non-condensing humidity tolerance (5%–95%) match your site’s conditions.

- System Scalability: Pair the TU890 with ABB’s S800 I/O modules (e.g., AI890 for analog input, DI890 for digital input) to create a fully integrated automation solution that supports future expansions.

7. Precautions

- Installation:

- Always power down the entire system before connecting or disconnecting the TU890 to prevent electrostatic discharge (ESD) damage to sensitive components.

- Use shielded cables for signal connections and route them separately from high-voltage power cables to minimize EMI interference.

- Maintenance:

- Regularly inspect terminal connections for tightness and corrosion, especially in humid or corrosive environments.

- Update firmware using ABB’s official software (e.g., Control Builder M) to ensure compatibility with the latest system updates and security patches.

- Storage:

- Store unused TU890 modules in their original packaging in a dry, dust-free environment within the specified storage temperature range (-40°C to +70°C).

- Handle the module with anti-static wrist straps to protect against ESD during handling and installation.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.