Description

Detailed parameter table

| Parameter name | Parameter value |

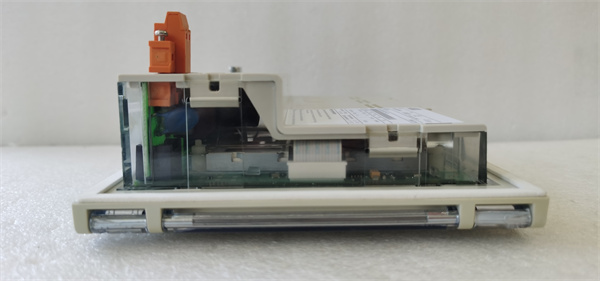

| Product model | SUE3000 1VCR007346 G0028 |

| Manufacturer | ABB |

| Product category | High – speed motor bus transfer solution |

| Dimensions (approx.) (WxHxD in mm) | 263×58×28 |

| Weight | 4.3 kg |

| Country of origin | United States of America |

| Input voltage range | 0 – 55 VDC |

| Frequency range | 14 to 60kHz |

| Transfer modes | Four different configurable motor bus transfer modes |

| Circuit – breaker configuration | Configurable with two or three circuit – breakers |

| Communication protocols | Flexible bus protocol communication concept including IEC 61850 – 8 – 1 MMS, IEC 60870 – 5 – 103, Ethernet interface, Modbus TCP, Modbus RTU, Profibus DP and ABB SPA; also supports IEC 61850 ed.1 and 2 with GOOSE, SV and MMS, DNP 3 TCP, IEC 103 – 104, SNTP, PTP v2, PRP and HSR |

| Supervision and monitoring | Permanent supervision of involved incomers, busbars and circuit breakers; integrated disturbance recorder and watchdog self – monitoring |

| Safety features | Integrated safety features such as coil supervision function and decoupling function |

| Transfer time | Typical transfer time is about 100 ms, can be reduced to around 30 ms when used with Rex 542 plus relays and vacuum circuit breaker VM 1 – T, depending on circuit breaker time, fault detection time, and the state of the incoming lines involved |

ABB SUE3000 1VCR007346 G0028

Product introduction

The ABB SUE3000 1VCR007346 G0028 is a high – speed motor bus transfer solution that plays a crucial role in maintaining continuous power supply in industrial and commercial settings. Engineered by ABB, a globally renowned leader in electrical and automation technologies, this product is designed to meet the high – demand requirements of modern power distribution systems.

The SUE3000 functions as a safeguard for critical processes by ensuring a seamless transfer from the main power source to a standby power source. In scenarios where the main incomer experiences an outage, fault, or voltage instability, the SUE3000 steps in. It automatically and rapidly switches the power supply to the standby incomer, minimizing power interruption times. This is of utmost importance in industries where even a brief power cut can lead to significant losses, such as in manufacturing plants where production lines may come to a halt, or in data centers where server operations need to be uninterrupted.

Core advantages and technical highlights

Rapid transfer speed: One of the most significant features of the SUE3000 is its ability to execute high – speed transfers. With a typical transfer time of around 100 ms, and the potential to reduce it to approximately 30 ms when paired with specific components like Rex 542 plus relays and vacuum circuit breaker VM 1 – T, it can quickly re – route power. This rapid transfer ensures that downstream processes experience minimal disruption, protecting against costly outages. For example, in a chemical plant where continuous reactions are taking place, a quick power transfer can prevent product spoilage and equipment damage due to sudden stoppages.

Flexible configuration: It offers great flexibility in terms of circuit – breaker configuration, allowing for setups with two or three circuit – breakers. Additionally, there are four different configurable motor bus transfer modes. This adaptability makes it suitable for a wide range of power distribution systems, whether in small – scale commercial buildings or large – scale industrial complexes. Users can choose the configuration and transfer mode that best suits their specific power requirements and system layout.

Comprehensive supervision and monitoring: The SUE3000 comes equipped with a permanent supervision system that keeps a close eye on involved incomers, busbars, and circuit breakers. An integrated disturbance recorder captures any anomalies in the power supply, which can be invaluable for troubleshooting and preventive maintenance. The watchdog self – monitoring feature ensures that the device itself is operating correctly at all times, enhancing overall system reliability.

Enhanced safety features: Safety is a top priority, and the SUE3000 addresses this with its integrated safety features. The coil supervision function monitors the health of coils in the circuit, and the decoupling function helps in isolating faulty components. These safety mechanisms not only protect the device but also the connected electrical equipment and personnel, reducing the risk of electrical accidents and equipment failures.

Versatile communication capabilities: With a wide range of supported communication protocols, the SUE3000 can integrate seamlessly with various control systems. Whether it’s an IEC 61850 – based smart grid system or an older Modbus – RTU – based control network, the device can communicate effectively. This enables easy integration into existing power management systems and allows for remote monitoring and control, providing operators with real – time information about the power transfer status.

Typical application scenarios

Industrial manufacturing: In factories, especially those with continuous production processes such as automotive assembly lines, textile mills, or food and beverage production plants, the SUE3000 is essential. A power interruption in these settings can lead to production halts, damaged products, and significant financial losses. The SUE3000 ensures that the production lines keep running by quickly switching to the standby power source, maintaining the operation of machinery like conveyor belts, robotic arms, and processing equipment.

Data centers: Data centers house critical IT infrastructure that requires uninterrupted power. Even a momentary power loss can cause servers to crash, leading to data loss, service disruptions, and potential damage to expensive equipment. The SUE3000’s fast transfer speed and reliable performance make it an ideal choice for data centers. It can work in tandem with backup generators or uninterruptible power supply (UPS) systems to ensure that the servers and associated cooling and networking equipment receive continuous power.

Hospitals: In healthcare facilities, life – support systems, operating room equipment, and patient monitoring devices rely on a stable power supply. The SUE3000 can safeguard these essential services. In the event of a power grid failure, it can rapidly transfer power to the standby generator, ensuring that medical procedures can continue without interruption and that patient safety is not compromised.

Commercial buildings: Large shopping malls, hotels, and office buildings often have multiple electrical systems, including lighting, HVAC (heating, ventilation, and air – conditioning), and elevators. The SUE3000 can be used to ensure that these systems continue to operate during power outages. For example, in a shopping mall, continuous power supply to escalators and lighting is crucial for customer safety and convenience.

ABB SUE3000 1VCR007346 G0028

Comparison with related models in the series

Compared with ABB SUE4000: While both the SUE3000 and SUE4000 are high – speed bus transfer solutions, the SUE4000 may be more suitable for larger – scale, more complex power distribution systems. It might offer additional features or higher – capacity handling capabilities. However, the SUE3000 provides a more cost – effective and compact solution for applications where the scale is smaller or the budget is more constrained. For instance, a small – to – medium – sized manufacturing plant may find the SUE3000 sufficient for its power transfer needs, while a large industrial complex with multiple high – power production lines may opt for the SUE4000.

Compared with other brands’ similar products: ABB’s SUE3000 stands out due to ABB’s long – standing reputation for quality and reliability. ABB has a vast global network of research and development, manufacturing, and technical support facilities. This means that customers can expect better – engineered products, longer – lasting performance, and more comprehensive technical support. Competing products may not offer the same level of integration with ABB’s extensive range of electrical and automation products. ABB also invests heavily in research and development to continuously improve its products, ensuring that the SUE3000 incorporates the latest technological advancements in power transfer, giving it an edge over similar products from other brands.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the SUE3000 1VCR007346 G0028, carefully assess the installation site. Ensure that the area is clean, dry, and free from excessive dust and moisture. Check the electrical supply to confirm that it falls within the specified input voltage range. Gather all the necessary installation tools, such as screwdrivers, wire strippers, and crimping tools. If the device is to be integrated into an existing power distribution system, review the compatibility of the communication interfaces and the overall system architecture. Also, make sure that the power system in the installation area has been properly shut down and isolated to prevent any electrical accidents during installation.

Commissioning process: Once installed, connect the SUE3000 to the relevant power sources, circuit breakers, and control systems according to the provided wiring diagrams. Double – check all connections to ensure they are secure and properly insulated. Power on the device and perform an initial self – test. Use the device’s built – in configuration tools or connected communication interfaces to set up the transfer modes and other control parameters according to the specific requirements of the application. Test the device’s functionality by simulating a power outage scenario (under controlled conditions) to ensure that the transfer to the standby power source occurs smoothly. Monitor the performance using appropriate testing equipment to ensure that the transfer time, voltage levels, and other parameters are operating as expected. Also, verify the proper functioning of the safety protection features by simulating abnormal conditions to ensure that the coil supervision and decoupling functions work correctly.

Maintenance suggestions: Regularly inspect the SUE3000 for any signs of physical damage, such as cracks in the housing or loose connections. Clean the device periodically using a dry, lint – free cloth to remove any dust that may have accumulated, as dust can affect the performance of the internal components. Check the communication status with other devices in the network at regular intervals to ensure seamless data transfer for monitoring and control purposes. Review the data logs (if available) to look for any patterns or signs of abnormal behavior in the device’s operation. If any issues are detected, refer to the troubleshooting section of the product manual. In case of more complex problems, contact ABB’s technical support team, who can provide remote or on – site assistance. Replace any worn – out or faulty components with genuine ABB parts to maintain the device’s performance and reliability.

Service and guarantee commitment

ABB offers a standard [warranty period] warranty for the SUE3000 1VCR007346 G0028, covering any manufacturing defects. ABB’s global technical support team is available 24/7 to assist customers. They can provide remote support through online communication channels, guiding customers through installation, commissioning, and troubleshooting processes. In cases where on – site assistance is required, trained technicians can be dispatched to the customer’s location. ABB also regularly updates the product’s software and technical documentation to improve performance, add new features, and address any potential security vulnerabilities. This commitment to service and support ensures that customers can rely on the SUE3000 for long – term, reliable operation in their power distribution systems.