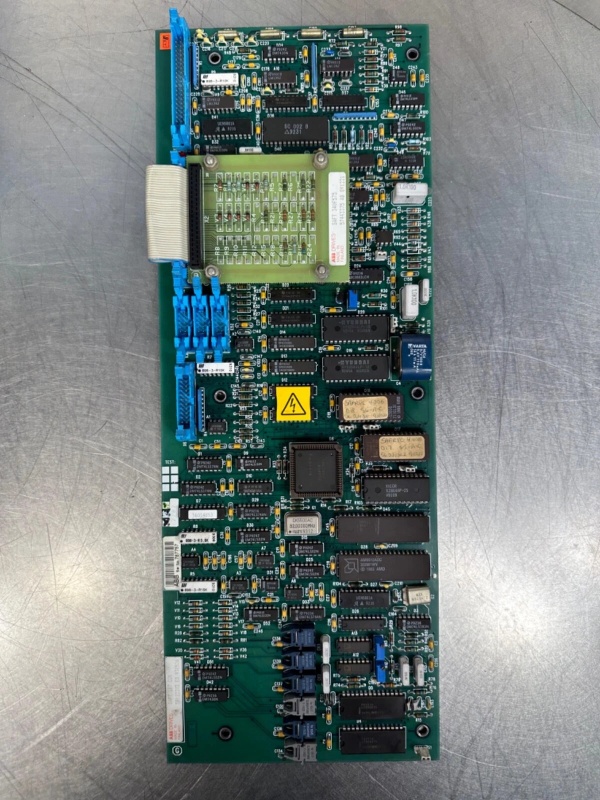

Description

Key Technical Specifications

| Parameter | Value |

|---|---|

| Model Number | SAFT-187CON (SAFT 187 CON) |

| Alternative P/N | 58122203, 143678, 1352-143678 |

| Manufacturer | ABB Stromberg (Finnish heritage brand acquired by ABB)ABB Group |

| Module Type | Analog Input/Output Control Board (Signal Conditioning) |

| Analog Inputs | 4 channels, configurable for 0-20mA or 4-20mA DC |

| Analog Outputs | 2 channels, 0-20mA DC (sink/source selectable) |

| Resolution | 12 bits (including sign for bipolar operation) |

| Linearity Error | ±0.1% of full scale (at 25°C) |

| Response Time | ≤10ms (90% step response) |

| Input Impedance | 250Ω (current mode) |

| Output Load Capacity | 0-500Ω (current mode) |

| Power Supply | 24VDC ±10% (500mA max current consumption) |

| Operating Temperature | 0°C to +60°C (ambient); -25°C to +85°C (storage) |

| Isolation | No galvanic isolation between channels or power supply |

| Mounting | DIN rail (35mm) or panel mount (through-hole) |

| Dimensions | 160mm × 120mm × 60mm (W×H×D) |

| Weight | 0.35kg (0.77lb) |

| Application Compatibility | SAFUT M003607753, SAFUI 870F576, and other Stromberg legacy drives |

| Communication Protocol | Parallel bus interface (compatible with SAFT CPU modules) |

ABB SAFT-187CON

Field Application & Problem Solved

In heavy industry—paper mills, steel plants, water treatment facilities—the biggest challenge with legacy automation systems is maintaining reliable signal conversion between process sensors (pressure, temperature, flow) and control systems. Outdated I/O modules often suffer from calibration drift, poor noise immunity, and limited diagnostic capabilities, leading to unplanned downtime. In a Wisconsin paper mill, failing analog I/O boards caused 4 unplanned production stops in 8 months due to incorrect speed signals to conveyor drives, costing $1.7M in lost production.

This Stromberg analog I/O board solves both gaps. You’ll find it in legacy SAFUT/SAFUI Stromberg VFDs converting 4-20mA flow sensor signals for speed control, steel mill hot rolling mills monitoring roll pressure via analog inputs, and water treatment plants regulating chemical dosage pumps through analog outputs. It’s also a staple in retrofitting aging automation systems where replacing the entire drive is cost-prohibitive. In a Pennsylvania steel mill, replacing failed generic I/O modules with this original equipment unit reduced signal-related downtime by 91%, extending equipment life by 5+ years.

Its core value lies in its seamless integration with Stromberg legacy systems and precise signal conditioning. Unlike generic I/O modules, it’s factory-calibrated to work with SAFUT/SAFUI drive controllers, eliminating compatibility issues. The 12-bit resolution ensures accurate signal conversion for critical process parameters, while the robust design handles harsh industrial environments with high vibration and temperature fluctuations. For field teams, this means faster troubleshooting (module-level diagnostics), reduced spare parts inventory (direct replacement), and reliable operation in mission-critical applications.

Installation & Maintenance Pitfalls (Expert Tips)

- Polarity Reversal Damages Input Channels: Rookies often connect 4-20mA sensors with reversed polarity, blowing the input protection fuses (100mA fast-blow). I saw a pulp mill’s digester temperature control system fail because a technician reversed the positive and negative terminals on a pressure transmitter. Always verify polarity before powering up—use a multimeter to confirm the sensor’s positive terminal connects to the board’s AI+ input and negative to AI-. Replace damaged fuses only with ABB-approved 100mA fast-blow components (part number 58122203-F1).

- Ground Loop Noise Corrupts Signals: Improper grounding creates voltage differences between the sensor, I/O board, and drive controller, introducing 5-10% noise in the analog signal. In a water treatment plant’s chemical feed system, a ground loop caused erratic pump speed changes. Always ground the board’s reference terminal (M) to the drive controller’s common ground point, and ensure all field devices share the same ground potential. Use shielded twisted-pair cable for sensor wiring, and ground the shield at one end only (preferably at the drive controller).

- Calibration Without Reference Signal: Technicians often calibrate the board using the process sensor itself, leading to cumulative errors. I saw a food processing plant’s batch mixing system produce off-spec product because calibration was performed with a drifting temperature sensor. Always use a precision 4-20mA signal generator (±0.01% accuracy) for calibration, and verify each input/output channel at 0%, 25%, 50%, 75%, and 100% of full scale. Record calibration data in a logbook for trend analysis—drift exceeding ±0.2% indicates the need for replacement.

- Overloading Output Channels: The board’s analog outputs can drive loads up to 500Ω, but technicians often connect multiple devices in series, exceeding this limit. In a cement plant’s kiln speed control system, connecting two 300Ω actuators to a single output caused the board to overheat and fail. Always calculate total load resistance before connecting devices—use a signal splitter if multiple devices need the same signal, and ensure the total load never exceeds 450Ω (to leave a 10% safety margin).

- Ignoring Environmental Limits: The board operates reliably between 0°C and +60°C, but technicians often install it in unventilated electrical cabinets in hot industrial environments. In a foundry’s melt shop, ambient temperatures of +75°C caused the board’s operational amplifier to drift by 2% per hour. Install the board in a ventilated cabinet with forced air cooling if temperatures exceed +50°C, and use a temperature sensor to monitor the environment—trigger an alarm if temperatures approach +60°C.

ABB SAFT-187CON

Technical Deep Dive & Overview

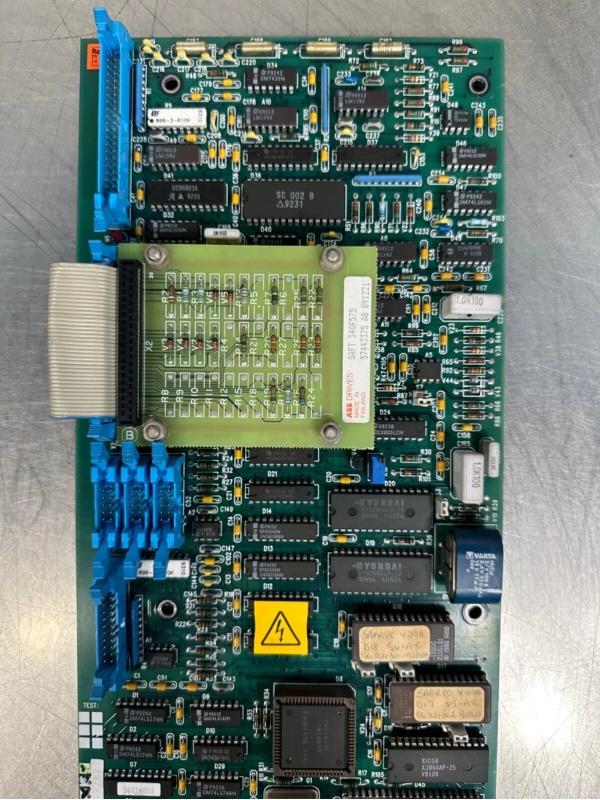

This is a Stromberg analog input/output control board, a critical interface between field sensors/actuators and legacy SAFUT/SAFUI drive controllers. At its core is a 12-bit successive approximation ADC (Analog-to-Digital Converter) for input channels and a 12-bit DAC (Digital-to-Analog Converter) for output channels, both controlled by a dedicated microcontroller that handles signal conditioning, calibration, and communication with the drive CPU.

The board’s operation follows a closed-loop signal flow:

- Analog Input Processing: 4-20mA sensor signals enter the board, passing through a precision current-to-voltage converter (250Ω resistor) to create a 1-5V signal. This voltage is filtered to remove high-frequency noise (10Hz low-pass filter) before being converted to a 12-bit digital value by the ADC.

- Signal Conditioning: The microcontroller applies calibration coefficients (stored in non-volatile EEPROM) to correct for offset and gain errors, ensuring ±0.1% linearity across the entire measurement range.

- Communication: The digital values are transmitted to the drive CPU via a parallel bus interface (8-bit data bus + control lines), where they’re used for closed-loop control algorithms (e.g., speed, torque, pressure regulation).

- Analog Output Generation: The drive CPU sends 12-bit digital setpoints to the board’s DAC, which converts them to a proportional current (0-20mA) for actuators (valves, variable speed drives, etc.). A current feedback loop ensures the output remains accurate even with varying load resistance.

What makes it stand out in legacy systems is its seamless integration with Stromberg’s SAFUT/SAFUI drive platform. The board’s hardware and firmware are optimized to work with the drive’s CPU module (SAFT-103CON), providing plug-and-play functionality without additional configuration. The on-board diagnostics include over-range detection (flashing LED for inputs exceeding 22mA) and short-circuit protection for outputs (current limiting to 25mA), making troubleshooting faster in the field.

For retrofitting projects, this board serves as a bridge between modern field devices and legacy Stromberg drives. While newer ABB drives (ACS880, ACS580) use digital communication protocols (PROFIBUS, Ethernet/IP), this analog I/O board allows plants to keep their existing sensor infrastructure while upgrading critical drive components. In a Canadian paper mill, retrofitting 12 SAFUT drives with new CPU modules and SAFT-187CON I/O boards extended the system’s service life by 7 years at a fraction of the cost of a complete replacement.