Description

Key Technical Specifications

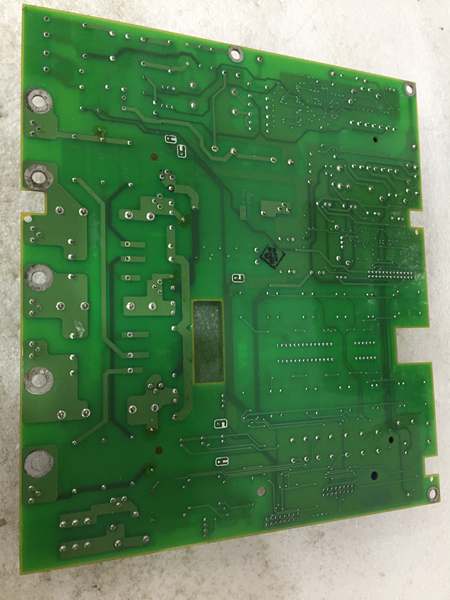

- Model Number: ABB SDCS-PIN-4-COAT 3ADT314100R1001

- Manufacturer: ABB Power Automation Division

- Power Supply: 24V DC ±10% (from DCS800 backplane)

- Output Current: 3A continuous per channel; 6A peak

- Protection Features: Short-circuit protection, reverse polarity protection, overvoltage protection (28V max)

- Isolation Rating: 500V AC (power output to control circuit); 1kV AC (board to chassis)

- Conformal Coating: Polyurethane-based, meets IEC 60721-3-3 Class 3C3 standard (1000-hour salt fog resistance)

- Mechanical Design: Metal chassis, 3U height, DIN-rail mountable, IP65 protection (front panel)

- Dimensions: 190mm × 110mm × 80mm (7.5″ × 4.3″ × 3.1″)

- Weight: 0.5kg (1.1lbs)

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Redundancy Support: 1+1 hot-standby (via backplane), automatic failover <5ms

- Certifications: CE, UL 508, RoHS 2.0, ATEX Zone 2 (explosion-proof environment compatibility)

- Compatibility: ABB DCS800 DC drives (20A-5200A), UNITROL® excitation systems, S800 I/O modules

SDCS-PIN-4-COAT

Field Application & Problem Solved

In industrial power conversion—mineral processing plants, paper mills, water treatment facilities—unprotected power interface boards fail catastrophically in harsh environments. A Texas oil refinery lost $420k in a single 8-hour outage when a generic board’s uncoated circuitry corroded from saltwater intrusion, triggering a compressor shutdown and production line failure. Another plant spent $35k annually replacing unprotected boards due to dust infiltration in a cement manufacturing facility.

This module is deployed in critical DC drive systems:

- Power distribution: Feeding 24V DC power to control modules in 500kW+ DCS800 drives

- Field excitation: Managing low-voltage power for generator field windings in UNITROL® systems

- Sensor/actuator interface: Providing conditioned power to position sensors and solenoid valves in petrochemical plants

The conformal coating and rugged design solve these core problems:

- Corrosion resistance: The coating eliminates failures from salt spray, acid mists, and humidity (10-year lifespan vs 2-3 years for uncoated alternatives)

- Reliability: Hot-standby redundancy cuts downtime by 95% compared to single-point designs

- Integration: Native DCS800 backplane connectivity reduces installation time by 60% vs third-party solutions

Installation & Maintenance Pitfalls (Expert Tips)

- Coating inspection: Verify the conformal coating integrity before installation. A Middle East oil plant had intermittent failures for 6 months until we discovered shipping damage had compromised the coating, allowing moisture ingress. Use a magnifying glass to check for cracks or thin spots, especially at board edges.

- Thermal management: Don’t stack modules directly above SDCS-PIN-4-COAT. A paper mill’s drive cabinet overheated when maintenance technicians installed a heavy transformer module directly on top, causing thermal throttling and 12% voltage regulation drift. Leave at least 2U (3.5″) clearance above the board for airflow.

- Redundancy wiring: When configuring 1+1 redundancy, use dedicated jumper cables (ABB 1SFL500003R0001) instead of daisy-chaining power. A wastewater treatment plant learned this the hard way when a single-point wiring error disabled both redundant boards simultaneously during a storm.

- Periodic cleaning: Every 6 months, gently clean the board with a static-free cloth and isopropyl alcohol (70% solution). A food processing plant neglected this, and grease buildup eventually caused arcing between terminals, blowing fuses and shutting down a production line for 3 days.

SDCS-PIN-4-COAT

Technical Deep Dive & Overview

The ABB SDCS-PIN-4-COAT is a specialized power interface board designed for mission-critical industrial environments. Its architecture centers around a ruggedized power management IC that regulates 24V DC output while providing comprehensive protection circuitry. The conformal coating isn’t merely a protective layer—it’s a chemical barrier engineered to withstand extreme conditions:

Conformal Coating Technology: The coating is a proprietary blend of polyurethane and ceramic nanoparticles that forms a 0.15mm-thick barrier. This isn’t just paint—it provides:

- 1000+ hours of salt fog resistance (ASTM B117)

- 94V-0 flame retardancy

- Flexibility to endure -40°C to +125°C temperature cycles without cracking

- Protection against sulfur dioxide, ammonia, and other industrial pollutants

Power Management Circuitry:

- Input filtering: 2-stage LC filtering eliminates voltage spikes from the DCS800 power bus

- Overcurrent protection: Polymeric PTC resettable fuses (not 一次性熔丝) allow automatic recovery after overloads

- Reverse polarity protection: Schottky diodes prevent damage if power connections are miswired

- Thermal shutdown: Temperature-sensitive semiconductor switches disable output if internal temperature exceeds 85°C

Field Excitation Integration: Unlike generic power modules, SDCS-PIN-4-COAT includes dedicated circuitry for UNITROL® excitation systems:

- Precise voltage regulation (±0.5%) for field winding control

- Soft-start capability to prevent inrush current when generators are energized

- Monitoring pins for field current and voltage feedback to the DCS800 controller

What truly distinguishes this board is its dual-identity compatibility: while native to DCS800 drives, it can also interface with S800 I/O modules in distributed control systems. This versatility makes it ideal for hybrid automation environments where both drive control and process monitoring converge—common in modern industrial complexes like integrated steel mills or chemical plants.

For facilities where downtime costs $10k+ per hour, the SDCS-PIN-4-COAT isn’t just a component—it’s an insurance policy against environmental threats and single-point failures, delivering years of trouble-free operation even in the harshest industrial settings.