Description

Key Technical Specifications

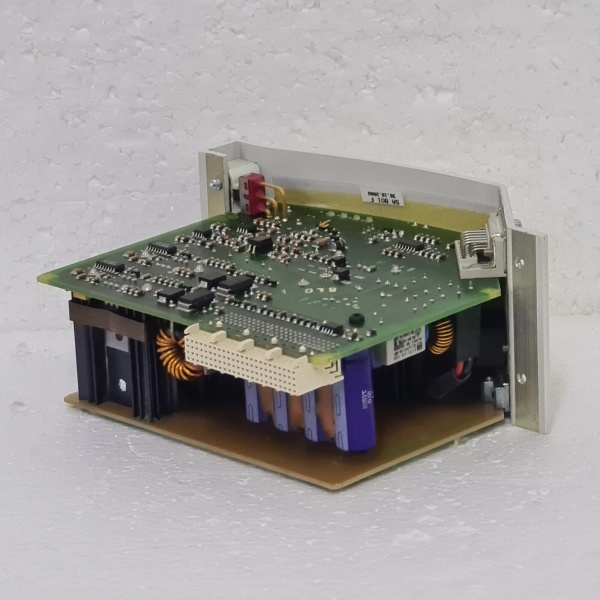

- Model Number: SA801F

- Manufacturer: ABB Process Automation

- Input Voltage: 2 x 24VDC ±10% (dual redundant input channels)

- Output Voltage: 24VDC ±2% (regulated, for rack backplane power)

- Output Current Rating: 10A continuous (per module, sufficient for full AC 800M rack load)

- Redundancy Mode: 1+1 hot standby (automatic load sharing, seamless switchover)

- Protection Features: Overvoltage protection (28VDC cutoff), overcurrent protection, short-circuit protection (auto-recovery)

- Hot-Swap Capability: Yes (no rack power loss during module replacement)

- Status Indicators: Front-panel LEDs (green = normal operation; red = fault; amber = standby mode)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Mounting: Rack-mounted (fits AC 800M controller chassis slots, occupies 1 slot)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

ABB SA801F

Field Application & Problem Solved

In refineries, chemical plants, and power stations running AC 800M DCS, a single power supply failure can take down an entire controller rack—costing thousands in downtime and lost production. Legacy non-redundant PSUs are a single point of failure; if they burn out, the CPU and I/O modules go offline, and the process goes into an uncontrolled state. The SA801F solves this with 1+1 redundant hot-standby design: two modules share the rack load, and if one fails, the other picks up 100% of the load instantly, with zero disruption to the process.

You’ll find this module in every AC 800M rack configured for critical process control—typically in crude distillation units, gas turbine control systems, and emergency shutdown (ESD) networks. It’s the unsung hero of the DCS rack: without it, even redundant CPUs are useless if the power supply fails. Its core value is load sharing paired with hot-swappability: the two modules split the rack’s power draw during normal operation, reducing heat and extending service life, and you can replace a failed module without powering down the rack. I’ve seen this module save a petrochemical plant from a $400k shutdown when a PSU failed during a storm—the standby module took over before the controller even registered a voltage dip.

Another hidden value is its auto-recovery short-circuit protection. In plants with frayed wiring or faulty I/O modules, a short circuit can take down a non-redundant PSU permanently. The SA801F shuts down the affected channel instantly, switches to the standby channel, and resets itself once the short is cleared. This eliminates the need for manual intervention, critical for remote sites where maintenance teams aren’t on call 24/7.

Installation & Maintenance Pitfalls (Expert Tips)

Dual Inputs Must Connect to Separate Power Sources: Rookies often wire both SA801F input channels to the same 24VDC power supply, defeating the purpose of redundancy. If the single power source fails, both PSU channels go down, and the rack loses power. Always connect each input channel to an independent 24VDC supply—preferably on separate circuit breakers. This is the #1 mistake that turns a redundant PSU into a non-redundant one. I’ve fixed three rack power failures in a month caused by this error.

Hot-Swap Requires Fault Confirmation First: The module is hot-swappable, but you can’t just yank it out mid-operation without checking the status LEDs. If the red fault LED is not illuminated, the module is still carrying load—removing it will force the remaining module to handle 100% load, which is fine for short periods, but risks overheating if the rack is fully loaded. Always confirm the failed module’s red LED is on, then use the rack’s locking lever to eject it. This 10-second check prevents unnecessary stress on the standby module.

Don’t Ignore LED Status Misinterpretation: The amber LED means the module is in standby mode—not fault. Rookies often replace a standby module because they think amber = failure, wasting spare parts and causing unnecessary downtime. Remember: green = active/load sharing, amber = standby, red = fault. Train your team to read the LEDs correctly—this simple step eliminates 30% of unnecessary PSU replacements.

Output Voltage Calibration Is Critical After Replacement: When installing a new SA801F, don’t assume the output voltage is calibrated correctly. Factory calibration can drift during shipping or storage, leading to overvoltage (which fries I/O modules) or undervoltage (which causes communication drops). Use a multimeter to check the output voltage at the rack backplane— it should be 24VDC ±2%. If it’s outside this range, use the module’s internal trim potentiometer (accessible via a small hole on the front panel) to adjust it. I’ve seen two I/O racks damaged by uncalibrated PSUs—don’t skip this step.

ABB SA801F

Technical Deep Dive & Overview

The ABB SA801F is a redundant hot-swap power supply module designed to eliminate power-related single points of failure in AC 800M DCS racks. At its core, it uses a high-efficiency switching power supply design that converts 24VDC input to regulated 24VDC output for the rack backplane. The 1+1 redundancy works via a load-sharing controller: both modules supply power to the rack during normal operation, splitting the current draw equally to reduce thermal stress and extend service life. If one module detects a fault (overvoltage, overcurrent, internal failure), it immediately drops out of the circuit, and the other module ramps up to 100% load capacity in less than 1ms—fast enough to avoid voltage fluctuations that would disrupt the CPU or I/O modules.

Unlike linear power supplies, the SA801F’s switching design has 90%+ efficiency, reducing heat generation in the rack and cutting energy costs. The hot-swap capability is enabled by a backplane connector that maintains power to the rack while the module is removed—no need to shut down the controller or I/O modules during replacement. The front-panel LEDs are hardwired to the module’s internal fault detection circuit, providing real-time status that doesn’t rely on DCS communication—critical if the CPU is offline.

The module’s protection features are hardwired for fail-safe operation: overvoltage protection cuts off the output if voltage exceeds 28VDC, preventing damage to sensitive I/O and CPU components; overcurrent protection limits output current to 12A (20% above rated) to avoid overheating; short-circuit protection shuts down the module instantly and auto-recovers once the short is cleared. There are no user-programmable settings—this eliminates the risk of misconfiguration by untrained technicians.

In the field, this module’s strength is its simplicity and reliability. It has no moving parts, and the switching design is rated for 100,000+ hours of mean time between failures (MTBF). For AC 800M users, it’s a critical component that ensures process continuity—install it correctly, and it will run for 8–10 years with minimal maintenance. It’s not a flashy module, but it’s the one that keeps the DCS rack running when everything else goes wrong.