Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | ABB SPBRC410 |

| Manufacturer | ABB |

| Product Category | Burner Control Module (S800 I/O Series) |

| Safety Certification | SIL 3 (IEC 61508), FM Approved |

| Control Functions | Flame Detection, Purge Control, Fuel Valve Sequencing, Pilot Management |

| Flame Detection Inputs | 2x UV/IR/Ionization Scanners (Configurable) |

| Digital Inputs | 8x 24VDC (Status/Maintenance Signals) |

| Digital Outputs | 6x Relay (5A @ 230VAC) + 2x Solid-State (2A) |

| Response Time | <500 ms (Flame Failure to Shutdown) |

| Communication Interface | S800 I/O Bus + HART Pass-Through |

| Operating Voltage | 24 VDC ±10% (via backplane) |

| Operating Temperature | -40°C to +70°C |

| Enclosure Compatibility | ABB TB811 Termination Board (Required) |

| Certifications | ATEX, IECEx, UL Class I Div 2 |

| Diagnostics | Burner Sequence Logging, Scanner Health Monitoring |

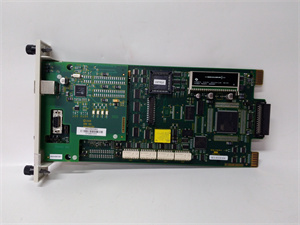

ABB SPBRC410

Product Introduction

The ABB SPBRC410 is a safety-certified burner control module engineered for critical combustion management in industrial heating systems. As part of ABB’s S800 I/O family, this specialized module integrates flame supervision, fuel valve sequencing, and purge cycle control into a single DIN-rail mounted unit. Designed for SIL 3 compliance per IEC 61508, the ABB SPBRC410 prevents furnace explosions by executing failsafe shutdown logic within 500ms of flame failure detection.

Operating within ABB’s System 800xA or Symphony Plus DCS, the module interfaces with UV/IR flame scanners while managing fuel trains and igniters through configurable safety timers. Its dual-redundant processor architecture executes 2-out-of-3 (2oo3) voting for critical decisions, making the ABB SPBRC410 indispensable for boilers, process heaters, and thermal oxidizers where combustion risks demand maximum reliability.

Core Advantages and Technical Highlights

Ultra-Fast Safety Response:

Independent watchdog circuits enforce <500ms shutdown on flame failure

Redundant processors with cross-comparison diagnostics

Solid-state outputs for valve de-energization without contact bounce

Advanced Flame Discrimination:

Adaptive sensitivity tuning for stable detection in dirty optics

Dynamic noise rejection during burner light-off

HART-enabled scanner diagnostics (compatible with ABB UVISOR F series)

Flexible Burner Management:

12-step configurable sequence (purge/ignition/main flame)

Pilot proving time: 1-15 sec (adjustable in 0.1s increments)

Post-purge timing with air flow verification

Robust Hazardous Area Design:

ATEX II 3G Ex ec IIC T4 Gc certification

4kV surge protection on all field connections

Conformal-coated PCB for corrosive flue gas environments

Maintenance Optimization:

Event recorder stores last 50 shutdown causes with timestamps

Simulated flame input for offline testing

Hot-swappable with redundant controllers

Typical Application Scenarios

Refinery Process Heaters: Manages 20+ burner cells in crude heaters, using ABB SPBRC410‘s SIL 3 logic to prevent furnace implosions during trip events. Flame scanners monitor individual burners with cross-flame discrimination.

Power Plant Boilers: Controls igniter gas trains and main coal burners, executing purge cycles compliant with NFPA 85. Solid-state outputs eliminate contact welding risks in sooty environments.

Chemical Thermal Oxidizers: Sequences natural gas/pilot valves while verifying destruction efficiency through continuous flame presence monitoring. ATEX rating allows installation in Zone 2 areas.

Cement Kiln Burners: Withstands kiln shell vibration (5g) while maintaining flame stability during alternative fuel switching. HART diagnostics predict scanner lens fouling.

Marine Incinerators: DNV-GL certified for vessel installations. Salt spray-resistant construction ensures reliability in marine atmospheres.

ABB SPBRC410

Related Model Recommendations

ABB TB811: Dedicated termination board for SPBRC410

ABB UVISOR F Flame Scanners: UV/IR detectors with HART interface

ABB SAIO22: Digital input module for permissive signals

ABB SPASO23: Analog output for air/fuel ratio control

ABB CMA121: PROFIBUS adapter for burner network integration

ABB SD822: Redundant power supply

ABB ZAU100: Ignition transformer with flame-retardant cabling

ABB PFEA111: Flame rod for pilot verification

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Mount on TB811 termination board with DIN rail clip

Ground shield wires at single point (<0.1Ω)

Flame scanner cables: Separate from AC power (>30cm gap)

Verify scanner compatibility (10-30VDC, 4-20mA)

Commissioning Procedure:

Configure burner sequence steps in Control Builder M

Calibrate flame signal thresholds (typically 5-15 μA)

Test safety interlocks: Simulate low air pressure/fuel valve faults

Validate shutdown timing with stopwatch

Maintenance Protocol:

Weekly: Clean scanner viewports with alcohol wipes

Monthly: Verify output contact resistance (<0.5Ω)

Quarterly: Test simulated flame response

Annually: Full functional test with burner offline

5-Year: Replace relay output modules (preventive)

Service and Guarantee Commitment

ABB provides a 60-month warranty for the ABB SPBRC410, including:

24/7 Safety Support: Dedicated burner specialist hotline

SIL Recertification: Annual functional safety audits

Firmware Updates: Security patches per IEC 62443

Repair Service: 5-day turnaround with calibration report

Training: Combustion safety courses at ABB University

All modules undergo 1,000+ burner sequence tests and explosive atmosphere validation (IEC 60079-0). ABB’s Functional Safety Management System complies with IEC 61508:2010 for design and manufacturing.