Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | SA801F |

| Manufacturer | ABB |

| Product Category | Safety Relay Module |

| Input Voltage | 24 V DC (19.2–28.8 V DC) |

| Number of Channels | 8 independent safety channels |

| Safety Certification | SIL 3 (IEC 61508), PLe (ISO 13849-1), Cat. 4 |

| Response Time | ≤ 1.2 ms per channel |

| Operating Temperature | -25°C to +60°C (derating above 40°C) |

| Housing Material | Polycarbonate (UL94 V-0 rated) |

| Dimensions (WxHxD) | 12.5 x 116 x 117 mm |

| Interface Type | Spring-cage clamping (screwless) |

| Communication | Via AC500 PLC backplane (safety protocol) |

| Diagnostics Coverage | > 99% (internal self-monitoring) |

| MTTFd | > 100 years |

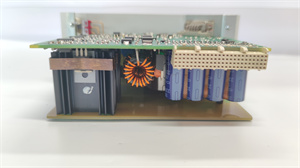

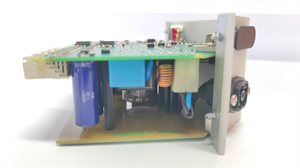

ABB SA801F

Product Introduction

The ABB SA801F is a high-integrity safety relay module designed for integration into ABB’s AC500 programmable logic controller (PLC) systems. As part of ABB’s certified safety solution portfolio, this module provides critical safety input processing for emergency stops, safety gates, light curtains, and other safety devices in industrial machinery. The ABB SA801F converts signals from up to eight dual-channel safety sensors or switches into a fail-safe logic evaluated by the safety CPU.

Engineered for functional safety compliance, the ABB SA801F enables the construction of safety systems meeting SIL 3 (IEC 61508), Performance Level e (ISO 13849-1), and Category 4 requirements. Its core function is to reliably detect faults in wired safety circuits (e.g., short circuits, wire breaks, contact welding) through continuous cross-monitoring and internal diagnostics. Integration into the AC500 platform allows unified programming and diagnostics via ABB’s Automation Builder engineering suite, streamlining safety system design. The ABB SA801F ensures personnel protection and machine availability by providing deterministic, fault-tolerant response in critical control scenarios.

Core Advantages and Technical Highlights

ABB SA801F sets the benchmark for safety and reliability in industrial automation:

Ultra-Fast Fault Detection: With a response time under 1.2ms per channel, the ABB SA801F minimizes machine downtime while ensuring immediate reaction to safety events. Its patented diagnostic algorithms detect wiring faults (cross-circuits, shorts to ground/voltage) within a single PLC cycle, exceeding industry norms for diagnostic coverage (>99%).

Seamless System Integration: Designed natively for the AC500 PLC platform, the ABB SA801F shares backplane communication with standard I/O and CPUs. This eliminates complex gateway configurations, allowing unified programming, monitoring, and diagnostics in Automation Builder. Safety logic and standard control logic coexist in a single engineering environment, reducing commissioning time by up to 40%.

Robust Environmental Tolerance: Operating reliably from -25°C to +60°C with high resistance to vibration (up to 5g) and electrical noise (EN 61000-6-2/-4), the ABB SA801F performs in harsh industrial environments like foundries or material handling. Its flame-retardant polycarbonate housing and screwless spring-clamp terminals ensure long-term connection integrity, even in dusty or humid conditions.

Future-Proof Flexibility: The module supports diverse safety device types (e.g., OSSD, NAMUR, mechanical contacts) without external adapters. Hot-swappable design enables module replacement without system shutdown, while SIL 3 certification simplifies validation for global safety standards compliance.

Typical Application Scenarios

The ABB SA801F excels in safety-critical automation across heavy industries:

In automotive manufacturing, the ABB SA801F monitors robotic cell safety gates, light curtains, and emergency stops. Its fast response ensures immediate halting of robots during human intrusion, preventing accidents while minimizing production interruptions. The module’s ability to handle multiple zones within a single PLC rack reduces cabinet footprint in space-constrained assembly lines.

For packaging machinery, the ABB SA801F interfaces with servo-driven cutter guards and conveyor interlocks. Its diagnostics detect contact welding on solenoid locks, preventing unintended restarts during maintenance. In pharmaceutical plants requiring SIL 2+/SIL 3 safety loops for reactor pressure relief systems, the ABB SA801F provides certified input processing with full audit trails via Automation Builder.

Material handling systems (e.g., AS/RS cranes) leverage the ABB SA801F for overspeed detection and hoist limit switches. Its high MTTFd (>100 years) ensures operational integrity in 24/7 logistics centers, while derating guidance for high ambient temperatures (+60°C) allows deployment in warehouse rooftops without derating safety performance.

ABB SA801F

Related Model Recommendations

AC500-S CM579F: Safety CPU for SIL 3 applications; executes safety logic from SA801F inputs.

SA821F: Complementary safety output module; drives safety contactors/valves based on SA801F signals.

SA711F: Safe encoder interface module; provides speed monitoring for drives paired with SA801F emergency stops.

AC500 PM591: Standard PLC CPU; coordinates non-safety processes with SA801F-protected zones.

SD821: Digital output module; controls machine peripherals adjacent to SA801F in the same rack.

AXL F DI8/1 DO8/1: Remote I/O safety module; extends SA801F capabilities via PROFIsafe/PROFINET.

AC500 eXtended Safety: Software license for programming SA801F logic in Automation Builder.

ABB 1SFL281001R1000: Redundant power supply; ensures 24V DC integrity for SA801F critical loads.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Ensure the AC500 baseplate is securely mounted and powered off. Verify ambient temperature (<60°C) and humidity (<95% non-condensing). Use ABB-approved DIN rail clips (ART. 3HAC042197-001). A torque-limited screwdriver (0.6 Nm) is recommended for terminal blocks if retrofitting wired devices. Disconnect all field power before inserting the ABB SA801F into the slot.

Maintenance Suggestions:

Perform quarterly visual inspections for dust accumulation or terminal discoloration. Use Automation Builder’s diagnostic buffer to log channel faults – recurring errors may indicate wiring degradation. Replace the ABB SA801F module if the STATUS LED flashes red. Always use ABB-certified spare parts (e.g., terminal covers 1SBP260200R1001) to maintain safety ratings. Clear the PLC’s fault memory after maintenance to reset diagnostic counters.

Service and Guarantee Commitment

ABB stands behind the SA801F with a 36-month global warranty covering defects in materials and workmanship. Our Technical Support Centers provide 24/7 assistance for troubleshooting, backed by ABB’s Safety Engineering Services for SIL validation support. All ABB SA801F modules undergo rigorous end-of-line testing, including HALT (Highly Accelerated Life Testing) to ensure field reliability. Firmware updates are provided free of charge via the Automation Builder platform. Extended service agreements (ESA) offer on-site repair, calibration, and lifecycle management beyond the warranty period. ABB’s functional safety experts deliver certified training for installers and integrators to maximize system uptime.