Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

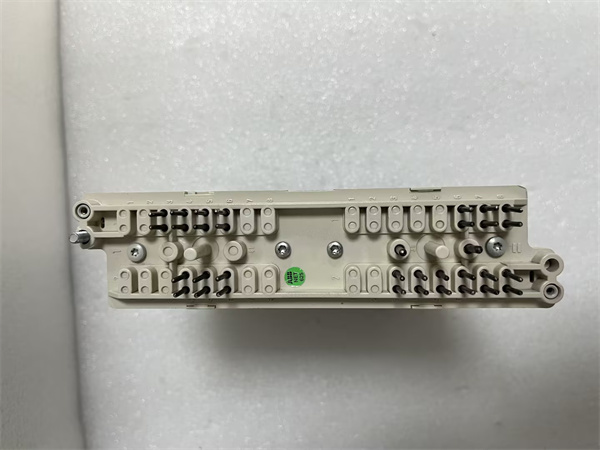

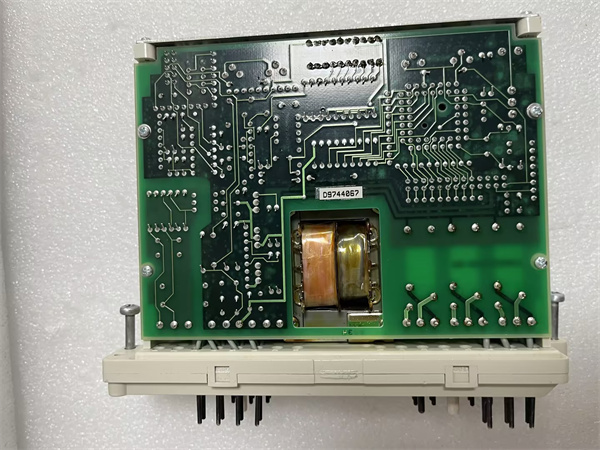

| Product Model | RXIDK 2H 1MRK000838-HA |

| Manufacturer | ABB |

| Product Category | Differential Protection Relay (Relion 670 Series) |

| Protection Functions | High-Impedance Differential (87H), Restricted Earth Fault (64REF) |

| Rated Current | 1 A / 5 A (configurable) |

| Operating Voltage | 48-250 VDC / 100-240 VAC |

| Fault Detection Time | <15 ms (typical) |

| Communication Protocols | IEC 61850 Ed.2, Modbus TCP, DNP3.0 |

| I/O Capacity | 16 binary inputs / 10 relay outputs |

| Operating Temperature | -40°C to +70°C |

| Certifications | IEC 60255, IEEE C37.90, SIL 2 |

| Front Panel Interface | 5″ LCD with tactile keys |

ABB RXIDK 2H 1MRK000838-HA

Product Introduction

The ABB RXIDK 2H 1MRK000838-HA is an advanced high-impedance differential protection relay from ABB’s Relion 670 series, engineered for critical power system assets. Designed specifically for busbar, transformer, and generator protection, this device implements 87H differential protection with precision stability during external faults. As part of ABB’s flagship protection portfolio, the RXIDK 2H integrates with Substation Automation Systems via IEC 61850-8-1 communication, providing real-time fault analysis and coordination capabilities.

Featuring adaptive harmonic restraint and CT saturation detection algorithms, the relay prevents maloperation during transformer inrush or CT saturation scenarios. Its 1MRK000838-HA hardware variant includes reinforced electromagnetic compatibility (EMC) for substation environments, with 4kV surge immunity per IEC 61000-4-5. The RXIDK 2H serves as the cornerstone for selective fault clearance in medium-to-high voltage networks, reducing equipment damage and minimizing outage times.

Core Advantages and Technical Highlights

Ultra-Rapid Fault Clearing:

Multi-criteria differential algorithm with ¼-cycle DFT computation detects internal faults in <15 ms. Adaptive 2nd/5th harmonic blocking ensures security during magnetizing inrush (sensitivity: 0.2I_n).

Cyber-Resilient Operation:

Hardware-based security module supports:

Role-based access control (RBAC)

Signed firmware packages

GOOSE message authentication

Audit trail per IEC 62351

Adaptive CT Supervision:

Auto-compensation for CT ratio mismatches (up to 2:1). Continuous monitoring of CT health with saturation prediction alerts via PCM600 software.

Extreme Environment Readiness:

-40°C cold-start capability (IEC 60068-2-1). Vibration resistance: 3g @ 10-150Hz (IEC 60255-21-1). Conformal coating protects against H₂S corrosion.

Typical Application Scenarios

The ABB RXIDK 2H 1MRK000838-HA protects critical infrastructure including:

Substation Busbars: Selective zone protection in 132kV GIS switchgear with IEC 61850-9-2LE process bus

Power Transformers: Differential protection for 500MVA units with harmonic restraint during energization

Hydro Generators: Stator ground fault detection with <3% sensitivity

Industrial Plants: Mission-critical process bus protection in steel mill arc furnace applications

Data Centers: 33kV main incomer protection with seamless integration to ABB Ability™ Energy Manager

ABB RXIDK 2H 1MRK000838-HA

Related Model Recommendations

REB670: Busbar protection relay with zone selectivity logic

RET670: Transformer-specific differential protection

REC670: Generator protection complementing RXIDK 2H

REF615: Feeder protection for downstream coordination

SMT IO-4: Merging unit for non-conventional instrument transformers

CMC356: Test kit for relay commissioning

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Verify CT knee-point voltage >2× relay setting. Use 2.5mm² shielded control cables with separate conduits for I/O. Ground shield at relay panel only. Maintain 100mm clearance from power cables.

Maintenance Protocol:

Biannual:

Verify settings via PCM600 (checksum validation)

Test binary inputs with 80% rated voltage

Measure operating time at 2× pickup current

Annual:

CT loop resistance measurement

Insulation resistance test (>100 MΩ at 1kVDC)

Cyber security audit per IEC 62443

Service and Guarantee Commitment

ABB provides:

60-month warranty covering hardware and protection algorithms

Lifecycle Commitment: 20-year spare availability guarantee

24/7 Grid Emergency Support: Dedicated power systems engineers

Cyber Security Updates: Annual vulnerability patches via ABB Ability™ Portal

On-site Calibration: Accredited services per ISO/IEC 17025

All relays undergo 2000-operation endurance testing and 72-hour burn-in at 85°C. SIL 2 certification includes third-party validation reports.