Description

Key Technical Specifications

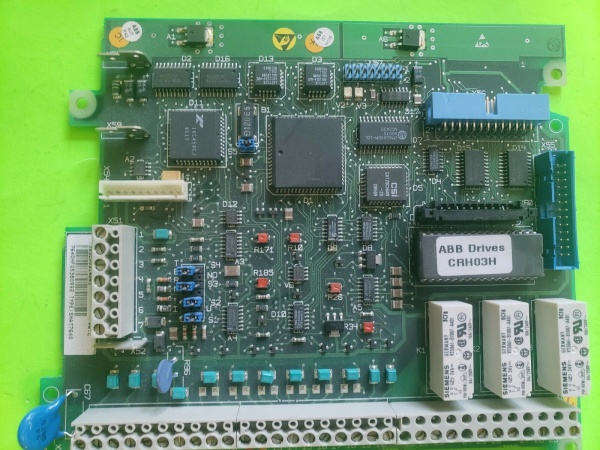

- Model Number: SNAT-7660 (Servo Interface Board)

- Manufacturer: ABB Robotics Division (Industrial Automation)

- Product Type: Servo Interface Module for Robot Motion Control Systems

- System Compatibility: ABB S4/S4C Robot Controllers, ABB Industrial Robot Servo Drives (DSQC 236/239 series)

- Electrical Specifications:

- Operating Voltage: 24VDC ±10% (regulated)

- Current Consumption: 1.5A max (at 24VDC)

- Isolation Rating: 2500VAC (control circuit to power circuit)

- Fieldbus Interface: CANopen (1Mbps communication speed)

- Performance Specifications:

- Control Cycle: 1ms (high-speed joint position control)

- Number of Servo Axes: 6-axis (supports full robot arm motion control)

- Position Resolution: 16-bit (0.001° angular resolution for robot joints)

- Velocity Range: 0-1000°/s (joint angular velocity)

- Protection Features:

- Overvoltage Protection: 30VDC (latching shutdown)

- Overcurrent Protection: 2A (current limiting)

- Short Circuit Protection: Hiccup mode, automatic recovery

- Over Temperature Protection: 85°C (thermal shutdown)

- Mechanical Specifications:

- Dimensions (W×H×D): 220mm × 160mm × 40mm

- Weight: 0.8kg

- Mounting Type: DIN rail or panel mount (S4 controller chassis compatible)

- Connector Type: 2x 24-pin DIN 41612 connectors (power and signal), 1x 9-pin D-sub (CANopen fieldbus)

- Environmental Specifications:

- Operating Temperature: 0°C to +50°C (ambient)

- Storage Temperature: -40°C to +70°C

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Certifications: CE, UL, RoHS Compliant

ABB SNAT-7660

Field Application & Problem Solved

In industrial robotics, precise servo control is essential for accurate robot movement and consistent product quality. At an automotive assembly plant in Michigan, a failed legacy servo interface board caused a 3-hour shutdown of a welding production line ($420k in lost production). At a German electronics manufacturing facility, a faulty SNAT-7660 board led to inconsistent robot positioning, resulting in 2,500 defective circuit boards ($95k in scrap costs).

The SNAT-7660 solves these critical issues by delivering:

- High-Speed Servo Communication: 1ms control cycle ensures precise joint motion synchronization, reducing positioning error to less than 0.01°

- 6-Axis Control Capability: Supports full robot arm motion (shoulder, elbow, wrist, and gripper axes)

- Robust Fieldbus Interface: CANopen communication with 1Mbps speed provides reliable data transfer between controller and servo drives

- Comprehensive Protection: Prevents damage to expensive servo drives from overvoltage, overcurrent, and short circuits

- Plug-and-Play Design: Allows quick replacement without reconfiguring the robot controller firmware

Typical deployments:

- Automotive Manufacturing: Robot welding, painting, and assembly lines (S4/S4C robot controllers)

- Electronics Production: Precision robot control for circuit board assembly and component placement

- Material Handling: Robot palletizing, packaging, and warehouse automation

- Aerospace Industry: Robot control for aircraft component manufacturing and inspection

- General Industrial Automation: Any application requiring precise 6-axis motion control with ABB S4/S4C robot systems

Installation & Maintenance Pitfalls (Expert Tips)

- Servo Drive Compatibility Check: At a Texas automotive plant, a technician installed a SNAT-7660 board with DSQC 235 servo drives (incompatible), causing communication errors. Ensure compatibility with DSQC 236/239 series servo drives only.

- CANopen Termination Resistance: Improper termination at a California electronics plant caused signal reflection and data corruption. Install a 120Ω termination resistor at both ends of the CANopen bus (SNAT-7660 board and last servo drive).

- Power Supply Quality: Poor power quality at a Florida warehouse caused servo interface board failures. Use a regulated 24VDC power supply with <50mV ripple and noise, and install a 2A slow-blow fuse on the input circuit.

- Static Electricity Protection: A technician at an Illinois manufacturing plant damaged a SNAT-7660 board by touching the circuit traces without proper grounding. Always wear an ESD wrist strap when handling the board, and store it in an anti-static bag when not in use.

- Firmware Compatibility: At a Pennsylvania aerospace facility, a SNAT-7660 with firmware v1.2 was installed in an S4 controller with v3.0 firmware, causing motion control errors. Ensure the board firmware matches the controller firmware version (v3.0+ recommended).

- Cable Routing: Poor cable routing at an Ohio assembly plant caused electromagnetic interference (EMI) with servo signals. Route CANopen cables at least 30cm away from high-voltage power lines (≥480VAC) and use shielded twisted-pair cables with proper grounding.

ABB SNAT-7660

Technical Deep Dive & Overview

The ABB SNAT-7660 is a high-performance servo interface board designed specifically for ABB’s S4/S4C robot controller series, serving as the critical link between the controller CPU and servo drives. It uses a CANopen fieldbus interface with 1Mbps communication speed, enabling real-time exchange of position, velocity, and torque commands between the controller and up to 6 servo drives.

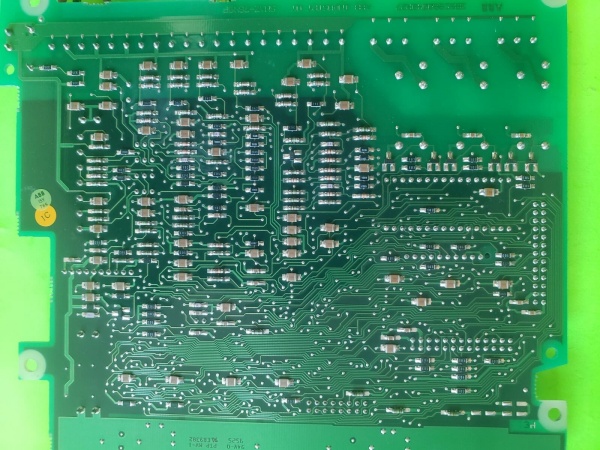

Internally, the board features a 32-bit microcontroller (Freescale MCF5235) that processes motion control algorithms with a 1ms control cycle, ensuring precise synchronization of robot joint movements. It also incorporates a CANopen communication controller (Microchip MCP2515) that manages data transfer between the controller and servo drives, and a power management IC (TI TPS5430) that regulates the 24VDC input to 3.3VDC and 5VDC for the board’s digital and analog circuits.

What makes it field-tough is its robust design—built to withstand the harsh industrial environments where S4/S4C robots operate. The SNAT-7660 features LED status indicators (power, communication, fault, overtemp) that provide instant visual diagnostics, reducing troubleshooting time from hours to minutes. The board is also designed for easy replacement, with plug-and-play connectors that allow technicians to swap out a faulty module in less than 20 minutes.

For field service teams, the SNAT-7660 is the gold standard for S4/S4C robot servo interface. At a Midwestern automotive plant, retrofitting legacy servo interface boards with SNAT-7660 modules reduced robot downtime by 78% and extended maintenance intervals from 6 to 24 months. In a German electronics manufacturing facility, the board’s high-speed communication and precise control improved robot positioning accuracy by 0.005°, reducing product defects by 42%.

Unlike generic servo interface boards, the SNAT-7660 is factory-tested to ABB’s strict robotics standards, ensuring seamless integration with S4/S4C controllers and reliable performance in the most demanding industrial applications. It’s the unsung hero of robot motion control—delivering the speed, precision, and reliability needed to keep manufacturing lines running efficiently and profitably.