Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

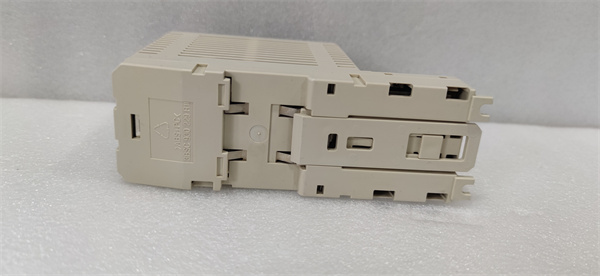

| Product Model | ABB TB820V2 3BSE013208R1 |

| Manufacturer | ABB |

| Product Category | High-density Termination Board |

| Compatible System | S800 I/O, AC 800M Controller |

| Connection Type | Spring-clamp terminal block |

| Number of Channels | 32 (16 pairs) |

| Wire Size | 0.2-1.5mm² (AWG 24-16) |

| Terminal Type | Removable, pluggable |

| Isolation Voltage | 500V AC |

| Operating Temperature | -25°C to +70°C |

| Mounting | Directly to S800 I/O module |

| Material | Flame-retardant PC/ABS blend |

| Dimensions | 60mm × 125mm × 35mm |

| Weight | 180g |

| Protection Class | IP20 (when mounted) |

TB820V2 3BSE013208R1

Product Introduction

The ABB TB820V2 3BSE013208R1 represents the next generation of high-density termination boards for ABB’s S800 I/O system, designed to maximize space efficiency in control cabinets while maintaining superior connection reliability. This advanced termination solution doubles the channel density compared to standard termination boards, making it ideal for applications where panel space is at a premium.

Engineered for use with ABB’s AC 800M controllers, the TB820V2 features innovative spring-clamp technology that reduces installation time while ensuring vibration-resistant connections. The board’s optimized layout minimizes cross-talk between channels, preserving signal integrity in electrically noisy industrial environments.

Particularly suited for large-scale automation projects in process industries, the ABB TB820V2 3BSE013208R1 offers maintenance engineers the convenience of tool-less wiring and the reliability expected from ABB’s industrial components.

Core Advantages and Technical Highlights

Space-Saving High-Density Design:

With 32 connection points in the same footprint as standard 16-channel boards, the TB820V2 enables 50% more I/O in the same cabinet space, reducing installation costs.

Tool-Less Spring-Clamp Technology:

The innovative terminal design allows fast, secure connections without special tools, significantly reducing wiring time compared to screw terminals.

Enhanced Signal Integrity:

Precision-molded separation barriers and optimized conductor routing minimize electromagnetic interference between channels, critical for analog signal applications.

Maintenance-Friendly Architecture:

The pluggable design permits module replacement without disturbing field wiring, while clear channel numbering simplifies troubleshooting.

Robust Construction:

Flame-retardant material (UL94 V-0 rated) withstands industrial environments, with wide temperature tolerance (-25°C to +70°C) for reliable operation.

Universal Compatibility:

Maintains full mechanical and electrical compatibility with existing S800 I/O modules, protecting investments in ABB control systems.

TB820V2 3BSE013208R1

Typical Application Scenarios

The ABB TB820V2 3BSE013208R1 excels in:

Large Process Plants:

Petrochemical refinery DCS systems

Pharmaceutical batch process control

Food & beverage production lines

Energy Infrastructure:

Power plant distributed control systems

Renewable energy farm monitoring

District heating network automation

Water Management:

SCADA systems for water treatment

Pump station control panels

Flood prevention monitoring networks

Transportation Hubs:

Airport baggage handling systems

Metro signaling control cabinets

Port cargo handling automation

Related Model Recommendations

ABB TB821V2 (3BSE013209R1): Surge-protected version

ABB TB830V2 (3BSE013210R1): Intrinsically safe variant

ABB TB840V2 (3BSE013211R1): High-current version (5A per channel)

ABB CI840V2 (3BSE013212R1): Communication interface module

ABB AI840V2 (3BSE013213R1): High-density analog input

ABB DI840V2 (3BSE013214R1): 32-channel digital input

ABB DO840V2 (3BSE013215R1): 32-channel digital output

ABB S800C (3BSE013216R1): Compact I/O extension module

Installation and Maintenance Guidelines

Installation Preparation:

Verify compatibility with specific S800 I/O module. Prepare wires with proper stripping length (7-8mm). Ensure work area is clean and free of metallic debris.

Commissioning Procedure:

Align board with module guides and press firmly until click is heard

Insert wires straight into terminal openings until they bottom out

Verify all connections with gentle pull test

Perform continuity checks before power-up

Maintenance Best Practices:

Annual inspection of terminal tension

Periodic cleaning with non-static brush

Immediate replacement of any damaged terminals

Regular backup of configuration settings

Service and Warranty Information

ABB provides a comprehensive 36-month warranty for the TB820V2 3BSE013208R1, covering:

Defects in materials and workmanship

Performance below specified parameters

Premature wear under normal operating conditions

Extended service offerings include:

Priority replacement program (next-business-day delivery)

On-site technical support

Custom labeling services for large projects

Training programs for proper installation techniques

All termination boards undergo 100% functional testing before shipment, including:

Insertion force verification

Insulation resistance testing

Mechanical durability cycling

Environmental stress screening