Description

Key Technical Specifications

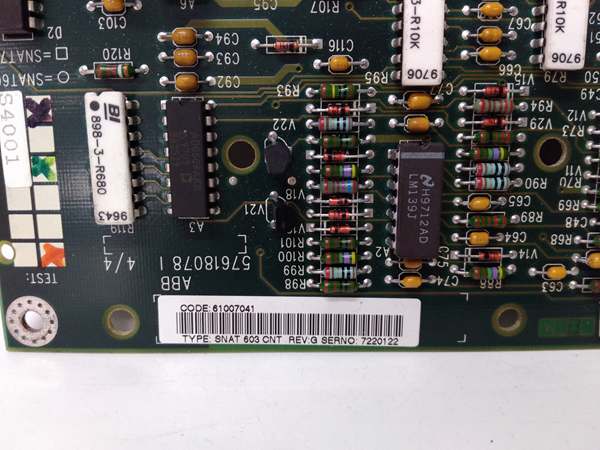

- Model Number: SNAT603CNT

- Manufacturer: ABB

- Protocol Support: Modbus RTU (master/slave configurable), RS-485 serial

- Wiring Configuration: 2-wire (half-duplex) or 4-wire (full-duplex), software-selectable

- Data Rate: 300 bps to 115.2 kbps (auto-baud detection compatible)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation: 2kV AC (bus to power supply, bus to backplane)

- Power Supply: 24V DC (100mA typical, derived from system backplane)

- Input/Output Impedance: 120Ω (RS-485 bus, switchable termination)

- Dimensions (W x H x D): 75mm x 125mm x 55mm

- Weight: Approx. 220g

- Mounting: DIN rail (35mm) or panel-mount (compatible with standard control cabinets)

- Protection Features: ESD protection (±15kV contact), surge protection (4kV), short-circuit tolerant

- Compliance: IEC 61000-4 (EMC), UL 508, CE, CSA C22.2

- Status Indicators: Power (PWR), TX/RX activity, bus fault, termination enabled

ABB SNAT603CNT

Field Application & Problem Solved

In process industries—refineries, chemical plants, and power stations—the biggest communication challenge is connecting legacy field devices (flow meters, pressure transmitters, valve positioners) to modern DCS/PLC systems amid high electromagnetic interference (EMI) and long cable runs. Traditional serial modules lack robust surge protection, suffer from signal corruption, or can’t switch between 2-wire/4-wire configurations, leading to data dropouts, misreadings, and unplanned downtime. This module solves that by combining flexible wiring, noise immunity, and rugged protection—creating a reliable link between field devices and central control.

You’ll typically find this module in DCS cabinets linking Modbus RTU-enabled devices to ABB AC 800M or similar controllers. In refineries, it connects tank level transmitters (located hundreds of meters from the control room) to the main DCS. In chemical plants, it links valve positioners in reactor loops to PLCs, ensuring precise control signal transmission. It’s also used in power plant auxiliary systems (e.g., cooling water pump controllers) and pulp mills (digester pressure sensors), where EMI from large motors and transformers is rampant. For retrofits, it’s a drop-in replacement for outdated RS-485 modules, upgrading protection and flexibility without reconfiguring existing field devices.

Its core value is adaptability and durability. The 2-wire/4-wire configurable design eliminates the need for separate modules for different bus architectures, reducing inventory costs. The built-in surge and ESD protection withstands voltage transients from lightning or motor startups, while the 2kV isolation prevents ground loops. For plant operators, this translates to consistent data flow, fewer communication-related faults, and easier troubleshooting—critical when bad data can lead to process upsets or safety hazards.

Installation & Maintenance Pitfalls (Expert Tips)

Wiring Configuration Mismatch

Rookies often wire a 2-wire field device to the module’s 4-wire setting (or vice versa), resulting in no communication. The module won’t auto-correct this—you must manually select 2-wire or 4-wire via DIP switches or software. Always check the field device’s wiring requirements first (most Modbus RTU sensors use 2-wire half-duplex). Test the configuration with a multimeter on the RS-485 terminals—no voltage on the bus indicates a wiring/configuration mismatch.

Termination Resistor: Know When to Enable

Forgetting to enable the 120Ω termination resistor (for 2-wire configurations) or enabling it on non-end nodes causes signal reflections. This leads to corrupted data in cable runs over 50m. Enable the resistor only on the first and last modules in the RS-485 bus. Use the module’s status LED to confirm termination is active—skip this, and you’ll waste hours diagnosing “intermittent” communication failures that only appear during peak system load.

Surge Protection: Don’t Bypass Shield Grounding

The module’s surge protection works best with proper cable shield grounding, but technicians often leave shields ungrounded or ground them at both ends. Ground the shield only at the module end (control cabinet side) to avoid ground loops that amplify EMI. For cable runs over 100m, use double-shielded twisted-pair cable—this enhances surge protection and reduces signal loss, especially in refineries or power plants with high EMI.

Data Rate & Parity Mismatch

A common mistake is setting the module’s baud rate, parity, or stop bits differently from the field device. Even a small mismatch (e.g., 9600bps vs. 19200bps) causes garbled data. Document the field device’s communication parameters first, then configure the module to match exactly. Use a Modbus scanner tool to verify communication after setup—this catches mismatches early and avoids costly process delays.

ABB SNAT603CNT

Technical Deep Dive & Overview

The ABB SNAT603CNT is a ruggedized RS-485 serial communication module designed to facilitate reliable data transfer between field devices and industrial control systems. At its core, it acts as a signal conditioner and protocol translator, converting Modbus RTU data between field devices and the central DCS/PLC while filtering out noise and protecting against electrical hazards.

The module’s flexible wiring (2-wire/4-wire) is enabled by internal switching circuitry, allowing it to adapt to both half-duplex (2-wire) and full-duplex (4-wire) RS-485 networks. The configurable data rate (300 bps to 115.2 kbps) ensures compatibility with legacy and modern devices alike, while auto-baud detection simplifies setup for devices with unknown parameters. Internally, a dedicated protection circuit guards against ESD (±15kV) and surge (4kV) events, common in industrial environments with unprotected wiring.

Communication with the central control system happens via the module’s backplane interface, ensuring fast data transfer without additional wiring. The 2kV isolation between the RS-485 bus and power supply/backplane prevents ground loops, a major source of signal corruption in distributed systems. The compact DIN rail design fits into space-constrained control cabinets, while the status LEDs (PWR, TX/RX, fault) provide at-a-glance visibility for troubleshooting.

What sets it apart is its no-nonsense reliability. It requires minimal configuration beyond wiring and parameter matching, making it ideal for both new installations and retrofits. The rugged components and wide operating temperature range ensure it performs consistently in harsh industrial conditions, from freezing power plant basements to hot refinery control rooms. Overall, it’s a workhorse module that prioritizes the core need of industrial communication: unbroken, accurate data transfer in unforgiving environments.