Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | SUE3000 1VCR007346 G0028 |

| Manufacturer | ABB |

| Product category | Safety controller module |

| Safety integrity level | SIL 3 (per IEC 61508) |

| Number of safety inputs | 16 (24 V DC, PNP/NPN configurable) |

| Number of safety outputs | 8 (relay, 2 A per channel) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | ≤15 W |

| Processor | Dual-core safety MCU (16-bit) |

| Memory | 256 KB EEPROM (program storage) |

| Communication interface | Safety over EtherCAT (FSoE), RS485 |

| Response time | ≤10 ms (max) |

| Operating temperature | -20 °C to +60 °C |

| Protection rating | IP20 (when mounted in enclosure) |

| Dimensions (W × H × D) | 120 mm × 160 mm × 80 mm |

| Mounting type | DIN rail mount (35 mm) |

| Certifications | IEC 61508, ISO 13849-1 (PL e), CE, UL |

| Weight | 0.5 kg |

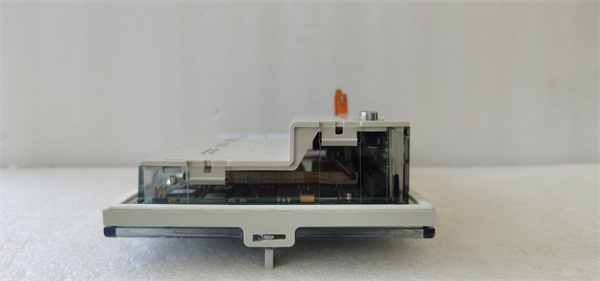

ABB SUE3000 1VCR007346 G0028

Product introduction

The SUE3000 1VCR007346 G0028 is a high-integrity safety controller module from ABB, designed to monitor and control safety-critical functions in industrial automation systems. As part of ABB’s SafeEco line, this module provides a robust layer of protection, ensuring that hazardous conditions—such as machinery overspeed, unauthorized access, or equipment malfunctions—trigger immediate safety responses, such as emergency stops or process shutdowns.

What distinguishes the SUE3000 1VCR007346 G0028 is its compliance with SIL 3 (Safety Integrity Level) and PL e (Performance Level e), making it suitable for applications where human safety and equipment protection are paramount. Its dual-core processor architecture ensures redundant processing of safety logic, minimizing the risk of systematic failures. Whether integrated into manufacturing cells, conveyor systems, or process lines, the SUE3000 1VCR007346 G0028 acts as a failsafe, bridging safety sensors (e.g., light curtains, emergency stop buttons) and actuators (e.g., contactors, valves) to prevent accidents.

Core advantages and technical highlights

Dual-core safety architecture: The SUE3000 1VCR007346 G0028 features two independent 16-bit safety MCUs that continuously cross-verify each other’s operations. This redundancy eliminates single points of failure—if one core detects a discrepancy in logic execution, the module enters a safe state, ensuring no unsafe outputs are generated. In automotive welding cells, this redundancy is critical, as a single failure could lead to robotic arm collisions with operators.

Flexible safety I/O: With 16 configurable safety inputs (compatible with both PNP and NPN sensors) and 8 relay outputs, the module adapts to diverse safety devices. For example, inputs can connect to light curtains (Type 4), emergency stop buttons (EN ISO 13850), and interlock switches, while outputs control safety contactors or valve shutoffs. This flexibility reduces the need for additional interface modules, simplifying system design.

Fast response and communication: A maximum response time of 10 ms ensures rapid reaction to safety events. In a packaging machine, for instance, the SUE3000 1VCR007346 G0028 can detect a hand intrusion via a light curtain and stop the machine within 10 ms, preventing crush injuries. Its Safety over EtherCAT (FSoE) interface enables real-time communication with other safety devices and the main control system, allowing for centralized monitoring of safety status.

SIL 3/PL e compliance: Rigorous certification to IEC 61508 (SIL 3) and ISO 13849-1 (PL e) validates the module’s ability to operate in high-risk environments. This compliance is essential for industries like oil and gas, where a safety failure could result in explosions or environmental damage, or in pharmaceutical manufacturing, where equipment overspeed might contaminate sterile processes.

Typical application scenarios

In automotive assembly plants, the SUE3000 1VCR007346 G0028 safeguards robotic workcells. It connects to 8 emergency stop buttons (inputs) and 4 light curtains (Type 4) surrounding the cell, while outputs control 4 safety contactors that cut power to robotic arms. If an operator breaches the light curtain or presses an emergency stop, the module triggers a shutdown within 8 ms, preventing collisions. FSoE communication sends safety status to the plant’s SCADA system, logging the event for audit purposes.

Within material handling systems—such as overhead conveyors in warehouses—the SUE3000 1VCR007346 G0028 monitors 12 interlock switches on conveyor access doors and 4 speed sensors. If a door is opened (interlock triggered) or the conveyor exceeds safe speed, the module activates 6 relay outputs to stop the motor and engage brakes. Its wide operating temperature range (-20 °C to +60 °C) ensures reliability in unheated warehouse environments.

In chemical processing facilities, the module controls safety shutdowns for reactor systems. It receives inputs from 10 pressure/temperature sensors (with safety integrity) and 6 gas leak detectors, using 8 outputs to close isolation valves and shut down pumps if thresholds are exceeded. SIL 3 compliance ensures these actions are performed with a probability of failure on demand (PFD) below 10⁻³, meeting regulatory requirements for hazardous chemical handling.

ABB SUE3000 1VCR007346 G0028

Related model recommendations

ABB SUE2000 1VCR007345 G0027: A compact SIL 2 safety controller with 8 inputs/4 outputs, ideal for smaller systems where the SUE3000 1VCR007346 G0028’s capacity is unnecessary.

ABB PP886 3BSE092980R1: An operator panel that displays safety status from the SUE3000 1VCR007346 G0028, allowing operators to acknowledge alarms and reset safety systems.

ABB AC800M 3BSE018105R1: A process controller that integrates with the SUE3000 1VCR007346 G0028 via FSoE, enabling coordinated shutdowns of non-safety and safety functions.

ABB TB840A 3BSE037760R1: A module bus modem that extends FSoE communication between the SUE3000 1VCR007346 G0028 and remote safety devices in large facilities.

ABB MS132-10: A safety contactor rated for 10 A, paired with the SUE3000 1VCR007346 G0028’s outputs to control higher-power machinery.

ABB light curtain 440L-2R1200: A Type 4 safety sensor connected to the module’s inputs, providing perimeter protection for hazardous machinery.

Installation, commissioning and maintenance instructions

Installation preparation: Mount the SUE3000 1VCR007346 G0028 on a 35 mm DIN rail in a dust-tight enclosure (IP54 or higher) to maintain IP20 protection. Ensure the ambient temperature remains within -20 °C to +60 °C and avoid proximity to high-voltage cables to reduce EMI. Connect 24 V DC power via a dedicated safety power supply (with isolation), fused at 1 A. Use twisted-pair shielded cables for inputs/outputs and communication, grounding shields at both ends. Verify that all safety devices (e.g., E-stops, light curtains) meet compatible safety ratings before wiring.

Maintenance suggestions: Inspect the SUE3000 1VCR007346 G0028 quarterly for loose connections or corrosion, especially in humid environments. Test safety functions monthly by simulating faults (e.g., triggering an E-stop) and verifying output activation. Use ABB’s Safety Builder software to check diagnostic logs for anomalies, such as input signal fluctuations. Calibrate response times annually using a signal generator to ensure compliance with SIL 3 requirements. Replace the module if it fails certification tests, using only ABB-approved replacements to maintain safety integrity.

Service and guarantee commitment

The SUE3000 1VCR007346 G0028 comes with a 3-year warranty, covering manufacturing defects and ensuring compliance with SIL 3/PL e standards. ABB’s safety-certified technical team provides 24/7 support for installation, logic programming, and troubleshooting, including assistance with safety lifecycle documentation (e.g., risk assessments, validation reports).

Extended services include on-site safety audits, firmware updates, and recertification support to maintain compliance with evolving standards. ABB guarantees that the SUE3000 1VCR007346 G0028 will interoperate with other ABB safety devices and provide the specified safety integrity throughout its lifecycle, reinforcing its commitment to protecting workers and critical infrastructure.