Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | S-053M 3BHB012897R0003 |

| Manufacturer | ABB |

| Product category | Industrial signal processing module (for control systems) |

| Input signals | 8 x analog inputs (4-20 mA, 0-10 V DC) |

| Output signals | 4 x analog outputs (4-20 mA, 0-10 V DC) |

| Signal resolution | 16-bit (input and output) |

| Accuracy | ±0.1% of full scale |

| Isolation rating | 2.5 kV AC (channel to backplane) |

| Communication protocol | MODBUS RTU |

| Operating voltage | 24 V DC ±10% |

| Power consumption | Max 3 W |

| Operating temperature | -20°C to 60°C |

| Protection rating | IP20 |

| Mounting type | DIN rail (35mm) |

| Dimensions | 95mm × 150mm × 35mm |

| Certifications | IEC 61131-2, CE, UL, RoHS |

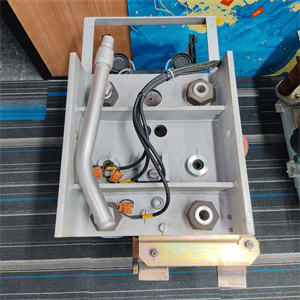

ABB S-053M 3BHB012897R0003

Product introduction

The S-053M 3BHB012897R0003 is a high-precision signal processing module from ABB, designed to serve as a critical interface between field sensors/actuators and industrial control systems. As a key component in ABB’s distributed automation portfolio, this module specializes in converting, conditioning, and transmitting analog signals, ensuring accurate data flow in processes where precise measurement and control are paramount.

What distinguishes the S-053M 3BHB012897R0003 is its hybrid design, combining 8 analog inputs and 4 analog outputs in a compact form factor. This versatility allows it to handle diverse signals—from pressure and temperature sensors (4-20 mA) to voltage-based transducers (0-10 V DC)—while providing conditioned outputs for actuators like control valves or variable speed drives. Equipped with MODBUS RTU communication, the S-053M 3BHB012897R0003 seamlessly integrates with ABB’s AC 800M DCS and third-party PLCs, making it ideal for applications in chemical processing, oil and gas, and power generation where signal integrity directly impacts process efficiency and safety.

Core advantages and technical highlights

High-precision signal handling: The S-053M 3BHB012897R0003 delivers 16-bit resolution and ±0.1% full-scale accuracy, ensuring reliable measurement of subtle signal variations—critical for applications like pH control in chemical reactors, where even a 0.1 pH shift can affect product quality. Its advanced filtering algorithms minimize noise from industrial environments, maintaining signal integrity even near high-voltage equipment or variable frequency drives.

Flexible signal conversion: Supporting both 4-20 mA and 0-10 V DC signals on input and output channels, the S-053M 3BHB012897R0003 adapts to diverse field devices without requiring external converters. For example, in a water treatment plant, it can accept 4-20 mA signals from turbidity sensors and output 0-10 V commands to chemical dosing pumps, streamlining system architecture and reducing component count.

Robust isolation and noise immunity: With 2.5 kV AC isolation between channels and the backplane, the S-053M 3BHB012897R0003 protects sensitive control systems from ground loops and voltage transients common in industrial settings. This isolation, combined with shielded internal circuitry, ensures stable operation in electrically noisy environments such as steel mills or mining operations, where electromagnetic interference (EMI) can corrupt analog signals.

Efficient integration and diagnostics: The module’s MODBUS RTU interface enables remote configuration, calibration, and diagnostics, reducing the need for on-site adjustments. Maintenance teams can monitor channel-specific health data—such as signal strength and drift—via the control system HMI, allowing proactive identification of aging sensors or cabling issues. This capability minimizes unplanned downtime in continuous processes like oil refining.

Typical application scenarios

In chemical processing plants, the S-053M 3BHB012897R0003 plays a vital role in batch reactor control. It receives 4-20 mA signals from temperature, pressure, and level sensors within the reactor, conditioning them for the PLC. The module then outputs 4-20 mA commands to control valves regulating steam flow and chemical additions. Its high accuracy ensures temperature is maintained within ±0.5°C of the setpoint, critical for reactions sensitive to thermal variations, while isolation prevents ground loops from disrupting measurements.

In power generation facilities, the S-053M 3BHB012897R0003 monitors and controls boiler feedwater systems. It processes 4-20 mA signals from flow meters and conductivity sensors, providing real-time data to the DCS. The module’s outputs adjust the speed of feedwater pumps via 0-10 V signals to maintain optimal water levels and purity. Its wide operating temperature range (-20°C to 60°C) allows reliable operation in the harsh environment of boiler rooms, where temperature fluctuations are common.

ABB S-053M 3BHB012897R0003

Related model recommendations

S-053L 3BHB012896R0003: A lower-channel variant of the S-053M 3BHB012897R0003 with 4 inputs and 2 outputs, suitable for smaller systems.

S-053H 3BHB012898R0003: A high-density version with 16 inputs and 8 outputs, ideal for large-scale process skids.

CI853A 3BSE018105R1: A MODBUS-to-PROFINET gateway that integrates the S-053M 3BHB012897R0003 into Ethernet-based control networks.

AC 800M 3BSE013236R1: A controller optimized to work with the S-053M 3BHB012897R0003 for advanced process control algorithms.

TB857 3BSE013269R1: A surge protection terminal block that enhances the S-053M 3BHB012897R0003’s noise immunity in high-EMI environments.

GDD471A001: A digital output module that complements the S-053M 3BHB012897R0003 for mixed analog/digital control loops.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the S-053M 3BHB012897R0003, ensure the DIN rail is securely mounted in a control cabinet with ambient temperature between -20°C and 60°C. Verify the 24 V DC power supply has ripple ≤50 mV to avoid signal interference. Use shielded twisted-pair cables (0.5 mm²) for analog signals, grounding the shield at the module end only to prevent ground loops. Required tools include a torque screwdriver (0.4-0.6 Nm), wire strippers, and a precision multimeter for calibration. Avoid mounting near high-voltage cables or motor drives.

Maintenance suggestions: Inspect the S-053M 3BHB012897R0003 quarterly for loose terminal screws and dust accumulation, cleaning with compressed air if necessary. Calibrate the module semi-annually using a precision signal generator, verifying input accuracy across the 4-20 mA and 0-10 V ranges. Check MODBUS communication monthly using a protocol analyzer to ensure data transmission errors are below 0.1%. If a channel exhibits drift beyond ±0.2% of full scale, recalibrate; replace the module if issues persist. Store spare modules in anti-static packaging at -25°C to 70°C, avoiding exposure to moisture.

Service and guarantee commitment

The S-053M 3BHB012897R0003 comes with a 5-year warranty from the installation date, covering manufacturing defects and ensuring compliance with published accuracy specifications. ABB guarantees replacement of faulty units within 72 hours for critical applications, minimizing downtime in process-critical control loops. Technical support is available 24/7 via ABB’s global network of automation specialists, offering assistance with calibration, configuration, and troubleshooting. Extended service contracts include annual calibration, preventive maintenance, and priority support, ensuring the S-053M 3BHB012897R0003 delivers reliable signal processing throughout its 10-year design lifespan. Customers also gain access to online resources, including calibration procedures and MODBUS register maps specific to this model.