Description

Detailed parameter table

| Parameter Name | Parameter Value |

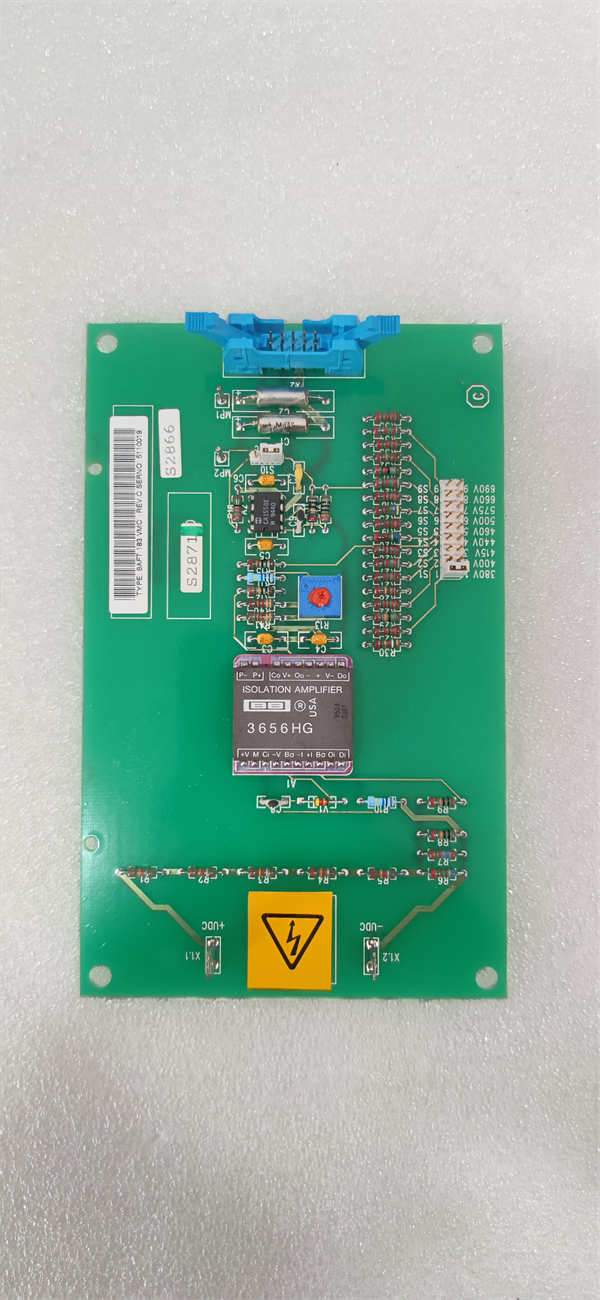

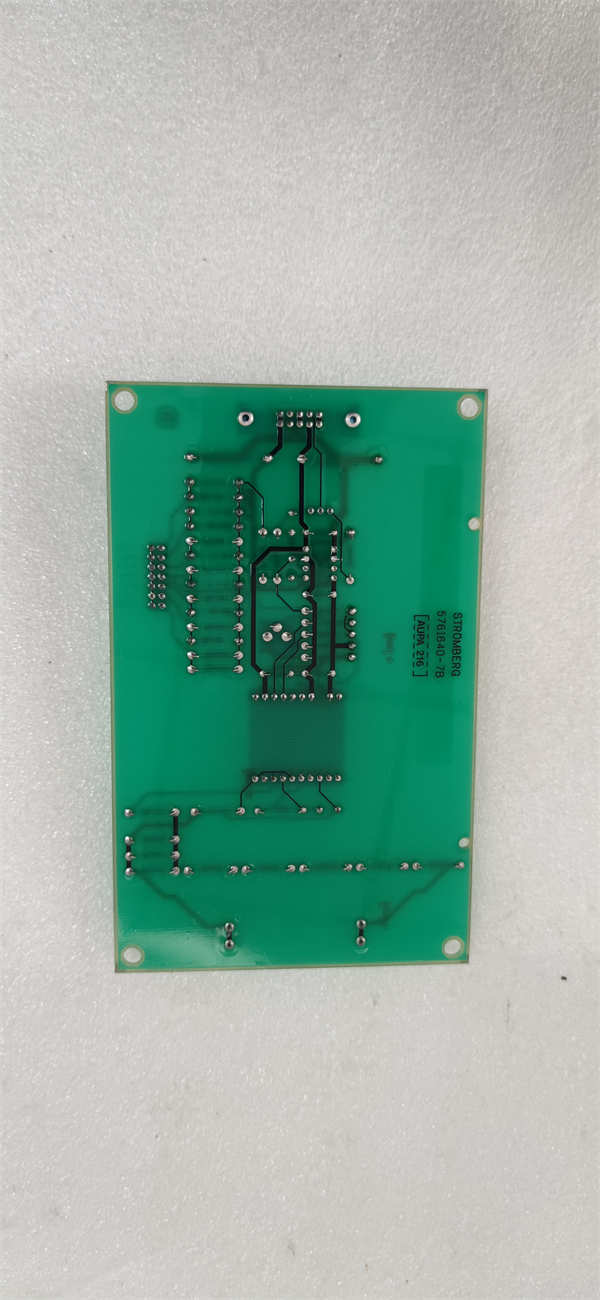

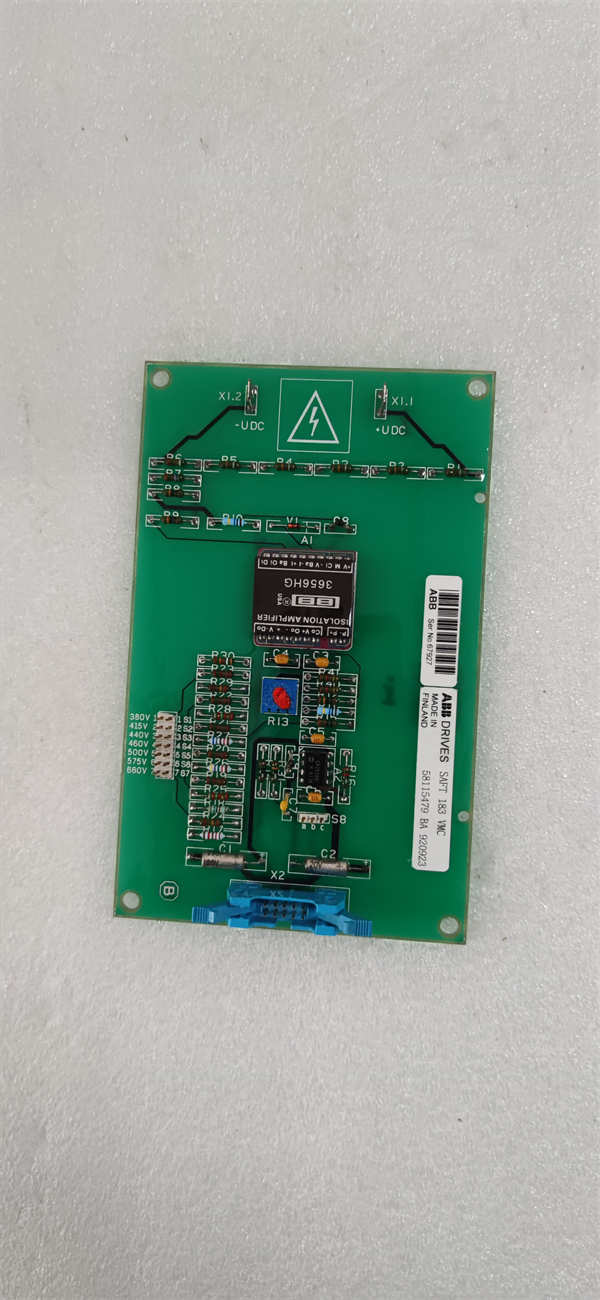

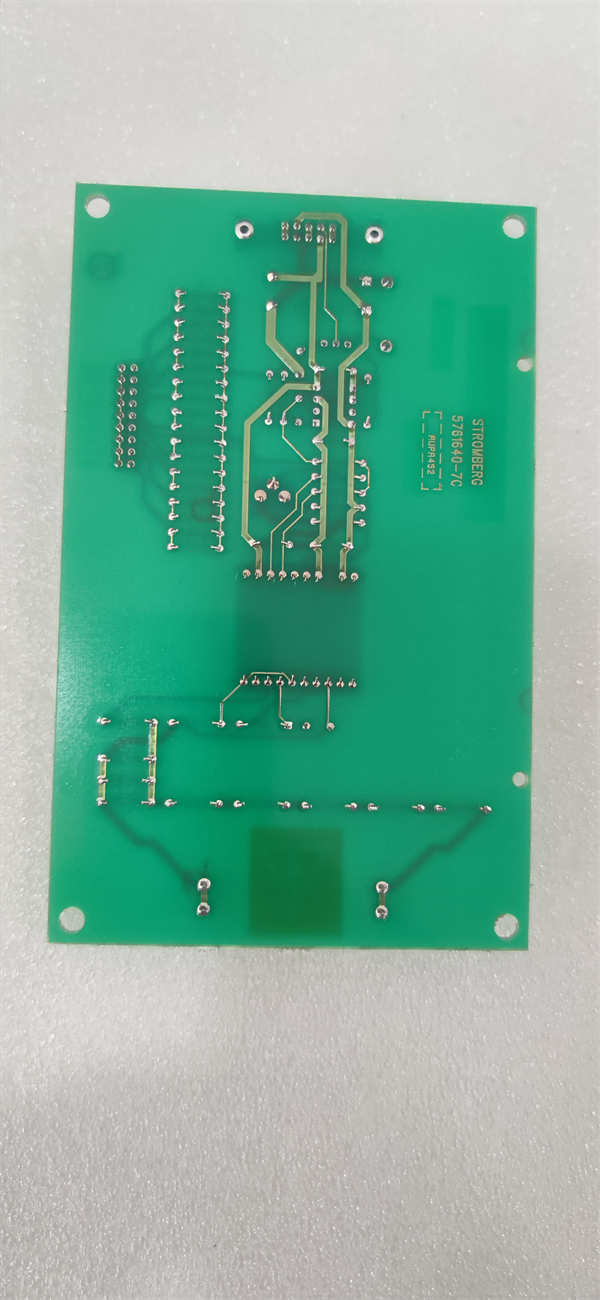

| Product Model | ABB SAFT183VMC |

| Manufacturer | ABB |

| Product Category | High-Integrity Safety Controller Module |

| Safety Certification | SIL 3 (IEC 61508), SIL 3 (IEC 62061), SIL 3 (IEC 61511) |

| Processor Architecture | Triple Modular Redundant (TMR) |

| Scan Time | ≤ 15 ms for safety-critical functions |

| I/O Capacity | Supports up to 1,024 safety I/O points |

| Communication Protocols | SafetyNET p, PROFIsafe, Modbus TCP (Safe) |

| Diagnostic Coverage | > 99% (per IEC 61508) |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Power Supply | 24 VDC (18-30 VDC), Redundant Inputs |

| MTBF | > 150 years (per IEC 61709) |

| Certifications | TÜV, EXida, ATEX/IECEx Zone 2 |

| Memory | 4 MB SRAM (voting memory), 16 MB Flash |

ABB SAFT183VMC

Product introduction

The ABB SAFT183VMC is a certified Triple Modular Redundant (TMR) safety controller within ABB’s premier High Integrity product line, engineered for mission-critical safety instrumented systems (SIS). Designed to achieve Safety Integrity Level 3 (SIL 3) across major international standards (IEC 61508, IEC 61511, IEC 62061), this module executes complex safety logic with deterministic reliability. As the core processing unit in ABB’s safety solutions, the SAFT183VMC provides fail-safe control for emergency shutdown (ESD), fire and gas (F&G), and machinery protection systems where human safety and asset protection are paramount.

Integrated within ABB’s System 800xA or deployable as a standalone safety controller, the ABB SAFT183VMC delivers continuous fault detection, automatic diagnostics, and voting-based error correction across three parallel processing channels. Its technical architecture prevents common-cause failures through physical separation, diverse compilers, and patented synchronization technology. The ABB SAFT183VMC fundamentally reduces risk in hazardous processes by enabling rigorous compliance with safety lifecycle requirements while maintaining operational availability through its fault-tolerant design.

Core advantages and technical highlights

The ABB SAFT183VMC sets the industry benchmark for functional safety through these critical advantages:

Uncompromising Safety Integrity: Achieving SIL 3 certification with diagnostic coverage exceeding 99%, the ABB SAFT183VMC employs rigorous TMR architecture. Three independent processors execute identical logic with continuous cross-comparison. Mismatches trigger automatic fail-safe responses without process interruption in 1oo2D or 2oo3 voting configurations. This inherent fault tolerance ensures no single point of failure compromises safety functions.

Advanced Diagnostic Capabilities: Beyond standard diagnostics, the ABB SAFT183VMC performs >200 automatic self-tests per second covering processor, memory, I/O communication, and power supply integrity. Real-time fault reporting through LED indicators and engineering software pinpoints issues before they affect performance. Predictive maintenance data reduces proof-testing frequency, lowering lifecycle costs.

Certified Network Safety: The ABB SAFT183VMC natively supports PROFIsafe and SafetyNET p protocols with embedded CRC checks, sequence numbering, and timeouts to prevent communication errors. This allows distributed safety I/O and devices (e.g., emergency stops, safety scanners) to connect over standard networks while maintaining SIL 3 integrity without additional gateways.

Seamless Engineering Integration: Configured using ABB’s Control Builder Safety (part of System 800xA), the ABB SAFT183VMC supports IEC 61131-3 languages with certified safety function blocks (FBs). The software automatically manages voting logic, diagnostics, and version control, reducing engineering errors and validation time by up to 40% compared to conventional safety PLCs.

Extreme Environmental Robustness: Engineered for deployment in harsh conditions, the ABB SAFT183VMC operates reliably across -40°C to +70°C with 95% non-condensing humidity. Its conformal-coated electronics withstand corrosive atmospheres, while ATEX/IECEx Zone 2 certification enables installation in hazardous areas. The 150-year MTBF demonstrates exceptional long-term reliability.

Typical application scenarios

The ABB SAFT183VMC is indispensable in industries where catastrophic failures carry severe consequences. In oil and gas refineries, it serves as the backbone for Emergency Shutdown Systems (ESD), executing complex trip logic for furnace shutdowns, compressor protection, and wellhead control during overpressure or gas detection events. Its TMR design ensures zero nuisance trips while guaranteeing fail-safe operation during emergencies, directly protecting personnel and multi-million-dollar assets.

Within chemical processing plants, the ABB SAFT183VMC manages critical Burner Management Systems (BMS), providing SIL 3-certified flame supervision, purge sequencing, and valve leak testing. It integrates with flame scanners and gas detectors to prevent explosions in reactors and storage facilities. The module is equally vital in power generation for turbine overspeed protection and boiler safety interlocks, and in pharmaceutical manufacturing where it ensures aseptic processing containment through safety-rated door interlocks and pressure cascades. For automated machinery, the ABB SAFT183VMC provides SIL 3 protection for robotic cells, press brakes, and high-speed conveyors through safety door monitoring and light curtain integration.

ABB SAFT183VMC

Related model recommendations

ABB SD822/SD823: SIL 3-certified digital input/output modules designed for direct integration with the SAFT183VMC.

ABB AI830/AO810: SIL 2/3 analog input/output modules for safety-critical process monitoring and control.

ABB CI865: Safety communication interface for PROFIsafe integration with third-party devices.

ABB PP825: Redundant power supply unit certified for use with SAFT183VMC systems.

ABB CP600-S: Safety operator panels with emergency stop functionality for SAFT183VMC systems.

ABB SCY21650: Safety relay modules for hardwired backup of critical SAFT183VMC functions.

ABB XIO-08/16: Expansion I/O units for distributed safety applications using SAFT183VMC.

ABB Control Builder Safety: Mandatory engineering software for SIL 3 programming and validation.

ABB COM600: Substation computer that interfaces with SAFT183VMC for electrical safety systems.

ABB S800 I/O with HI Option: High-Integrity base units for local SAFT183VMC I/O mounting.

Installation, commissioning and maintenance instructions

Installation Preparation: Before installing the ABB SAFT183VMC, verify the cabinet environment meets temperature, humidity, and cleanliness specifications. Ensure certified redundant 24VDC power supplies with adequate derating (minimum 20% headroom). Required tools include calibrated torque screwdrivers (for terminal blocks), ESD protection gear, and ABB-approved crimping tools. Review safety validation plans (SVP) and cause-and-effect diagrams. Critical precautions: Implement lockout/tagout (LOTO) for all energy sources, use ABB-qualified base units (e.g., PP825), maintain minimum clearance for ventilation, and strictly follow grounding specifications in the Safety Manual.

Maintenance Suggestions: Perform quarterly visual inspections of the SAFT183VMC for dust accumulation (clean with nitrogen blow-off), connector integrity, and LED status. Annually verify power supply voltages and grounding resistance. Use Control Builder Safety for monthly diagnostic log reviews and predictive failure analysis. Maintain cryptographic module signatures for firmware integrity. During module replacement (use only ABB-certified spares), follow safe change procedures per ANSI/ISA 62443, including application backup, configuration verification, and functional safety testing post-installation. Never bypass diagnostics or force safety signals.

Service and guarantee commitment

ABB guarantees the functional safety and performance of the ABB SAFT183VMC through a comprehensive 18-month warranty covering materials and workmanship, extendable via service agreements. Our Safety Excellence Centers provide 24/7 global support with TÜV-certified functional safety experts (TÜV FSEng) for urgent diagnostics, spares logistics, and SIL validation support. ABB delivers lifecycle services including:

Safety lifecycle audits and SIL verification studies

On-demand firmware updates with version control

Certified repair services with traceable recalibration

Migration planning from legacy safety systems

Functional safety training (IEC 61511 compliance)

All services comply with IEC 61508/IEC 61511 requirements, ensuring your ABB SAFT183VMC maintains certified safety integrity throughout its operational lifetime.