Description

Key Technical Specifications

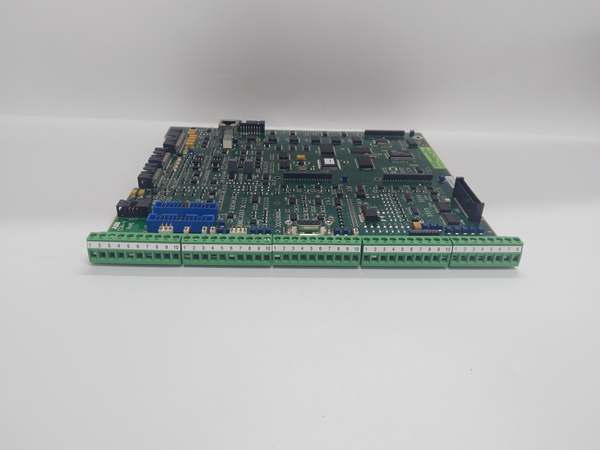

- Model Number: SDCS-CON-4

- Manufacturer: ABB

- Compatible Drives: ABB ACS800 Series Industrial Drives (all frame sizes)

- Protocol Support: Profibus DP, Modbus RTU, DeviceNet, Ethernet/IP (configurable via firmware)

- Communication Ports: 1 x Profibus DP (9-pin D-Sub), 1 x RS-485 (Modbus RTU), 1 x DeviceNet (5-pin M12), 1 x Ethernet (RJ45)

- Data Rate: Up to 12 Mbps (Profibus DP), 115.2 kbps (Modbus RTU), 100 Mbps (Ethernet/IP)

- Operating Temperature: -10°C to +60°C (14°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation: 2kV AC (communication ports to drive backplane)

- Power Supply: Derived from ACS800 drive backplane (24V DC, 200mA typical)

- Dimensions (W x H x D): 85mm x 150mm x 60mm

- Weight: Approx. 300g

- Mounting: Drive-integrated (plug-in to ACS800 drive control slot)

- Protection Features: ESD protection (±15kV), surge protection (4kV), short-circuit tolerance

- Compliance: IEC 61158 (fieldbus standards), IEC 61000-4 (EMC), UL 508C

- Status Indicators: Power (PWR), Protocol Activity (per port), Fault (RED), Link (Ethernet)

Field Application & Problem Solved

ABB SDCS-CON-4

In industrial settings—refineries, pulp mills, and manufacturing plants—the biggest challenge is integrating variable-frequency drives (VFDs) with existing PLC/DCS systems for centralized control and monitoring. Legacy drive communication modules suffer from protocol lock-in, slow data transfer, or poor compatibility with modern control systems, leading to disjointed operations, limited visibility into drive performance, and unplanned downtime. This module solves that by combining multi-protocol support with seamless ACS800 drive integration, eliminating the “communication silos” that plague mixed-control environments.

You’ll typically find this module installed in ACS800 drives powering critical equipment: refinery pump motors, pulp mill dryer section drives, or automotive assembly line conveyor motors. It’s also used in power plant auxiliary systems (e.g., fan drives) and chemical plant reactor agitator drives, where centralized control of speed, torque, and drive health is essential. For retrofits, it upgrades older ACS800 drives with modern communication capabilities, allowing integration with new PLC/DCS systems without replacing the entire drive—saving significant cost and installation time.

Its core value is flexibility and visibility. The multi-protocol design lets it connect to almost any industrial control network (Profibus, Modbus, Ethernet/IP), eliminating the need for custom gateways. Real-time data transfer (up to 100 Mbps via Ethernet) provides controllers with instant drive status (temperature, load, faults), while bidirectional communication enables remote drive configuration and tuning. For plant operators, this translates to centralized control over hundreds of drives, faster fault diagnosis, and reduced maintenance costs—critical in industries where drive downtime halts entire production lines.

Installation & Maintenance Pitfalls (Expert Tips)

Drive Slot Alignment: No Forced Insertion

Rookies often force the module into the ACS800 drive’s control slot, misaligning the backplane connector. Bent pins or partial seating cause intermittent communication drops or complete module failure. Align the module with the drive’s guide rails and slide it gently until it seats firmly—listen for a distinct “click.” Never tap or pry the module into place; damaged backplane pins require drive disassembly and costly repairs.

Protocol Configuration: Match Controller Settings

A common mistake is leaving the module’s default protocol (e.g., Profibus DP) active while the PLC uses Ethernet/IP. Mismatched protocols result in no communication, but diagnosing this takes hours. Use ABB’s DriveCom software to select the correct protocol for your control system. Verify baud rate, parity, and node address match the PLC/DCS settings—even a small discrepancy (e.g., Profibus address 5 vs. 6) will block data flow.

Ethernet Cable Selection: Avoid EMI in Industrial Environments

Technicians frequently use standard Cat5e cable for Ethernet/IP connections, ignoring EMI from nearby power cables or motor drives. This causes packet loss and slow communication. Use shielded Cat6 cable for Ethernet runs, and ground the shield at the control cabinet end. Keep Ethernet cables at least 20cm (8 inches) away from power cables—unshielded cables in high-EMI areas will experience 30%+ packet loss, leading to false drive fault alerts.

Neglecting Firmware Compatibility

Rookies skip updating the module’s firmware to match the ACS800 drive’s firmware version. Mismatched firmware causes communication glitches (e.g., dropped status updates) or complete protocol failure. Before installation, check the drive’s firmware version via the local HMI, then download the matching module firmware from ABB’s portal. Use DriveCom to flash the firmware—this takes 10 minutes but prevents months of intermittent issues.

ABB SDCS-CON-4

Technical Deep Dive & Overview

The ABB SDCS-CON-4 is a purpose-built communication interface module designed to integrate ABB ACS800 industrial drives with global industrial control systems. At its core, it acts as a protocol translator and data router, bridging the gap between the drive’s internal control bus and external PLC/DCS networks.

The module’s multi-protocol capability is enabled by a programmable firmware layer, allowing it to switch between Profibus DP, Modbus RTU, DeviceNet, and Ethernet/IP based on application needs. Each communication port operates independently, with dedicated signal conditioning and isolation (2kV AC) to prevent cross-talk and ground loop interference. High-speed Ethernet/IP support (100 Mbps) facilitates real-time drive monitoring and control, while legacy protocols (e.g., Modbus RTU) ensure compatibility with older control systems.

Powered directly from the ACS800 drive’s backplane, the module requires no external power supply, simplifying installation. Internally, protection circuits guard against ESD, surges, and short-circuits, extending lifespan in harsh industrial environments. The module communicates with the drive’s control board via a high-speed internal bus, accessing critical drive parameters (speed, current, temperature) and transmitting control commands (start/stop, speed setpoint) with minimal latency.

What sets it apart is its deep integration with ACS800 drives. Unlike third-party communication modules, it’s engineered to access the full range of drive data—including predictive maintenance alerts (e.g., bearing wear, winding temperature)—that generic modules can’t retrieve. The status LEDs provide at-a-glance visibility into port activity and faults, while diagnostic data is transmitted to the PLC/DCS for centralized monitoring. Overall, it’s a seamless extension of the ACS800 drive, designed to deliver reliable, flexible communication in the most demanding industrial control environments.