Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | SNAT634PAC |

| Manufacturer | ABB |

| Product category | Safety controller module (SIL 3/PLe) |

| Safety integrity level | SIL 3 (per IEC 61508), PLe (per ISO 13849-1) |

| Number of safety channels | 16 (configurable as input/output) |

| Communication interfaces | 2 x Safety over PROFINET, 1 x Ethernet (10/100 Mbps), 1 x RS485 |

| Supported protocols | PROFIsafe, Modbus RTU/TCP, OPC UA |

| Processor | Dual-core 32-bit ARM Cortex-R5, 400 MHz (lockstep architecture) |

| Memory | 2 MB RAM, 8 MB flash (safety-related), 16 MB flash (non-safety) |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 7 W |

| Operating temperature | -20°C to 60°C |

| Protection rating | IP20 |

| Mounting type | Backplane mount (compatible with GRBTU 3BSE013175R1) |

| Dimensions | 140mm × 110mm × 80mm |

| Certifications | TÜV SÜD, CE, UL, ATEX, IEC 61508, ISO 13849-1 |

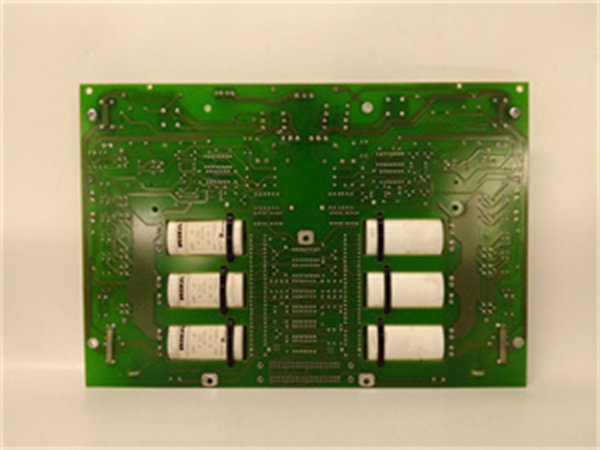

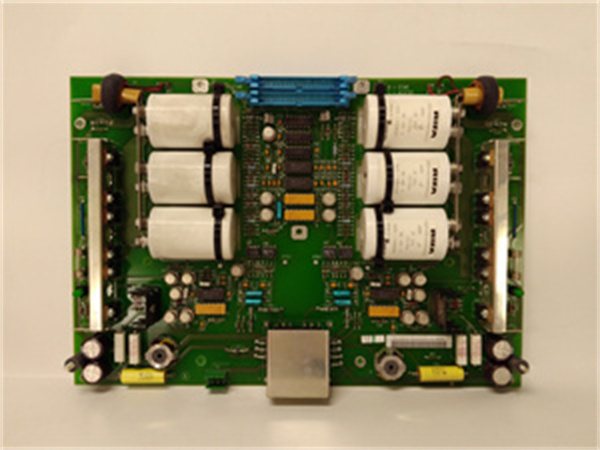

ABB SNAT634PAC

Product introduction

The SNAT634PAC is a high-integrity safety controller module from ABB, engineered to manage safety-critical functions in industrial automation systems. As a core component in ABB’s safety automation portfolio, SNAT634PAC provides fail-safe monitoring and control, ensuring compliance with the most stringent safety standards (SIL 3/PLe) while integrating seamlessly with standard automation components like the CB801 3BSE042245R1 control board and DSDP140B digital input modules.

This module combines dual-core lockstep processing with redundant safety channels, making it ideal for applications where human or equipment safety is paramount—from emergency stop systems in manufacturing lines to shutdown logic in chemical plants. Unlike basic safety relays, SNAT634PAC offers flexible programming and communication via PROFIsafe, enabling it to coordinate with non-safety controllers while maintaining strict separation of safety and standard control functions. Whether deployed in automotive assembly, oil & gas, or pharmaceutical production, SNAT634PAC delivers reliable protection against hazardous events, minimizing risk and ensuring regulatory compliance.

Core advantages and technical highlights

SIL 3/PLe safety certification: SNAT634PAC meets the highest safety integrity levels (SIL 3 per IEC 61508 and PLe per ISO 13849-1), making it suitable for applications where a single fault could lead to severe injury or equipment damage. Its dual-core lockstep processor executes safety logic in parallel, with continuous self-checks to detect hardware anomalies—ensuring a safe state is triggered within 10 ms of a fault detection. In a robotic welding cell, this capability ensures immediate shutdown if a light curtain is breached, preventing contact between operators and moving machinery.

PROFIsafe integration: Equipped with dual PROFIsafe interfaces, SNAT634PAC communicates safety-related data with standard automation systems (such as the 500CPU05 1MRB150081R1/E PLC) without compromising safety integrity. This allows seamless coordination between safety functions (e.g., emergency stops) and standard control (e.g., production sequencing), eliminating the need for separate communication networks. In a food processing line, for example, it can halt a conveyor via safety logic while notifying the main PLC to pause filling operations—maintaining process synchronization during safe shutdowns.

Flexible safety channel configuration: The module’s 16 configurable channels can be set as safety inputs (e.g., for emergency stop buttons, light curtains) or safety outputs (e.g., for shutdown valves, motor contactors) via software. This adaptability allows SNAT634PAC to replace multiple safety relays in complex systems, reducing cabinet space by up to 50%. In a packaging machine, it can monitor 8 emergency stops (inputs) and control 8 safety interlocks (outputs) in a single module, simplifying wiring and diagnostics.

Secure programming and verification: SNAT634PAC uses ABB’s Safety Builder software, which enforces structured programming per IEC 61131-3 with safety-specific libraries (e.g., emergency stop, two-hand control). The software includes built-in verification tools to check for common design errors (e.g., insufficient fault tolerance), ensuring compliance with safety standards. Program changes are logged with user authentication, providing an audit trail required for regulatory inspections in industries like nuclear power or aviation.

Redundant and fault-tolerant design: Beyond its lockstep processor, SNAT634PAC features redundant 24 V DC power inputs and self-monitoring of communication ports, ensuring no single point of failure compromises safety functions. Its wide operating temperature range (-20°C to 60°C) and immunity to electromagnetic interference (EMI) make it reliable in harsh environments, such as steel mills or offshore platforms.

Typical application scenarios

In a chemical plant’s reactor system, SNAT634PAC acts as the safety logic solver for overpressure protection. It monitors pressure transmitters (via safety-rated analog inputs) and temperature sensors (connected through DSDP140B modules with safety relays), executing shutdown logic if process variables exceed critical thresholds. Using PROFIsafe, it communicates with the CB801 3BSE042245R1 control board to isolate the reactor while notifying the main DCS. The module’s SIL 3 certification ensures the shutdown function has a probability of failure on demand (PFD) below 10⁻³, meeting regulatory requirements for hazardous chemical processing.

In an automotive paint shop, SNAT634PAC manages safety interlocks for robotic painting cells. It monitors light curtains, door interlocks, and exhaust system sensors, triggering a safe stop (category 0) if any safety boundary is violated. The controller communicates with the robot PLC via PROFIsafe, ensuring the robots halt within 500 ms of an alarm while maintaining diagnostic data for troubleshooting. Its ability to integrate with standard automation systems reduces complexity, allowing maintenance teams to monitor both safety and production status via a single HMI.

ABB SNAT634PAC

Related model recommendations

SNAT632PAC: A 8-channel variant of SNAT634PAC for smaller safety systems requiring fewer I/O points.

SNAT640PAC: A redundant safety controller with dual backplane connections, ideal for mission-critical applications needing 24/7 availability.

CB801 3BSE042245R1: ABB’s control board that integrates with SNAT634PAC for non-safety control functions.

DSDP140B: ABB’s digital input module used with safety relays to connect field devices to SNAT634PAC.

GRBTU 3BSE013175R1: ABB’s bus terminal unit that supports SNAT634PAC’s PROFIsafe communication.

HMI60-S: ABB’s safety-rated HMI panel that visualizes SNAT634PAC status and allows authorized users to reset safety alarms.

T840: ABB’s safety relay module that expands SNAT634PAC’s output capability for high-current devices (e.g., motor contactors).

Installation, commissioning and maintenance instructions

Installation preparation: Mount SNAT634PAC into a safety-rated backplane (compatible with GRBTU 3BSE013175R1), ensuring proper alignment with the connector. Secure with front-panel screws (torque to 0.8 Nm). Connect redundant 24 V DC power supplies (each 1A minimum) to the dedicated terminals, using separate circuits to ensure fault tolerance. Wire safety field devices to the channel terminals—use shielded twisted-pair cable (0.75mm²) for inputs/outputs, grounding shields at the module end. For communication, connect PROFIsafe (Cat 5e) and Modbus (shielded) cables. Required tools include a torque screwdriver, insulation tester (500 V DC), and a laptop with Safety Builder software. Power off all systems during installation.

Commissioning steps: Use Safety Builder to configure SNAT634PAC’s safety logic, defining channels as inputs/outputs and programming functions (e.g., emergency stop circuits, two-hand control). Validate the program using the software’s built-in verification tools to ensure compliance with SIL 3 requirements. Perform a full functional test by simulating fault conditions (e.g., disconnecting a safety input) and verifying the module triggers the correct safe state within 10 ms. Document all tests and obtain TÜV witness certification if required by local regulations. Save the safety program to secure memory with a password-protected backup.

Maintenance suggestions: Inspect SNAT634PAC quarterly for loose connections, dust accumulation, and LED status (power, safety, communication). Clean ventilation slots with compressed air—avoid using vacuum cleaners that generate static. Test safety functions annually by simulating faults (e.g., emergency stop activation) and verifying response times with a oscilloscope. Check firmware version biannually and update via secure Ethernet (with password authentication) to address security patches—never update firmware during production. If a safety fault is logged, perform a root-cause analysis and reset using Safety Builder; replace the module with an ABB-certified unit if hardware faults persist (do not repair field-replaceable units).

Service and guarantee commitment

SNAT634PAC comes with a 5-year warranty from installation, covering manufacturing defects and ensuring continued compliance with SIL 3/PLe certifications. ABB guarantees technical support response within 2 hours for safety-critical issues, with on-site service available in 48 hours for qualified industrial facilities. The module includes free access to Safety Builder software and safety-certified firmware updates for 5 years. Extended service contracts offer annual functional safety audits, TÜV-certified revalidation, and priority support, ensuring SNAT634PAC maintains safety integrity throughout its 15-year design lifespan. Customers receive dedicated online resources, including safety manual updates, certification documents, and troubleshooting guides specific to this model.