Description

Key Technical Specifications

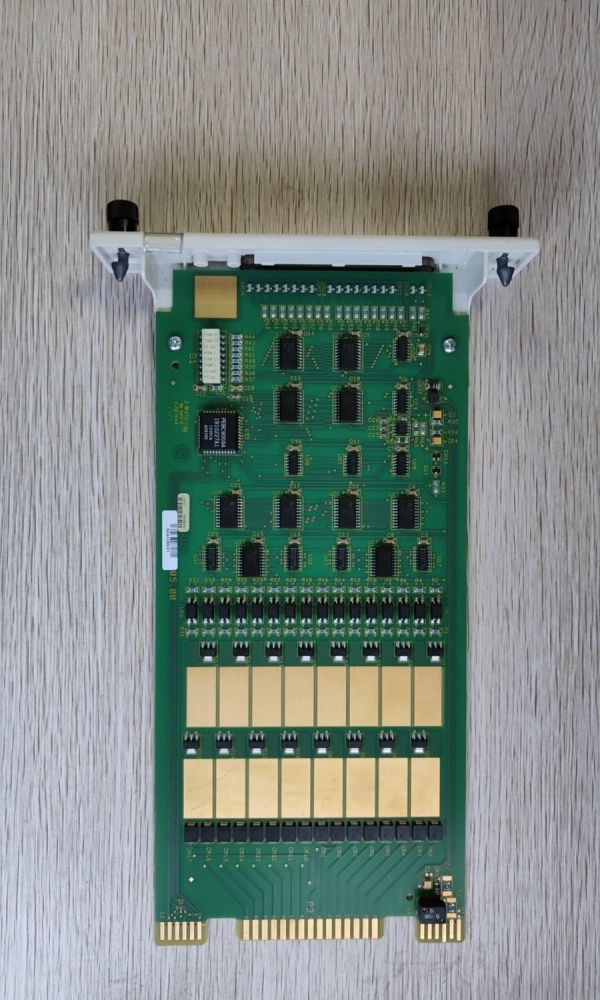

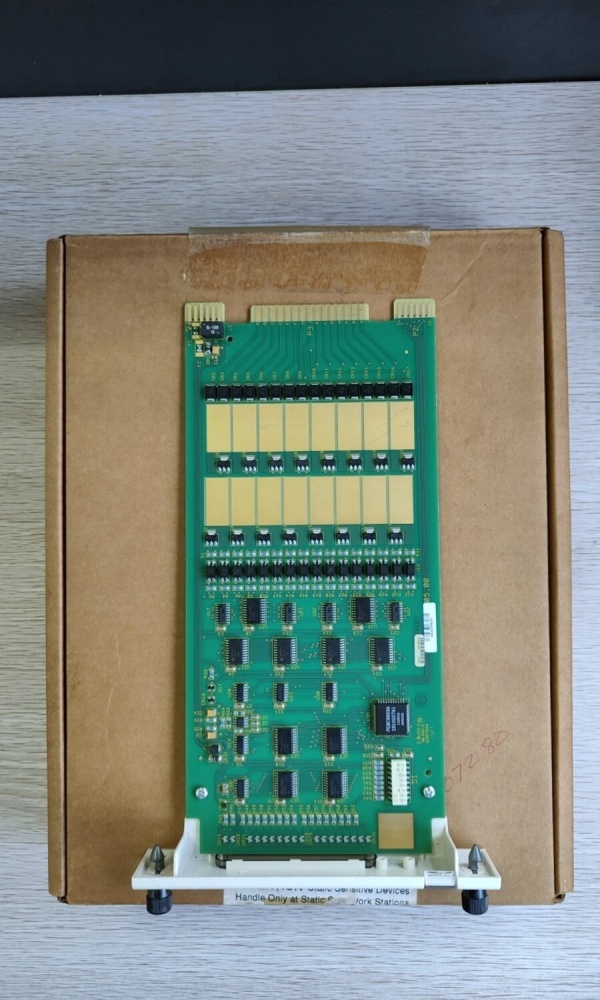

- Model Number: SPDS014

- Manufacturer: ABB Process Automation

- Input Voltage: 24VDC ±10% (dual redundant input ports: IN1, IN2)

- Output Voltage: 24VDC ±5% (regulated for I/O module compatibility)

- Output Current Capacity: 10A total (supports up to 12 S800 I/O modules per rack)

- Protection Features: Overcurrent protection (auto-reset), reverse polarity protection, short-circuit protection

- Redundancy Support: 1:1 hot standby (automatic switchover < 5ms if primary input fails)

- Backplane Compatibility: ABB S800 I/O rack backplane (mandatory slot 1 installation)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Protection Rating: IP20 (rack-mounted, indoor control cabinet use)

- Certifications: UL 508, CE, ATEX Zone 2, IEC 61010

- Mounting: Rack-mounted (occupies slot 1 of S800 I/O rack; non-negotiable)

ABB SPDS014

Field Application & Problem Solved

In process plants running AC 800M DCS with S800 I/O racks, the single biggest risk to I/O system uptime is power supply failure. Legacy non-redundant power supplies create a single point of failure—one blown fuse or voltage dip takes an entire I/O rack offline, leading to process upsets and unplanned downtime. A Gulf Coast refinery once lost 6 hours of production when a non-redundant power supply failed on a rack controlling reactor feed valves, costing $250k in lost revenue.

The SPDS014 solves this by providing redundant power distribution to S800 I/O racks. You’ll find this module in every critical S800 I/O installation—typically in refinery crude distillation units, chemical plant reactor sections, and power plant turbine control systems. It accepts two independent 24VDC power feeds (primary from the main control system, secondary from a UPS) and distributes regulated power to all I/O modules in the rack. If the primary power feed fails, the module switches to the secondary feed in < 5ms—fast enough that the I/O modules never detect a disruption.

Its core value is high availability paired with load regulation. Unlike generic power splitters, the SPDS014 regulates output voltage to ±5% of 24VDC, protecting sensitive I/O electronics from voltage spikes or dips common in plant power grids. I’ve used this module in a Texas petrochemical plant where grid voltage fluctuates by ±15% during peak demand—the SPDS014 kept the I/O rack online through every fluctuation, while generic splitters caused frequent I/O communication faults.

Installation & Maintenance Pitfalls (Expert Tips)

Slot 1 Installation Is Mandatory: Rookies try to install the SPDS014 in non-slot-1 positions to free up space for I/O modules, resulting in “rack not recognized” faults. The S800 I/O rack backplane is hard-wired to deliver power only through slot 1—no exceptions. Always verify slot position before powering on the rack; this 10-second check prevents hours of troubleshooting. I fixed a power plant’s I/O rack outage by moving the SPDS014 from slot 3 to slot 1—simple, but costly if missed.

Dual Inputs Must Come From Separate Power Sources: The module has two input ports, but rookies connect both to the same 24VDC supply. If that supply fails, the rack goes down—defeating the purpose of redundancy. Connect IN1 to the plant’s main control system power and IN2 to a dedicated UPS or backup generator. At a Florida combined-cycle power plant, this setup kept the I/O rack online during a 2-hour grid outage, preventing a turbine trip.

Overcurrent Protection Is Not a Substitute for Proper Load Sizing: The SPDS014 has auto-reset overcurrent protection, but rookies overload the module by connecting 15+ I/O modules to a single rack (exceeding the 10A output limit). Overloading causes the module to cycle into overcurrent protection, leading to intermittent power loss to I/O modules. Calculate total load before configuring the rack—each S800 I/O module draws 0.2–0.8A; never exceed 10A total. A Louisiana chemical plant fixed intermittent I/O faults by splitting a 14-module rack into two 7-module racks, each with its own SPDS014.

LED Status Diagnostics Are Your First Line of Defense: The module’s front-panel LEDs (PWR1, PWR2, OK, FAULT) provide real-time power status feedback—rookies ignore them until a fault occurs. PWR1 = primary input active, PWR2 = secondary input active, OK = normal operation, FAULT = overcurrent or voltage fault. During routine inspections, verify both PWR1 and PWR2 LEDs are lit—if one is off, investigate the power source before it fails. This proactive check prevented a refinery’s I/O rack outage by identifying a failing UPS before it went down.

ABB SPDS014

Technical Deep Dive & Overview

The SPDS014 is a microprocessor-controlled power distribution module designed exclusively for ABB S800 I/O racks. At its core, it uses two independent power rectifier circuits to accept dual 24VDC inputs, with a redundant switchover circuit that monitors input voltage continuously. If the primary input voltage drops below 20.4VDC (the low end of the ±10% tolerance range), the switchover circuit activates the secondary input in < 5ms—fast enough to maintain power to I/O modules without disruption.

The module’s output regulation circuit ensures the voltage supplied to the I/O backplane stays within ±5% of 24VDC, even if input voltage fluctuates by ±10%. This regulation protects sensitive I/O electronics from voltage spikes that can damage optocouplers or microcontrollers in DI/DO/AI/AO modules. Overcurrent protection is provided by a hardware-based current limiter that trips at 11A, then auto-resets after 1 second—eliminating the need for manual fuse replacement.

Unlike generic power splitters, the SPDS014 communicates with the AC 800M DCS via the S800 backplane, transmitting power status and fault data to the DCS HMI. This lets technicians monitor power supply health remotely, without needing to open the control cabinet. The module’s hot-swappable design allows replacement without powering down the I/O rack—critical for 24/7 process plants where downtime is not an option. Built with industrial-grade components and conformal coating to resist dust and moisture, the SPDS014 is a workhorse for critical process control applications, delivering 99.99% uptime when installed correctly.